PDF Publication Title:

Text from PDF Page: 009

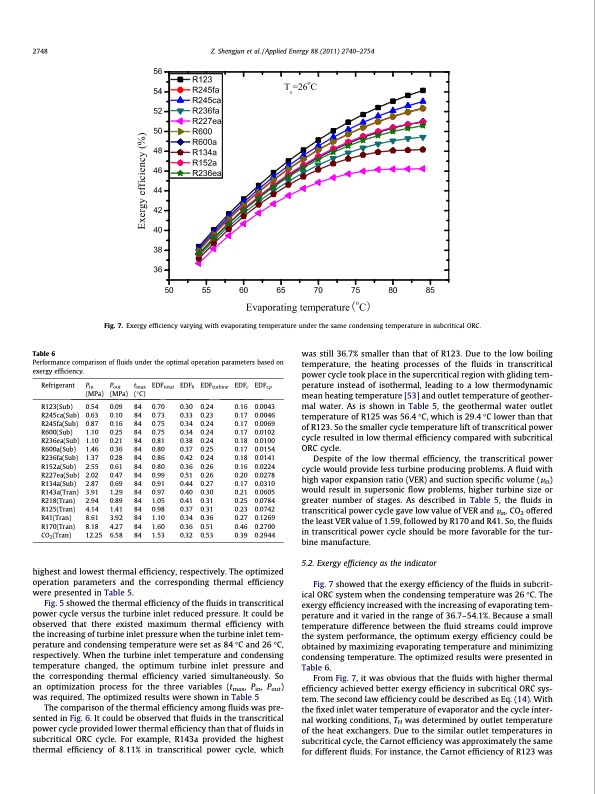

2748 Z. Shengjun et al. / Applied Energy 88 (2011) 2740–2754 Fig. 7. Exergy efficiency varying with evaporating temperature under the same condensing temperature in subcritical ORC. Table 6 Performance comparison of fluids under the optimal operation parameters based on exergy efficiency. was still 36.7% smaller than that of R123. Due to the low boiling temperature, the heating processes of the fluids in transcritical power cycle took place in the supercritical region with gliding tem- perature instead of isothermal, leading to a low thermodynamic mean heating temperature [53] and outlet temperature of geother- mal water. As is shown in Table 5, the geothermal water outlet temperature of R125 was 56.4 °C, which is 29.4 °C lower than that of R123. So the smaller cycle temperature lift of transcritical power cycle resulted in low thermal efficiency compared with subcritical ORC cycle. Despite of the low thermal efficiency, the transcritical power cycle would provide less turbine producing problems. A fluid with high vapor expansion ratio (VER) and suction specific volume (vin) would result in supersonic flow problems, higher turbine size or greater number of stages. As described in Table 5, the fluids in transcritical power cycle gave low value of VER and vin. CO2 offered the least VER value of 1.59, followed by R170 and R41. So, the fluids in transcritical power cycle should be more favorable for the tur- bine manufacture. 5.2. Exergy efficiency as the indicator Fig. 7 showed that the exergy efficiency of the fluids in subcrit- ical ORC system when the condensing temperature was 26 °C. The exergy efficiency increased with the increasing of evaporating tem- perature and it varied in the range of 36.7–54.1%. Because a small temperature difference between the fluid streams could improve the system performance, the optimum exergy efficiency could be obtained by maximizing evaporating temperature and minimizing condensing temperature. The optimized results were presented in Table 6. From Fig. 7, it was obvious that the fluids with higher thermal efficiency achieved better exergy efficiency in subcritical ORC sys- tem. The second law efficiency could be described as Eq. (14). With the fixed inlet water temperature of evaporator and the cycle inter- nal working conditions, TH was determined by outlet temperature of the heat exchangers. Due to the similar outlet temperatures in subcritical cycle, the Carnot efficiency was approximately the same for different fluids. For instance, the Carnot efficiency of R123 was Refrigerant R123(Sub) R245ca(Sub) R245fa(Sub) R600(Sub) R236ea(Sub) R600a(Sub) R236fa(Sub) R152a(Sub) R227ea(Sub) R134a(Sub) R143a(Tran) R218(Tran) R125(Tran) R41(Tran) R170(Tran) CO2(Tran) Pin Pout tmax (MPa) (MPa) (°C) 0.54 0.09 84 0.63 0.10 84 0.87 0.16 84 1.10 0.25 84 1.10 0.21 84 1.46 0.36 84 1.37 0.28 84 2.55 0.61 84 2.02 0.47 84 2.87 0.69 84 3.91 1.29 84 2.94 0.89 84 4.14 1.41 84 8.61 3.92 84 8.18 4.27 84 12.25 6.58 84 EDFtotal EDFh EDFturbine EDFc 0.70 0.30 0.24 0.16 0.73 0.33 0.23 0.17 0.75 0.34 0.24 0.17 0.75 0.34 0.24 0.17 0.81 0.38 0.24 0.18 0.80 0.37 0.25 0.17 0.86 0.42 0.24 0.18 0.80 0.36 0.26 0.16 0.99 0.51 0.26 0.20 0.91 0.44 0.27 0.17 0.97 0.40 0.30 0.21 1.05 0.41 0.31 0.25 0.98 0.37 0.31 0.23 1.10 0.34 0.36 0.27 1.60 0.36 0.51 0.46 1.53 0.32 0.53 0.39 EDFr,p 0.0043 0.0046 0.0069 0.0102 0.0100 0.0154 0.0141 0.0224 0.0278 0.0310 0.0605 0.0784 0.0742 0.1269 0.2700 0.2944 highest and lowest thermal efficiency, respectively. The optimized operation parameters and the corresponding thermal efficiency were presented in Table 5. Fig. 5 showed the thermal efficiency of the fluids in transcritical power cycle versus the turbine inlet reduced pressure. It could be observed that there existed maximum thermal efficiency with the increasing of turbine inlet pressure when the turbine inlet tem- perature and condensing temperature were set as 84 °C and 26 °C, respectively. When the turbine inlet temperature and condensing temperature changed, the optimum turbine inlet pressure and the corresponding thermal efficiency varied simultaneously. So an optimization process for the three variables (tmax, Pin, Pout) was required. The optimized results were shown in Table 5 The comparison of the thermal efficiency among fluids was pre- sented in Fig. 6. It could be observed that fluids in the transcritical power cycle provided lower thermal efficiency than that of fluids in subcritical ORC cycle. For example, R143a provided the highest thermal efficiency of 8.11% in transcritical power cycle, whichPDF Image | Performance comparison and parametric optimization of subcritical Organic Rankine Cycle (ORC) and transcritical power cycle system for low-temperature geothermal power generation

PDF Search Title:

Performance comparison and parametric optimization of subcritical Organic Rankine Cycle (ORC) and transcritical power cycle system for low-temperature geothermal power generationOriginal File Name Searched:

2011___S._Zang___Performance_comparison_and_parametric_optimization_of_subcritical_and_transcritical.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |