PDF Publication Title:

Text from PDF Page: 009

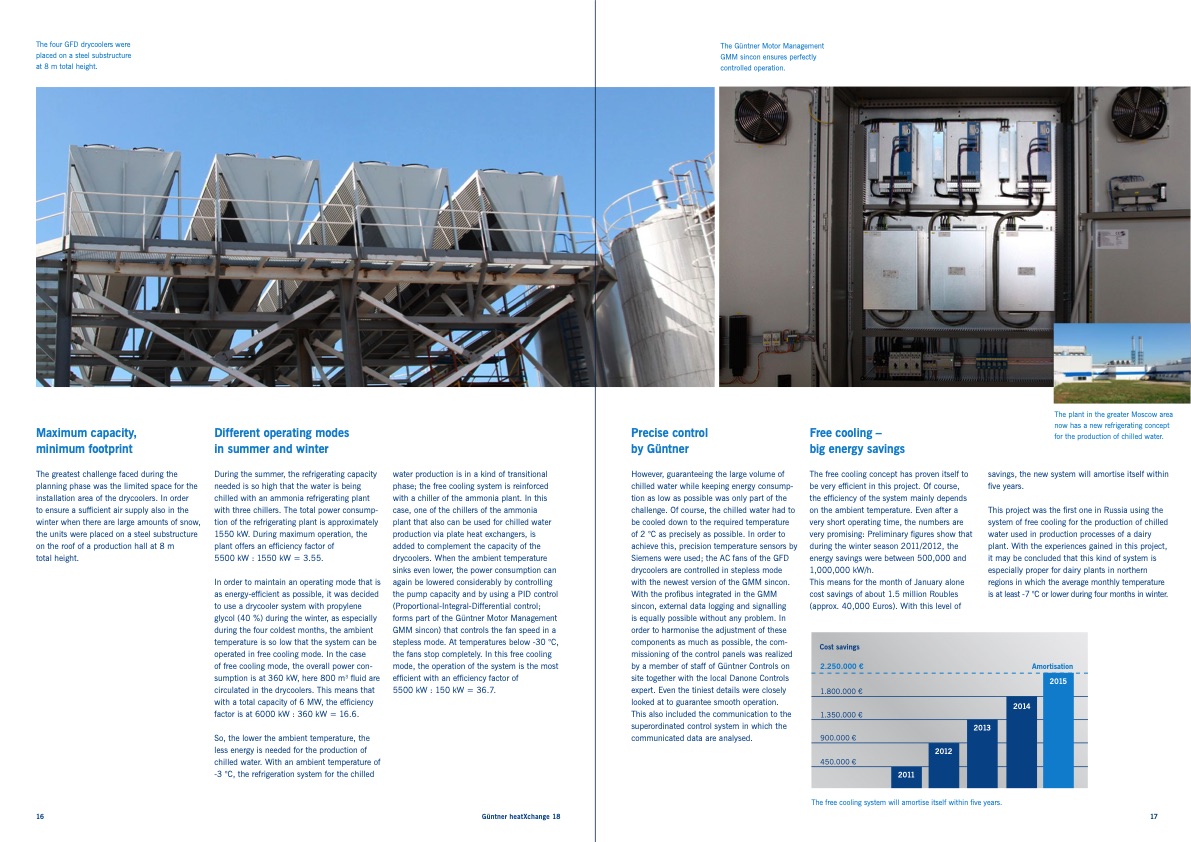

The four GFD drycoolers were placed on a steel substructure at 8 m total height. Maximum capacity, minimum footprint The greatest challenge faced during the planning phase was the limited space for the installation area of the drycoolers. In order to ensure a sufficient air supply also in the winter when there are large amounts of snow, the units were placed on a steel substructure on the roof of a production hall at 8 m total height. Different operating modes in summer and winter During the summer, the refrigerating capacity needed is so high that the water is being chilled with an ammonia refrigerating plant with three chillers. The total power consump- tion of the refrigerating plant is approximately 1550 kW. During maximum operation, the plant offers an efficiency factor of 5500 kW : 1550 kW = 3.55. In order to maintain an operating mode that is as energy-efficient as possible, it was decided to use a drycooler system with propylene glycol (40 %) during the winter, as especially during the four coldest months, the ambient temperature is so low that the system can be operated in free cooling mode. In the case of free cooling mode, the overall power con- sumption is at 360 kW, here 800 m3 fluid are circulated in the drycoolers. This means that with a total capacity of 6 MW, the efficiency factor is at 6000 kW : 360 kW = 16.6. So, the lower the ambient temperature, the less energy is needed for the production of chilled water. With an ambient temperature of -3 °C, the refrigeration system for the chilled water production is in a kind of transitional phase; the free cooling system is reinforced with a chiller of the ammonia plant. In this case, one of the chillers of the ammonia plant that also can be used for chilled water production via plate heat exchangers, is added to complement the capacity of the drycoolers. When the ambient temperature sinks even lower, the power consumption can again be lowered considerably by controlling the pump capacity and by using a PID control (Proportional-Integral-Differential control; forms part of the Güntner Motor Management GMM sincon) that controls the fan speed in a stepless mode. At temperatures below -30 °C, the fans stop completely. In this free cooling mode, the operation of the system is the most efficient with an efficiency factor of 5500 kW : 150 kW = 36.7. 16 Güntner heatXchange 18 The Güntner Motor Management GMM sincon ensures perfectly controlled operation. Precise control by Güntner However, guaranteeing the large volume of chilled water while keeping energy consump- tion as low as possible was only part of the challenge. Of course, the chilled water had to be cooled down to the required temperature of 2 °C as precisely as possible. In order to achieve this, precision temperature sensors by Siemens were used; the AC fans of the GFD drycoolers are controlled in stepless mode with the newest version of the GMM sincon. With the profibus integrated in the GMM sincon, external data logging and signalling is equally possible without any problem. In order to harmonise the adjustment of these components as much as possible, the com- missioning of the control panels was realized by a member of staff of Güntner Controls on site together with the local Danone Controls expert. Even the tiniest details were closely looked at to guarantee smooth operation. This also included the communication to the superordinated control system in which the communicated data are analysed. Free cooling – big energy savings The free cooling concept has proven itself to be very efficient in this project. Of course, the efficiency of the system mainly depends on the ambient temperature. Even after a very short operating time, the numbers are very promising: Preliminary figures show that during the winter season 2011/2012, the energy savings were between 500,000 and 1,000,000 kW/h. This means for the month of January alone cost savings of about 1.5 million Roubles (approx. 40,000 Euros). With this level of The plant in the greater Moscow area now has a new refrigerating concept for the production of chilled water. savings, the new system will amortise itself within five years. This project was the first one in Russia using the system of free cooling for the production of chilled water used in production processes of a dairy plant. With the experiences gained in this project, it may be concluded that this kind of system is especially proper for dairy plants in northern regions in which the average monthly temperature is at least -7 °C or lower during four months in winter. Cost savings 2.250.000 € Amortisation 1.800.000 € 2015 1.350.000 € 2014 900.000 € 2013 450.000 € 2012 2011 The free cooling system will amortise itself within five years. 17PDF Image | heat X Change

PDF Search Title:

heat X ChangeOriginal File Name Searched:

588_heatxchange_18_en_web.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |