PDF Publication Title:

Text from PDF Page: 007

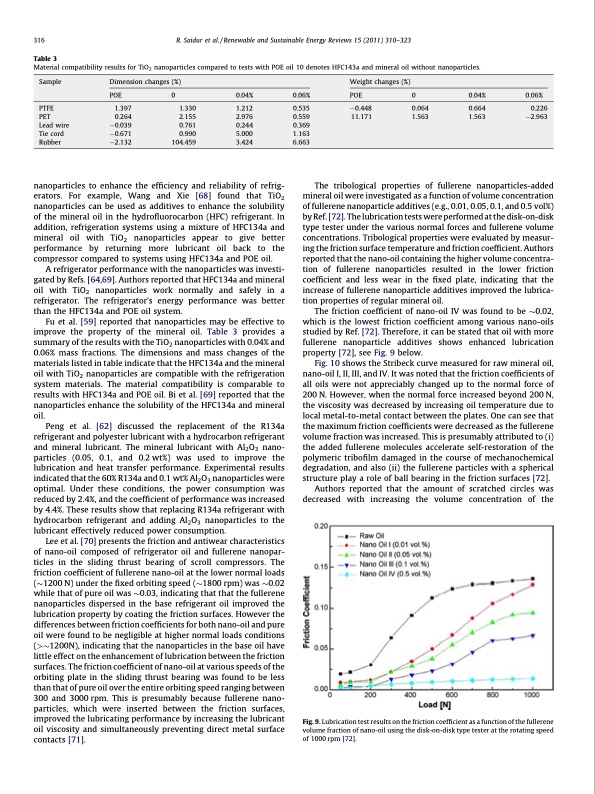

316 R. Saidur et al. / Renewable and Sustainable Energy Reviews 15 (2011) 310–323 Table 3 Material compatibility results for TiO2 nanoparticles compared to tests with POE oil 10 denotes HFC143a and mineral oil without nanoparticles. Sample Dimension changes (%) Weight changes (%) POE 0 0.04% 0.06% POE 0 0.04% 0.06% PTFE 1.397 PET 0.264 Lead wire 0.039 Tie cord 0.671 Rubber 2.132 1.330 1.212 2.155 2.976 0.761 0.244 0.990 5.000 104.459 3.424 0.535 0.448 0.064 0.664 0.226 0.559 11.171 1.563 1.563 2.963 0.369 1.163 6.663 nanoparticles to enhance the efficiency and reliability of refrig- erators. For example, Wang and Xie [68] found that TiO2 nanoparticles can be used as additives to enhance the solubility of the mineral oil in the hydrofluorocarbon (HFC) refrigerant. In addition, refrigeration systems using a mixture of HFC134a and mineral oil with TiO2 nanoparticles appear to give better performance by returning more lubricant oil back to the compressor compared to systems using HFC134a and POE oil. A refrigerator performance with the nanoparticles was investi- gated by Refs. [64,69]. Authors reported that HFC134a and mineral oil with TiO2 nanoparticles work normally and safely in a refrigerator. The refrigerator’s energy performance was better than the HFC134a and POE oil system. Fu et al. [59] reported that nanoparticles may be effective to improve the property of the mineral oil. Table 3 provides a summary of the results with the TiO2 nanoparticles with 0.04% and 0.06% mass fractions. The dimensions and mass changes of the materials listed in table indicate that the HFC134a and the mineral oil with TiO2 nanoparticles are compatible with the refrigeration system materials. The material compatibility is comparable to results with HFC134a and POE oil. Bi et al. [69] reported that the nanoparticles enhance the solubility of the HFC134a and mineral oil. Peng et al. [62] discussed the replacement of the R134a refrigerant and polyester lubricant with a hydrocarbon refrigerant and mineral lubricant. The mineral lubricant with Al2O3 nano- particles (0.05, 0.1, and 0.2wt%) was used to improve the lubrication and heat transfer performance. Experimental results indicated that the 60% R134a and 0.1 wt% Al2O3 nanoparticles were optimal. Under these conditions, the power consumption was reduced by 2.4%, and the coefficient of performance was increased by 4.4%. These results show that replacing R134a refrigerant with hydrocarbon refrigerant and adding Al2O3 nanoparticles to the lubricant effectively reduced power consumption. Lee et al. [70] presents the friction and antiwear characteristics of nano-oil composed of refrigerator oil and fullerene nanopar- ticles in the sliding thrust bearing of scroll compressors. The friction coefficient of fullerene nano-oil at the lower normal loads (1200 N) under the fixed orbiting speed (1800 rpm) was 0.02 while that of pure oil was 0.03, indicating that that the fullerene nanoparticles dispersed in the base refrigerant oil improved the lubrication property by coating the friction surfaces. However the differences between friction coefficients for both nano-oil and pure oil were found to be negligible at higher normal loads conditions (>1200N), indicating that the nanoparticles in the base oil have little effect on the enhancement of lubrication between the friction surfaces. The friction coefficient of nano-oil at various speeds of the orbiting plate in the sliding thrust bearing was found to be less than that of pure oil over the entire orbiting speed ranging between 300 and 3000 rpm. This is presumably because fullerene nano- particles, which were inserted between the friction surfaces, improved the lubricating performance by increasing the lubricant oil viscosity and simultaneously preventing direct metal surface contacts [71]. The tribological properties of fullerene nanoparticles-added mineral oil were investigated as a function of volume concentration of fullerene nanoparticle additives (e.g., 0.01, 0.05, 0.1, and 0.5 vol%) by Ref. [72]. The lubrication tests were performed at the disk-on-disk type tester under the various normal forces and fullerene volume concentrations. Tribological properties were evaluated by measur- ing the friction surface temperature and friction coefficient. Authors reported that the nano-oil containing the higher volume concentra- tion of fullerene nanoparticles resulted in the lower friction coefficient and less wear in the fixed plate, indicating that the increase of fullerene nanoparticle additives improved the lubrica- tion properties of regular mineral oil. The friction coefficient of nano-oil IV was found to be 0.02, which is the lowest friction coefficient among various nano-oils studied by Ref. [72]. Therefore, it can be stated that oil with more fullerene nanoparticle additives shows enhanced lubrication property [72], see Fig. 9 below. Fig. 10 shows the Stribeck curve measured for raw mineral oil, nano-oil I, II, III, and IV. It was noted that the friction coefficients of all oils were not appreciably changed up to the normal force of 200 N. However, when the normal force increased beyond 200 N, the viscosity was decreased by increasing oil temperature due to local metal-to-metal contact between the plates. One can see that the maximum friction coefficients were decreased as the fullerene volume fraction was increased. This is presumably attributed to (i) the added fullerene molecules accelerate self-restoration of the polymeric tribofilm damaged in the course of mechanochemical degradation, and also (ii) the fullerene particles with a spherical structure play a role of ball bearing in the friction surfaces [72]. Authors reported that the amount of scratched circles was FIG])(Fig._9[TD$decreased with increasing the volume concentration of the Fig. 9. Lubrication test results on the friction coefficient as a function of the fullerene volume fraction of nano-oil using the disk-on-disk type tester at the rotating speed of 1000 rpm [72].PDF Image | Renewable and Sustainable Energy Reviews

PDF Search Title:

Renewable and Sustainable Energy ReviewsOriginal File Name Searched:

A_review_on_the_performance_of_nanoparticles_suspended_with_refrigerants_and_lubricating_oils_in_ref.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |