PDF Publication Title:

Text from PDF Page: 025

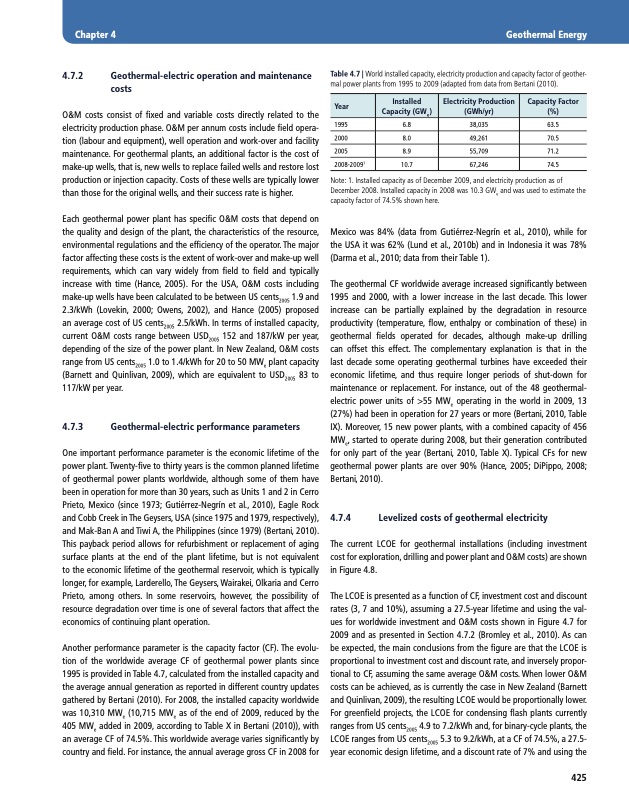

Chapter 4 Geothermal Energy 4.7.2 Geothermal-electric operation and maintenance costs O&M costs consist of fixed and variable costs directly related to the electricity production phase. O&M per annum costs include field opera- tion (labour and equipment), well operation and work-over and facility maintenance. For geothermal plants, an additional factor is the cost of make-up wells, that is, new wells to replace failed wells and restore lost production or injection capacity. Costs of these wells are typically lower than those for the original wells, and their success rate is higher. Each geothermal power plant has specific O&M costs that depend on the quality and design of the plant, the characteristics of the resource, environmental regulations and the efficiency of the operator. The major factor affecting these costs is the extent of work-over and make-up well requirements, which can vary widely from field to field and typically increase with time (Hance, 2005). For the USA, O&M costs including make-up wells have been calculated to be between US cents2005 1.9 and 2.3/kWh (Lovekin, 2000; Owens, 2002), and Hance (2005) proposed an average cost of US cents2005 2.5/kWh. In terms of installed capacity, current O&M costs range between USD2005 152 and 187/kW per year, depending of the size of the power plant. In New Zealand, O&M costs range from US cents2005 1.0 to 1.4/kWh for 20 to 50 MWe plant capacity (Barnett and Quinlivan, 2009), which are equivalent to USD2005 83 to 117/kW per year. 4.7.3 Geothermal-electric performance parameters One important performance parameter is the economic lifetime of the power plant. Twenty-five to thirty years is the common planned lifetime of geothermal power plants worldwide, although some of them have been in operation for more than 30 years, such as Units 1 and 2 in Cerro Prieto, Mexico (since 1973; Gutiérrez-Negrín et al., 2010), Eagle Rock and Cobb Creek in The Geysers, USA (since 1975 and 1979, respectively), and Mak-Ban A and Tiwi A, the Philippines (since 1979) (Bertani, 2010). This payback period allows for refurbishment or replacement of aging surface plants at the end of the plant lifetime, but is not equivalent to the economic lifetime of the geothermal reservoir, which is typically longer, for example, Larderello, The Geysers, Wairakei, Olkaria and Cerro Prieto, among others. In some reservoirs, however, the possibility of resource degradation over time is one of several factors that affect the economics of continuing plant operation. Another performance parameter is the capacity factor (CF). The evolu- tion of the worldwide average CF of geothermal power plants since 1995 is provided in Table 4.7, calculated from the installed capacity and the average annual generation as reported in different country updates gathered by Bertani (2010). For 2008, the installed capacity worldwide was 10,310 MWe (10,715 MWe as of the end of 2009, reduced by the 405 MWe added in 2009, according to Table X in Bertani (2010)), with an average CF of 74.5%. This worldwide average varies significantly by country and field. For instance, the annual average gross CF in 2008 for Table 4.7 | World installed capacity, electricity production and capacity factor of geother- mal power plants from 1995 to 2009 (adapted from data from Bertani (2010). 1995 63.5 2000 70.5 2005 71.2 2008-20091 74.5 Note: 1. Installed capacity as of December 2009, and electricity production as of December 2008. Installed capacity in 2008 was 10.3 GWe and was used to estimate the capacity factor of 74.5% shown here. Mexico was 84% (data from Gutiérrez-Negrín et al., 2010), while for the USA it was 62% (Lund et al., 2010b) and in Indonesia it was 78% (Darma et al., 2010; data from their Table 1). The geothermal CF worldwide average increased significantly between 1995 and 2000, with a lower increase in the last decade. This lower increase can be partially explained by the degradation in resource productivity (temperature, flow, enthalpy or combination of these) in geothermal fields operated for decades, although make-up drilling can offset this effect. The complementary explanation is that in the last decade some operating geothermal turbines have exceeded their economic lifetime, and thus require longer periods of shut-down for maintenance or replacement. For instance, out of the 48 geothermal- electric power units of >55 MWe operating in the world in 2009, 13 (27%) had been in operation for 27 years or more (Bertani, 2010, Table IX). Moreover, 15 new power plants, with a combined capacity of 456 MWe, started to operate during 2008, but their generation contributed for only part of the year (Bertani, 2010, Table X). Typical CFs for new geothermal power plants are over 90% (Hance, 2005; DiPippo, 2008; Bertani, 2010). 4.7.4 Levelized costs of geothermal electricity The current LCOE for geothermal installations (including investment cost for exploration, drilling and power plant and O&M costs) are shown in Figure 4.8. The LCOE is presented as a function of CF, investment cost and discount rates (3, 7 and 10%), assuming a 27.5-year lifetime and using the val- ues for worldwide investment and O&M costs shown in Figure 4.7 for 2009 and as presented in Section 4.7.2 (Bromley et al., 2010). As can be expected, the main conclusions from the figure are that the LCOE is proportional to investment cost and discount rate, and inversely propor- tional to CF, assuming the same average O&M costs. When lower O&M costs can be achieved, as is currently the case in New Zealand (Barnett and Quinlivan, 2009), the resulting LCOE would be proportionally lower. For greenfield projects, the LCOE for condensing flash plants currently ranges from US cents2005 4.9 to 7.2/kWh and, for binary-cycle plants, the LCOE ranges from US cents2005 5.3 to 9.2/kWh, at a CF of 74.5%, a 27.5- year economic design lifetime, and a discount rate of 7% and using the Year Installed Capacity (GWe ) Electricity Production (GWh/yr) Capacity Factor (%) 6.8 38,035 8.0 49,261 8.9 55,709 10.7 67,246 425PDF Image | Geothermal Energy 4

PDF Search Title:

Geothermal Energy 4Original File Name Searched:

Chapter_4_Geothermal_Energy_.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |