PDF Publication Title:

Text from PDF Page: 014

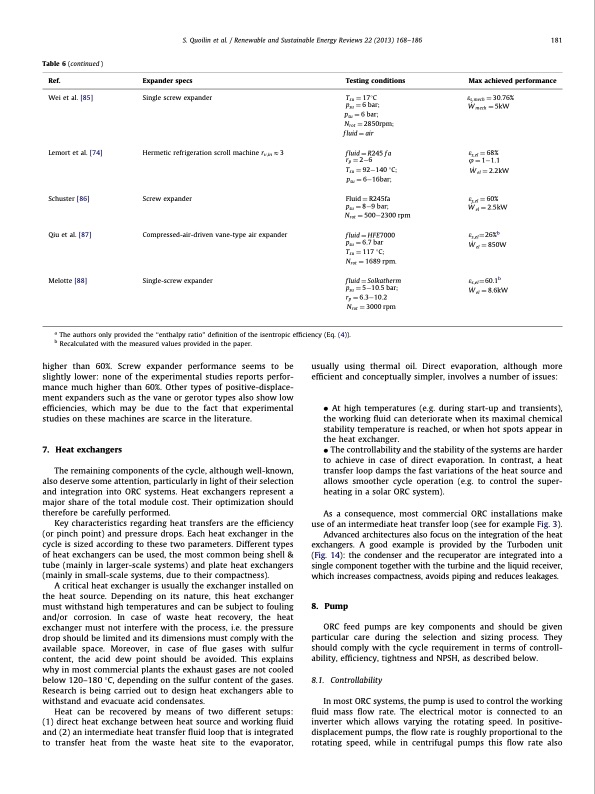

Table 6 (continued ) Ref. Wei et al. [85] Lemort et al. [74] Schuster [86] Qiu et al. [87] Melotte [88] Expander specs Single screw expander Hermetic refrigeration scroll machine rv,inE3 Screw expander Compressed-air-driven vane-type air expander Single-screw expander Testing conditions Tsu 1⁄4 171C psu 1⁄46bar; psu 1⁄4 6 bar; Nrot 1⁄4 2850rpm; f luid 1⁄4 air fluid1⁄4R245fa rp 1⁄426 Tsu 1⁄4 92140 1C; psu 1⁄4 616bar; Fluid 1⁄4 R245fa psu 1⁄4 89 bar; Nrot 1⁄4 5002300 rpm fluid 1⁄4 HFE7000 psu 1⁄46:7bar Tsu 1⁄41171C; Nrot 1⁄4 1689 rpm: f luid 1⁄4 Solkatherm psu 1⁄4 510:5 bar; rp 1⁄4 6:310:2 Nrot 1⁄4 3000 rpm Max achieved performance es,mech 1⁄4 30:76% W_ mech 1⁄45kW es,el 1⁄468% j1⁄411:1 W_ el 1⁄4 2:2kW es,el 1⁄4 60% W_ el 1⁄4 2:5kW es,el1⁄426%b W_ el 1⁄4850W es,el 1⁄4 60.1b W_ el 1⁄4 8:6kW S. Quoilin et al. / Renewable and Sustainable Energy Reviews 22 (2013) 168–186 181 a The authors only provided the ‘‘enthalpy ratio’’ definition of the isentropic efficiency (Eq. (4)). b Recalculated with the measured values provided in the paper. higher than 60%. Screw expander performance seems to be slightly lower: none of the experimental studies reports perfor- mance much higher than 60%. Other types of positive-displace- ment expanders such as the vane or gerotor types also show low efficiencies, which may be due to the fact that experimental studies on these machines are scarce in the literature. 7. Heat exchangers The remaining components of the cycle, although well-known, also deserve some attention, particularly in light of their selection and integration into ORC systems. Heat exchangers represent a major share of the total module cost. Their optimization should therefore be carefully performed. Key characteristics regarding heat transfers are the efficiency (or pinch point) and pressure drops. Each heat exchanger in the cycle is sized according to these two parameters. Different types of heat exchangers can be used, the most common being shell & tube (mainly in larger-scale systems) and plate heat exchangers (mainly in small-scale systems, due to their compactness). A critical heat exchanger is usually the exchanger installed on the heat source. Depending on its nature, this heat exchanger must withstand high temperatures and can be subject to fouling and/or corrosion. In case of waste heat recovery, the heat exchanger must not interfere with the process, i.e. the pressure drop should be limited and its dimensions must comply with the available space. Moreover, in case of flue gases with sulfur content, the acid dew point should be avoided. This explains why in most commercial plants the exhaust gases are not cooled below 120–180 1C, depending on the sulfur content of the gases. Research is being carried out to design heat exchangers able to withstand and evacuate acid condensates. Heat can be recovered by means of two different setups: (1) direct heat exchange between heat source and working fluid and (2) an intermediate heat transfer fluid loop that is integrated to transfer heat from the waste heat site to the evaporator, usually using thermal oil. Direct evaporation, although more efficient and conceptually simpler, involves a number of issues: At high temperatures (e.g. during start-up and transients), the working fluid can deteriorate when its maximal chemical stability temperature is reached, or when hot spots appear in the heat exchanger. The controllability and the stability of the systems are harder to achieve in case of direct evaporation. In contrast, a heat transfer loop damps the fast variations of the heat source and allows smoother cycle operation (e.g. to control the super- heating in a solar ORC system). As a consequence, most commercial ORC installations make use of an intermediate heat transfer loop (see for example Fig. 3). Advanced architectures also focus on the integration of the heat exchangers. A good example is provided by the Turboden unit (Fig. 14): the condenser and the recuperator are integrated into a single component together with the turbine and the liquid receiver, which increases compactness, avoids piping and reduces leakages. 8. Pump ORC feed pumps are key components and should be given particular care during the selection and sizing process. They should comply with the cycle requirement in terms of controll- ability, efficiency, tightness and NPSH, as described below. 8.1. Controllability In most ORC systems, the pump is used to control the working fluid mass flow rate. The electrical motor is connected to an inverter which allows varying the rotating speed. In positive- displacement pumps, the flow rate is roughly proportional to the rotating speed, while in centrifugal pumps this flow rate alsoPDF Image | Techno-economic survey of Organic Rankine Cycle (ORC) systems

PDF Search Title:

Techno-economic survey of Organic Rankine Cycle (ORC) systemsOriginal File Name Searched:

1_s2.0_S1364032113000592_main.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |