PDF Publication Title:

Text from PDF Page: 052

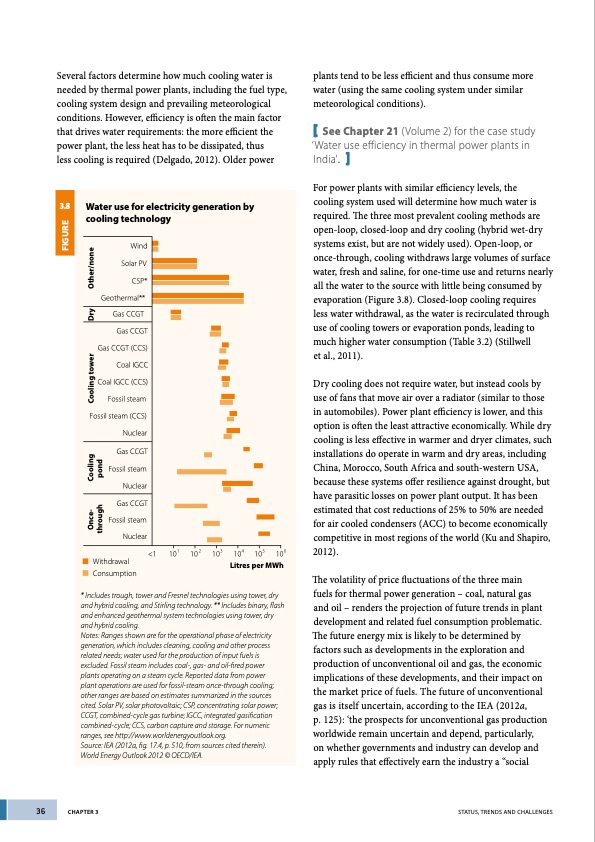

Several factors determine how much cooling water is needed by thermal power plants, including the fuel type, cooling system design and prevailing meteorological conditions. However, efficiency is often the main factor that drives water requirements: the more efficient the power plant, the less heat has to be dissipated, thus less cooling is required (Delgado, 2012). Older power plants tend to be less efficient and thus consume more water (using the same cooling system under similar meteorological conditions). [ See Chapter 21 (Volume 2) for the case study ‘Water use efficiency in thermal power plants in India’. ] For power plants with similar efficiency levels, the cooling system used will determine how much water is required. The three most prevalent cooling methods are open-loop, closed-loop and dry cooling (hybrid wet-dry systems exist, but are not widely used). Open-loop, or once-through, cooling withdraws large volumes of surface water, fresh and saline, for one-time use and returns nearly all the water to the source with little being consumed by evaporation (Figure 3.8). Closed-loop cooling requires less water withdrawal, as the water is recirculated through use of cooling towers or evaporation ponds, leading to much higher water consumption (Table 3.2) (Stillwell et al., 2011). Dry cooling does not require water, but instead cools by use of fans that move air over a radiator (similar to those in automobiles). Power plant efficiency is lower, and this option is often the least attractive economically. While dry cooling is less effective in warmer and dryer climates, such installations do operate in warm and dry areas, including China, Morocco, South Africa and south-western USA, because these systems offer resilience against drought, but have parasitic losses on power plant output. It has been estimated that cost reductions of 25% to 50% are needed for air cooled condensers (ACC) to become economically competitive in most regions of the world (Ku and Shapiro, 2012). The volatility of price fluctuations of the three main fuels for thermal power generation – coal, natural gas and oil – renders the projection of future trends in plant development and related fuel consumption problematic. The future energy mix is likely to be determined by factors such as developments in the exploration and production of unconventional oil and gas, the economic implications of these developments, and their impact on the market price of fuels. The future of unconventional gas is itself uncertain, according to the IEA (2012a, p. 125): ‘the prospects for unconventional gas production worldwide remain uncertain and depend, particularly, on whether governments and industry can develop and apply rules that effectively earn the industry a “social 3.8 Water use for electricity generation by cooling technology Wind Solar PV CSP* Geothermal** Gas CCGT Gas CCGT Gas CCGT (CCS) Coal IGCC Coal IGCC (CCS) Fossil steam Fossil steam (CCS) Nuclear Gas CCGT Fossil steam Nuclear Gas CCGT Fossil steam Nuclear Withdrawal Consumption <1 101 102 103 104 105 106 Litres per MWh * Includes trough, tower and Fresnel technologies using tower, dry and hybrid cooling, and Stirling technology. ** Includes binary, flash and enhanced geothermal system technologies using tower, dry and hybrid cooling. Notes: Ranges shown are for the operational phase of electricity generation, which includes cleaning, cooling and other process related needs; water used for the production of input fuels is excluded. Fossil steam includes coal-, gas- and oil-fired power plants operating on a steam cycle. Reported data from power plant operations are used for fossil-steam once-through cooling; other ranges are based on estimates summarized in the sources cited. Solar PV, solar photovoltaic; CSP, concentrating solar power; CCGT, combined-cycle gas turbine; IGCC, integrated gasification combined-cycle; CCS, carbon capture and storage. For numeric ranges, see http://www.worldenergyoutlook.org. Source: IEA (2012a, fig. 17.4, p. 510, from sources cited therein). World Energy Outlook 2012 © OECD/IEA. 36 CHAPTER 3 STATUS, TRENDS AND CHALLENGES Once- Cooling Cooling tower Dry Other/none through pond FIGUREPDF Image | Water and Energy

PDF Search Title:

Water and EnergyOriginal File Name Searched:

225741e.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |