PDF Publication Title:

Text from PDF Page: 004

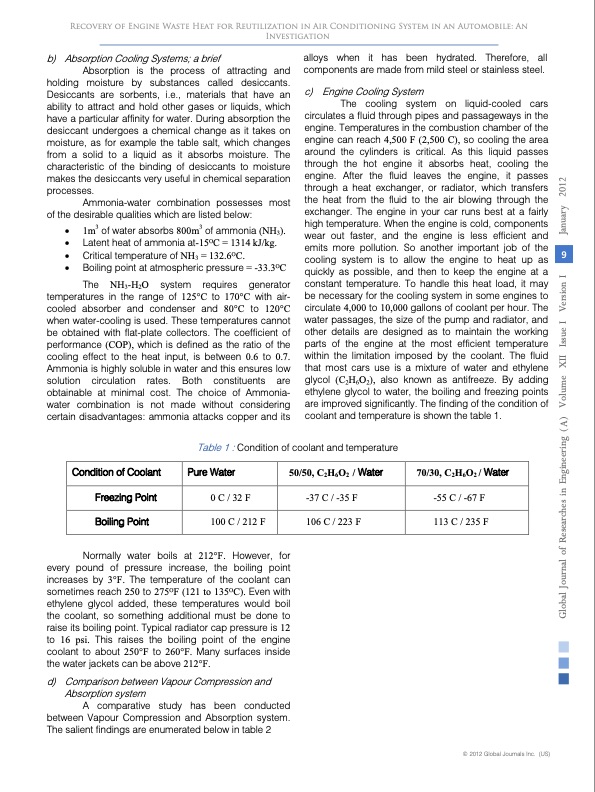

Recovery of Engine Waste Heat for Reutilization in Air Conditioning System in an Automobile: An Investigation b) Absorption Cooling Systems; a brief Absorption is the process of attracting and holding moisture by substances called desiccants. Desiccants are sorbents, i.e., materials that have an ability to attract and hold other gases or liquids, which have a particular affinity for water. During absorption the desiccant undergoes a chemical change as it takes on moisture, as for example the table salt, which changes from a solid to a liquid as it absorbs moisture. The characteristic of the binding of desiccants to moisture makes the desiccants very useful in chemical separation processes. Ammonia-water combination possesses most of the desirable qualities which are listed below: • 1m3 of water absorbs 800m3 of ammonia (NH3). • Latent heat of ammonia at-15OC = 1314 kJ/kg. • Critical temperature of NH3 = 132.6OC. • Boiling point at atmospheric pressure = -33.3OC The NH3-H2O system requires generator temperatures in the range of 125°C to 170°C with air- cooled absorber and condenser and 80°C to 120°C when water-cooling is used. These temperatures cannot be obtained with flat-plate collectors. The coefficient of performance (COP), which is defined as the ratio of the cooling effect to the heat input, is between 0.6 to 0.7. Ammonia is highly soluble in water and this ensures low solution circulation rates. Both constituents are obtainable at minimal cost. The choice of Ammonia- water combination is not made without considering certain disadvantages: ammonia attacks copper and its alloys when it has been hydrated. Therefore, all components are made from mild steel or stainless steel. c) Engine Cooling System The cooling system on liquid-cooled cars circulates a fluid through pipes and passageways in the engine. Temperatures in the combustion chamber of the engine can reach 4,500 F (2,500 C), so cooling the area around the cylinders is critical. As this liquid passes through the hot engine it absorbs heat, cooling the engine. After the fluid leaves the engine, it passes through a heat exchanger, or radiator, which transfers the heat from the fluid to the air blowing through the exchanger. The engine in your car runs best at a fairly high temperature. When the engine is cold, components wear out faster, and the engine is less efficient and emits more pollution. So another important job of the cooling system is to allow the engine to heat up as 9 quickly as possible, and then to keep the engine at a constant temperature. To handle this heat load, it may be necessary for the cooling system in some engines to circulate 4,000 to 10,000 gallons of coolant per hour. The water passages, the size of the pump and radiator, and other details are designed as to maintain the working parts of the engine at the most efficient temperature within the limitation imposed by the coolant. The fluid that most cars use is a mixture of water and ethylene glycol (C2H6O2), also known as antifreeze. By adding ethylene glycol to water, the boiling and freezing points are improved significantly. The finding of the condition of coolant and temperature is shown the table 1. Table 1 : Condition of coolant and temperature Condition of Coolant Freezing Point Boiling Point Pure Water 0 C / 32 F 100 C / 212 F 50/50, C2H6O2 / Water -37 C / -35 F 106 C / 223 F 70/30, C2H6O2 / Water -55 C / -67 F 113 C / 235 F Normally water boils at 212°F. However, for every pound of pressure increase, the boiling point increases by 3°F. The temperature of the coolant can sometimes reach 250 to 275OF (121 to 135OC). Even with ethylene glycol added, these temperatures would boil the coolant, so something additional must be done to raise its boiling point. Typical radiator cap pressure is 12 to 16 psi. This raises the boiling point of the engine coolant to about 250°F to 260°F. Many surfaces inside the water jackets can be above 212°F. d) Comparison between Vapour Compression and Absorption system A comparative study has been conducted between Vapour Compression and Absorption system. The salient findings are enumerated below in table 2 © 2012 Global Journals Inc. (US) Global Journal of Researches in Engineering (A ) Volume XII Issue vvvvI Version I January 2012PDF Image | Recovery of Engine Waste Heat for Reutilization in Air

PDF Search Title:

Recovery of Engine Waste Heat for Reutilization in AirOriginal File Name Searched:

2_Recovery_of_Engine_Waste_Heat_for_Reutilization.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |