PDF Publication Title:

Text from PDF Page: 060

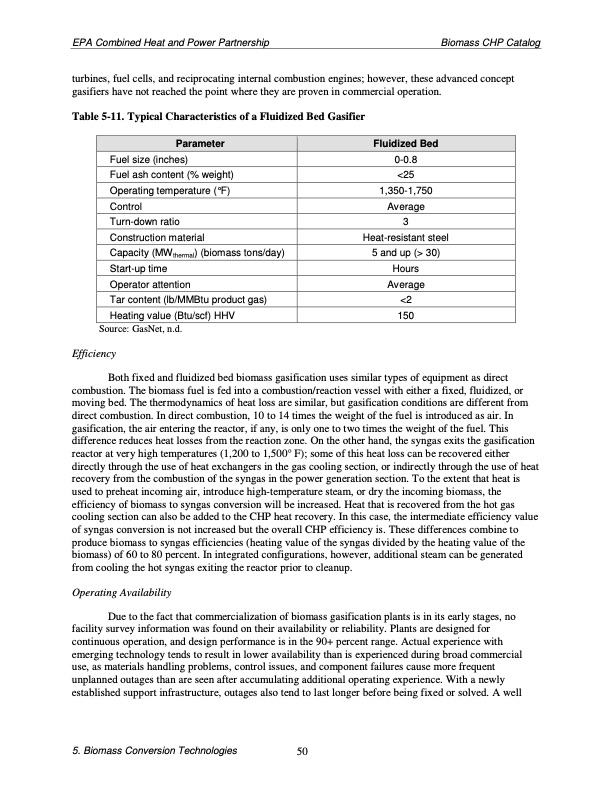

EPA Combined Heat and Power Partnership Biomass CHP Catalog turbines, fuel cells, and reciprocating internal combustion engines; however, these advanced concept gasifiers have not reached the point where they are proven in commercial operation. Table 5-11. Typical Characteristics of a Fluidized Bed Gasifier Parameter Fluidized Bed Fuel size (inches) Fuel ash content (% weight) Operating temperature (°F) Control Turn-down ratio Construction material Capacity (MWthermal) (biomass tons/day) Start-up time Operator attention Tar content (lb/MMBtu product gas) Heating value (Btu/scf) HHV Source: GasNet, n.d. Efficiency 0-0.8 <25 1,350-1,750 Average 3 Heat-resistant steel 5 and up (> 30) Hours Average <2 150 Both fixed and fluidized bed biomass gasification uses similar types of equipment as direct combustion. The biomass fuel is fed into a combustion/reaction vessel with either a fixed, fluidized, or moving bed. The thermodynamics of heat loss are similar, but gasification conditions are different from direct combustion. In direct combustion, 10 to 14 times the weight of the fuel is introduced as air. In gasification, the air entering the reactor, if any, is only one to two times the weight of the fuel. This difference reduces heat losses from the reaction zone. On the other hand, the syngas exits the gasification reactor at very high temperatures (1,200 to 1,500° F); some of this heat loss can be recovered either directly through the use of heat exchangers in the gas cooling section, or indirectly through the use of heat recovery from the combustion of the syngas in the power generation section. To the extent that heat is used to preheat incoming air, introduce high-temperature steam, or dry the incoming biomass, the efficiency of biomass to syngas conversion will be increased. Heat that is recovered from the hot gas cooling section can also be added to the CHP heat recovery. In this case, the intermediate efficiency value of syngas conversion is not increased but the overall CHP efficiency is. These differences combine to produce biomass to syngas efficiencies (heating value of the syngas divided by the heating value of the biomass) of 60 to 80 percent. In integrated configurations, however, additional steam can be generated from cooling the hot syngas exiting the reactor prior to cleanup. Operating Availability Due to the fact that commercialization of biomass gasification plants is in its early stages, no facility survey information was found on their availability or reliability. Plants are designed for continuous operation, and design performance is in the 90+ percent range. Actual experience with emerging technology tends to result in lower availability than is experienced during broad commercial use, as materials handling problems, control issues, and component failures cause more frequent unplanned outages than are seen after accumulating additional operating experience. With a newly established support infrastructure, outages also tend to last longer before being fixed or solved. A well 5. Biomass Conversion Technologies 50PDF Image | Biomass Combined Heat and Power Catalog of Technologies

PDF Search Title:

Biomass Combined Heat and Power Catalog of TechnologiesOriginal File Name Searched:

biomass_chp_catalog.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |