PDF Publication Title:

Text from PDF Page: 021

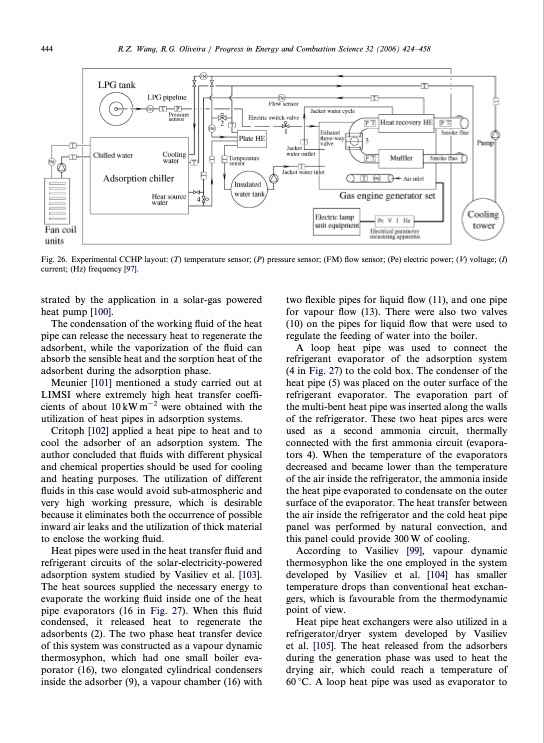

ARTICLE IN PRESS 444 R.Z. Wang, R.G. Oliveira / Progress in Energy and Combustion Science 32 (2006) 424–458 Fig. 26. Experimental CCHP layout: (T) temperature sensor; (P) pressure sensor; (FM) flow sensor; (Pe) electric power; (V) voltage; (I) current; (Hz) frequency [97]. strated by the application in a solar-gas powered heat pump [100]. The condensation of the working fluid of the heat pipe can release the necessary heat to regenerate the adsorbent, while the vaporization of the fluid can absorb the sensible heat and the sorption heat of the adsorbent during the adsorption phase. Meunier [101] mentioned a study carried out at LIMSI where extremely high heat transfer coeffi- cients of about 10 kW m2 were obtained with the utilization of heat pipes in adsorption systems. Critoph [102] applied a heat pipe to heat and to cool the adsorber of an adsorption system. The author concluded that fluids with different physical and chemical properties should be used for cooling and heating purposes. The utilization of different fluids in this case would avoid sub-atmospheric and very high working pressure, which is desirable because it eliminates both the occurrence of possible inward air leaks and the utilization of thick material to enclose the working fluid. Heat pipes were used in the heat transfer fluid and refrigerant circuits of the solar-electricity-powered adsorption system studied by Vasiliev et al. [103]. The heat sources supplied the necessary energy to evaporate the working fluid inside one of the heat pipe evaporators (16 in Fig. 27). When this fluid condensed, it released heat to regenerate the adsorbents (2). The two phase heat transfer device of this system was constructed as a vapour dynamic thermosyphon, which had one small boiler eva- porator (16), two elongated cylindrical condensers inside the adsorber (9), a vapour chamber (16) with two flexible pipes for liquid flow (11), and one pipe for vapour flow (13). There were also two valves (10) on the pipes for liquid flow that were used to regulate the feeding of water into the boiler. A loop heat pipe was used to connect the refrigerant evaporator of the adsorption system (4 in Fig. 27) to the cold box. The condenser of the heat pipe (5) was placed on the outer surface of the refrigerant evaporator. The evaporation part of the multi-bent heat pipe was inserted along the walls of the refrigerator. These two heat pipes arcs were used as a second ammonia circuit, thermally connected with the first ammonia circuit (evapora- tors 4). When the temperature of the evaporators decreased and became lower than the temperature of the air inside the refrigerator, the ammonia inside the heat pipe evaporated to condensate on the outer surface of the evaporator. The heat transfer between the air inside the refrigerator and the cold heat pipe panel was performed by natural convection, and this panel could provide 300 W of cooling. According to Vasiliev [99], vapour dynamic thermosyphon like the one employed in the system developed by Vasiliev et al. [104] has smaller temperature drops than conventional heat exchan- gers, which is favourable from the thermodynamic point of view. Heat pipe heat exchangers were also utilized in a refrigerator/dryer system developed by Vasiliev et al. [105]. The heat released from the adsorbers during the generation phase was used to heat the drying air, which could reach a temperature of 60 1C. A loop heat pipe was used as evaporator toPDF Image | Adsorption refrigeration

PDF Search Title:

Adsorption refrigerationOriginal File Name Searched:

2008519283773463.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |