PDF Publication Title:

Text from PDF Page: 011

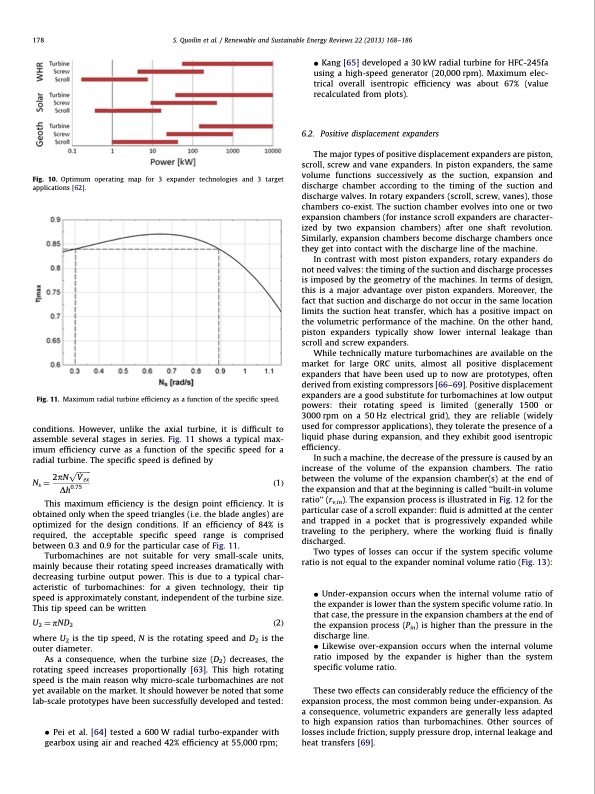

178 S. Quoilin et al. / Renewable and Sustainable Energy Reviews 22 (2013) 168–186 Fig. 10. Optimum operating map for 3 expander technologies and 3 target applications [62]. Fig. 11. Maximum radial turbine efficiency as a function of the specific speed. conditions. However, unlike the axial turbine, it is difficult to assemble several stages in series. Fig. 11 shows a typical max- imum efficiency curve as a function of the specific speed for a radial turbine. The specific speed is defined by pffiffiffiffiffiffiffi Ns1⁄42pNV_ex ð1Þ Dh0:75 This maximum efficiency is the design point efficiency. It is obtained only when the speed triangles (i.e. the blade angles) are optimized for the design conditions. If an efficiency of 84% is required, the acceptable specific speed range is comprised between 0.3 and 0.9 for the particular case of Fig. 11. Turbomachines are not suitable for very small-scale units, mainly because their rotating speed increases dramatically with decreasing turbine output power. This is due to a typical char- acteristic of turbomachines: for a given technology, their tip speed is approximately constant, independent of the turbine size. This tip speed can be written U21⁄4pND2 ð2Þ where U2 is the tip speed, N is the rotating speed and D2 is the outer diameter. As a consequence, when the turbine size (D2) decreases, the rotating speed increases proportionally [63]. This high rotating speed is the main reason why micro-scale turbomachines are not yet available on the market. It should however be noted that some lab-scale prototypes have been successfully developed and tested: Pei et al. [64] tested a 600 W radial turbo-expander with gearbox using air and reached 42% efficiency at 55,000 rpm; Kang [65] developed a 30 kW radial turbine for HFC-245fa using a high-speed generator (20,000 rpm). Maximum elec- trical overall isentropic efficiency was about 67% (value recalculated from plots). 6.2. Positive displacement expanders The major types of positive displacement expanders are piston, scroll, screw and vane expanders. In piston expanders, the same volume functions successively as the suction, expansion and discharge chamber according to the timing of the suction and discharge valves. In rotary expanders (scroll, screw, vanes), those chambers co-exist. The suction chamber evolves into one or two expansion chambers (for instance scroll expanders are character- ized by two expansion chambers) after one shaft revolution. Similarly, expansion chambers become discharge chambers once they get into contact with the discharge line of the machine. In contrast with most piston expanders, rotary expanders do not need valves: the timing of the suction and discharge processes is imposed by the geometry of the machines. In terms of design, this is a major advantage over piston expanders. Moreover, the fact that suction and discharge do not occur in the same location limits the suction heat transfer, which has a positive impact on the volumetric performance of the machine. On the other hand, piston expanders typically show lower internal leakage than scroll and screw expanders. While technically mature turbomachines are available on the market for large ORC units, almost all positive displacement expanders that have been used up to now are prototypes, often derived from existing compressors [66–69]. Positive displacement expanders are a good substitute for turbomachines at low output powers: their rotating speed is limited (generally 1500 or 3000 rpm on a 50 Hz electrical grid), they are reliable (widely used for compressor applications), they tolerate the presence of a liquid phase during expansion, and they exhibit good isentropic efficiency. In such a machine, the decrease of the pressure is caused by an increase of the volume of the expansion chambers. The ratio between the volume of the expansion chamber(s) at the end of the expansion and that at the beginning is called ‘‘built-in volume ratio’’ (rv,in). The expansion process is illustrated in Fig. 12 for the particular case of a scroll expander: fluid is admitted at the center and trapped in a pocket that is progressively expanded while traveling to the periphery, where the working fluid is finally discharged. Two types of losses can occur if the system specific volume ratio is not equal to the expander nominal volume ratio (Fig. 13): Under-expansion occurs when the internal volume ratio of the expander is lower than the system specific volume ratio. In that case, the pressure in the expansion chambers at the end of the expansion process (Pin) is higher than the pressure in the discharge line. Likewise over-expansion occurs when the internal volume ratio imposed by the expander is higher than the system specific volume ratio. These two effects can considerably reduce the efficiency of the expansion process, the most common being under-expansion. As a consequence, volumetric expanders are generally less adapted to high expansion ratios than turbomachines. Other sources of losses include friction, supply pressure drop, internal leakage and heat transfers [69].PDF Image | Techno-economic survey of Organic Rankine Cycle (ORC) systems

PDF Search Title:

Techno-economic survey of Organic Rankine Cycle (ORC) systemsOriginal File Name Searched:

1_s2.0_S1364032113000592_main.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |