PDF Publication Title:

Text from PDF Page: 045

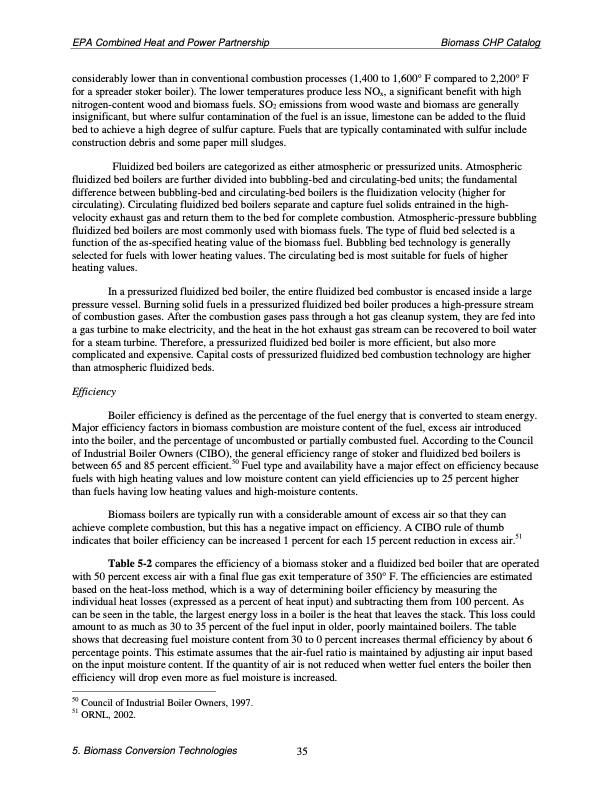

EPA Combined Heat and Power Partnership Biomass CHP Catalog considerably lower than in conventional combustion processes (1,400 to 1,600° F compared to 2,200° F for a spreader stoker boiler). The lower temperatures produce less NOx, a significant benefit with high nitrogen-content wood and biomass fuels. SO2 emissions from wood waste and biomass are generally insignificant, but where sulfur contamination of the fuel is an issue, limestone can be added to the fluid bed to achieve a high degree of sulfur capture. Fuels that are typically contaminated with sulfur include construction debris and some paper mill sludges. Fluidized bed boilers are categorized as either atmospheric or pressurized units. Atmospheric fluidized bed boilers are further divided into bubbling-bed and circulating-bed units; the fundamental difference between bubbling-bed and circulating-bed boilers is the fluidization velocity (higher for circulating). Circulating fluidized bed boilers separate and capture fuel solids entrained in the high- velocity exhaust gas and return them to the bed for complete combustion. Atmospheric-pressure bubbling fluidized bed boilers are most commonly used with biomass fuels. The type of fluid bed selected is a function of the as-specified heating value of the biomass fuel. Bubbling bed technology is generally selected for fuels with lower heating values. The circulating bed is most suitable for fuels of higher heating values. In a pressurized fluidized bed boiler, the entire fluidized bed combustor is encased inside a large pressure vessel. Burning solid fuels in a pressurized fluidized bed boiler produces a high-pressure stream of combustion gases. After the combustion gases pass through a hot gas cleanup system, they are fed into a gas turbine to make electricity, and the heat in the hot exhaust gas stream can be recovered to boil water for a steam turbine. Therefore, a pressurized fluidized bed boiler is more efficient, but also more complicated and expensive. Capital costs of pressurized fluidized bed combustion technology are higher than atmospheric fluidized beds. Efficiency Boiler efficiency is defined as the percentage of the fuel energy that is converted to steam energy. Major efficiency factors in biomass combustion are moisture content of the fuel, excess air introduced into the boiler, and the percentage of uncombusted or partially combusted fuel. According to the Council of Industrial Boiler Owners (CIBO), the general efficiency range of stoker and fluidized bed boilers is between 65 and 85 percent efficient.50 Fuel type and availability have a major effect on efficiency because fuels with high heating values and low moisture content can yield efficiencies up to 25 percent higher than fuels having low heating values and high-moisture contents. Biomass boilers are typically run with a considerable amount of excess air so that they can achieve complete combustion, but this has a negative impact on efficiency. A CIBO rule of thumb indicates that boiler efficiency can be increased 1 percent for each 15 percent reduction in excess air.51 Table 5-2 compares the efficiency of a biomass stoker and a fluidized bed boiler that are operated with 50 percent excess air with a final flue gas exit temperature of 350° F. The efficiencies are estimated based on the heat-loss method, which is a way of determining boiler efficiency by measuring the individual heat losses (expressed as a percent of heat input) and subtracting them from 100 percent. As can be seen in the table, the largest energy loss in a boiler is the heat that leaves the stack. This loss could amount to as much as 30 to 35 percent of the fuel input in older, poorly maintained boilers. The table shows that decreasing fuel moisture content from 30 to 0 percent increases thermal efficiency by about 6 percentage points. This estimate assumes that the air-fuel ratio is maintained by adjusting air input based on the input moisture content. If the quantity of air is not reduced when wetter fuel enters the boiler then efficiency will drop even more as fuel moisture is increased. 50 Council of Industrial Boiler Owners, 1997. 51 ORNL, 2002. 5. Biomass Conversion Technologies 35PDF Image | Biomass Combined Heat and Power Catalog of Technologies

PDF Search Title:

Biomass Combined Heat and Power Catalog of TechnologiesOriginal File Name Searched:

biomass_chp_catalog.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |