PDF Publication Title:

Text from PDF Page: 009

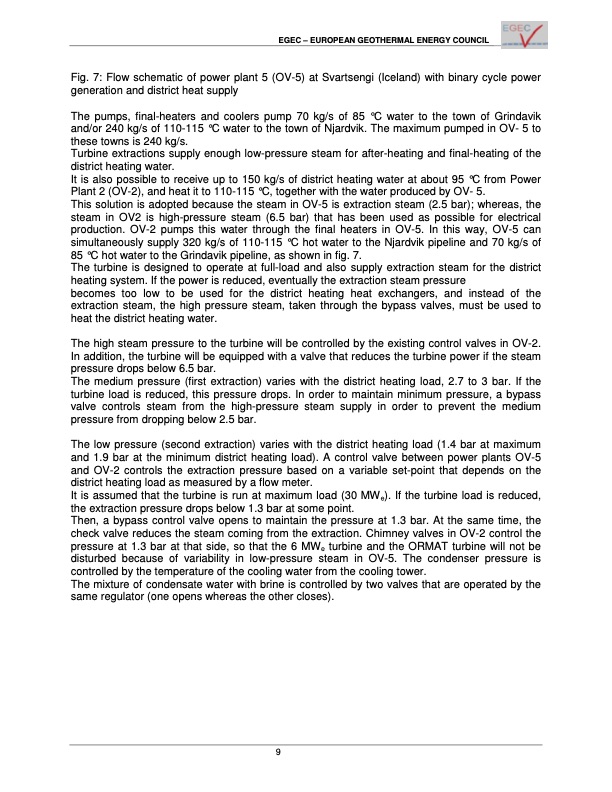

EGEC – EUROPEAN GEOTHERMAL ENERGY COUNCIL Fig. 7: Flow schematic of power plant 5 (OV-5) at Svartsengi (Iceland) with binary cycle power generation and district heat supply The pumps, final-heaters and coolers pump 70 kg/s of 85 °C water to the town of Grindavik and/or 240 kg/s of 110-115 °C water to the town of Njardvik. The maximum pumped in OV- 5 to these towns is 240 kg/s. Turbine extractions supply enough low-pressure steam for after-heating and final-heating of the district heating water. It is also possible to receive up to 150 kg/s of district heating water at about 95 °C from Power Plant 2 (OV-2), and heat it to 110-115 °C, together with the water produced by OV- 5. This solution is adopted because the steam in OV-5 is extraction steam (2.5 bar); whereas, the steam in OV2 is high-pressure steam (6.5 bar) that has been used as possible for electrical production. OV-2 pumps this water through the final heaters in OV-5. In this way, OV-5 can simultaneously supply 320 kg/s of 110-115 °C hot water to the Njardvik pipeline and 70 kg/s of 85 °C hot water to the Grindavik pipeline, as shown in fig. 7. The turbine is designed to operate at full-load and also supply extraction steam for the district heating system. If the power is reduced, eventually the extraction steam pressure becomes too low to be used for the district heating heat exchangers, and instead of the extraction steam, the high pressure steam, taken through the bypass valves, must be used to heat the district heating water. The high steam pressure to the turbine will be controlled by the existing control valves in OV-2. In addition, the turbine will be equipped with a valve that reduces the turbine power if the steam pressure drops below 6.5 bar. The medium pressure (first extraction) varies with the district heating load, 2.7 to 3 bar. If the turbine load is reduced, this pressure drops. In order to maintain minimum pressure, a bypass valve controls steam from the high-pressure steam supply in order to prevent the medium pressure from dropping below 2.5 bar. The low pressure (second extraction) varies with the district heating load (1.4 bar at maximum and 1.9 bar at the minimum district heating load). A control valve between power plants OV-5 and OV-2 controls the extraction pressure based on a variable set-point that depends on the district heating load as measured by a flow meter. It is assumed that the turbine is run at maximum load (30 MWe). If the turbine load is reduced, the extraction pressure drops below 1.3 bar at some point. Then, a bypass control valve opens to maintain the pressure at 1.3 bar. At the same time, the check valve reduces the steam coming from the extraction. Chimney valves in OV-2 control the pressure at 1.3 bar at that side, so that the 6 MWe turbine and the ORMAT turbine will not be disturbed because of variability in low-pressure steam in OV-5. The condenser pressure is controlled by the temperature of the cooling water from the cooling tower. The mixture of condensate water with brine is controlled by two valves that are operated by the same regulator (one opens whereas the other closes). 9PDF Image | COMBINED GEOTHERMAL HEAT AND POWER PLANTS CHP

PDF Search Title:

COMBINED GEOTHERMAL HEAT AND POWER PLANTS CHPOriginal File Name Searched:

D25_CHP_01.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |