PDF Publication Title:

Text from PDF Page: 006

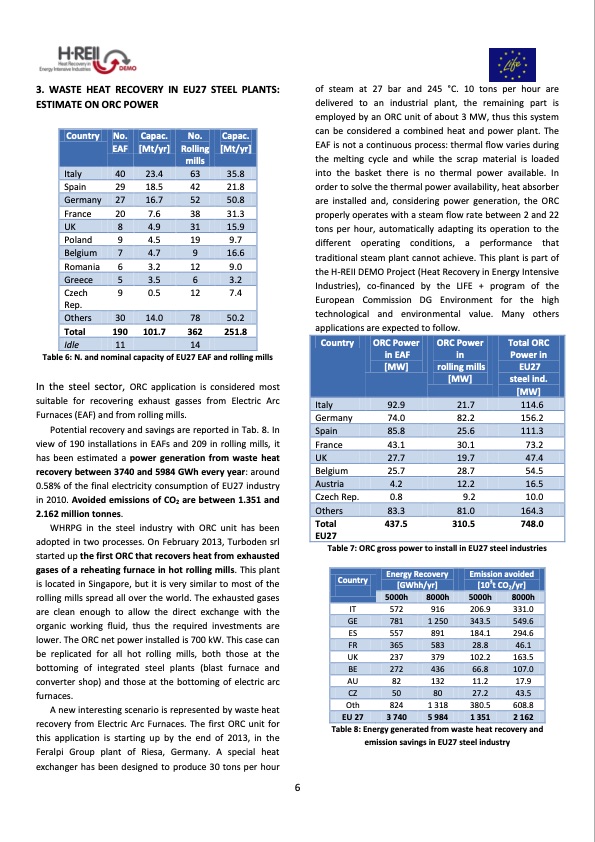

3. WASTE HEAT RECOVERY IN EU27 STEEL PLANTS: ESTIMATE ON ORC POWER of steam at 27 bar and 245 °C. 10 tons per hour are delivered to an industrial plant, the remaining part is employed by an ORC unit of about 3 MW, thus this system can be considered a combined heat and power plant. The EAF is not a continuous process: thermal flow varies during the melting cycle and while the scrap material is loaded into the basket there is no thermal power available. In order to solve the thermal power availability, heat absorber are installed and, considering power generation, the ORC properly operates with a steam flow rate between 2 and 22 tons per hour, automatically adapting its operation to the different operating conditions, a performance that traditional steam plant cannot achieve. This plant is part of the H-REII DEMO Project (Heat Recovery in Energy Intensive Industries), co-financed by the LIFE + program of the European Commission DG Environment for the high technological and environmental value. Many others applications are expected to follow. Germany 74.0 82.2 156.2 111.3 France 43.1 30.1 73.2 UK 27.7 19.7 47.4 Belgium 25.7 28.7 54.5 Austria 4.2 12.2 16.5 Czech Rep. 0.8 9.2 10.0 Others 83.3 81.0 164.3 Total 437.5 310.5 748.0 EU27 Table 7: ORC gross power to install in EU27 steel industries Energy Recovery [GWhh/yr] 5000h 8000h 572 916 781 1 250 557 891 365 583 237 379 272 436 82 132 50 80 824 1 318 3 740 5 984 No. EAF 40 Spain 29 18.5 42 21.8 Country Capac. [Mt/yr] No. Rolling mills Capac. [Mt/yr] Italy 23.4 63 35.8 16.7 52 50.8 Germany 27 France 20 7.6 38 31.3 UK 8 Poland 9 4.5 19 9.7 Belgium 7 Romania 6 3.2 12 9.0 Greece 5 Czech 9 0.5 12 7.4 Rep. Others 30 Total 190 101.7 362 Idle 11 4.9 31 15.9 4.7 9 16.6 3.5 6 3.2 14.0 78 50.2 251.8 Table 6: N. and nominal capacity of EU27 EAF and rolling mills In the steel sector, ORC application is considered most suitable for recovering exhaust gasses from Electric Arc Furnaces (EAF) and from rolling mills. Potential recovery and savings are reported in Tab. 8. In view of 190 installations in EAFs and 209 in rolling mills, it has been estimated a power generation from waste heat recovery between 3740 and 5984 GWh every year: around 0.58% of the final electricity consumption of EU27 industry in 2010. Avoided emissions of CO2 are between 1.351 and 2.162 million tonnes. WHRPG in the steel industry with ORC unit has been adopted in two processes. On February 2013, Turboden srl started up the first ORC that recovers heat from exhausted gases of a reheating furnace in hot rolling mills. This plant is located in Singapore, but it is very similar to most of the rolling mills spread all over the world. The exhausted gases are clean enough to allow the direct exchange with the organic working fluid, thus the required investments are lower. The ORC net power installed is 700 kW. This case can be replicated for all hot rolling mills, both those at the bottoming of integrated steel plants (blast furnace and converter shop) and those at the bottoming of electric arc furnaces. A new interesting scenario is represented by waste heat recovery from Electric Arc Furnaces. The first ORC unit for this application is starting up by the end of 2013, in the Feralpi Group plant of Riesa, Germany. A special heat exchanger has been designed to produce 30 tons per hour Country IT GE ES FR UK BE AU CZ Oth EU 27 Emission avoided [103t CO2/yr] 14 Spain 85.8 25.6 5000h 206.9 343.5 184.1 28.8 102.2 66.8 11.2 27.2 380.5 1 351 8000h 331.0 549.6 294.6 46.1 163.5 107.0 17.9 43.5 608.8 2 162 6 Country ORC Power in EAF [MW] ORC Power in rolling mills [MW] Table 8: Energy generated from waste heat recovery and emission savings in EU27 steel industry Total ORC Power in EU27 steel ind. [MW] Italy 92.9 21.7 114.6PDF Image | ORC WASTE HEAT RECOVERY IN EUROPEAN ENERGY

PDF Search Title:

ORC WASTE HEAT RECOVERY IN EUROPEAN ENERGYOriginal File Name Searched:

Annex_4II_EU_paper_def.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |