PDF Publication Title:

Text from PDF Page: 005

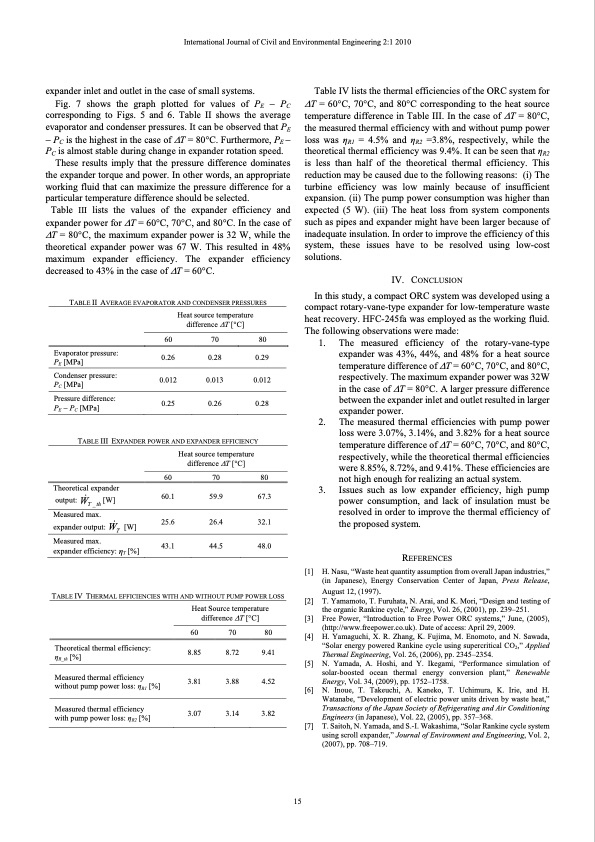

expander inlet and outlet in the case of small systems. Fig. 7 shows the graph plotted for values of PE − PC corresponding to Figs. 5 and 6. Table II shows the average evaporator and condenser pressures. It can be observed that PE − PC is the highest in the case of ΔT = 80°C. Furthermore, PE − PC is almost stable during change in expander rotation speed. These results imply that the pressure difference dominates the expander torque and power. In other words, an appropriate working fluid that can maximize the pressure difference for a particular temperature difference should be selected. Table III lists the values of the expander efficiency and expander power for ΔT = 60°C, 70°C, and 80°C. In the case of ΔT = 80°C, the maximum expander power is 32 W, while the theoretical expander power was 67 W. This resulted in 48% maximum expander efficiency. The expander efficiency decreased to 43% in the case of ΔT = 60°C. TABLE II AVERAGE EVAPORATOR AND CONDENSER PRESSURES Table IV lists the thermal efficiencies of the ORC system for ΔT = 60°C, 70°C, and 80°C corresponding to the heat source temperature difference in Table III. In the case of ΔT = 80°C, the measured thermal efficiency with and without pump power loss was ηR1 = 4.5% and ηR2 =3.8%, respectively, while the theoretical thermal efficiency was 9.4%. It can be seen that ηR2 is less than half of the theoretical thermal efficiency. This reduction may be caused due to the following reasons: (i) The turbine efficiency was low mainly because of insufficient expansion. (ii) The pump power consumption was higher than expected (5 W). (iii) The heat loss from system components such as pipes and expander might have been larger because of inadequate insulation. In order to improve the efficiency of this system, these issues have to be resolved using low-cost solutions. IV . CONCLUSION In this study, a compact ORC system was developed using a compact rotary-vane-type expander for low-temperature waste heat recovery. HFC-245fa was employed as the working fluid. The following observations were made: 1. The measured efficiency of the rotary-vane-type expander was 43%, 44%, and 48% for a heat source temperature difference of ΔT = 60°C, 70°C, and 80°C, respectively. The maximum expander power was 32W in the case of ΔT = 80°C. A larger pressure difference between the expander inlet and outlet resulted in larger expander power. 2. The measured thermal efficiencies with pump power loss were 3.07%, 3.14%, and 3.82% for a heat source temperature difference of ΔT = 60°C, 70°C, and 80°C, respectively, while the theoretical thermal efficiencies were 8.85%, 8.72%, and 9.41%. These efficiencies are not high enough for realizing an actual system. 3. Issues such as low expander efficiency, high pump power consumption, and lack of insulation must be resolved in order to improve the thermal efficiency of the proposed system. REFERENCES [1] H. Nasu, “Waste heat quantity assumption from overall Japan industries,” (in Japanese), Energy Conservation Center of Japan, Press Release, August 12, (1997). [2] T. Yamamoto, T. Furuhata, N. Arai, and K. Mori, “Design and testing of the organic Rankine cycle,” Energy, Vol. 26, (2001), pp. 239–251. [3] Free Power, “Introduction to Free Power ORC systems,” June, (2005), (http://www.freepower.co.uk). Date of access: April 29, 2009. [4] H. Yamaguchi, X. R. Zhang, K. Fujima, M. Enomoto, and N. Sawada, “Solar energy powered Rankine cycle using supercritical CO2,” Applied Thermal Engineering, Vol. 26, (2006), pp. 2345–2354. [5] N. Yamada, A. Hoshi, and Y. Ikegami, “Performance simulation of solar-boosted ocean thermal energy conversion plant,” Renewable Energy, V ol. 34, (2009), pp. 1752–1758. [6] N. Inoue, T. Takeuchi, A. Kaneko, T. Uchimura, K. Irie, and H. Watanabe, “Development of electric power units driven by waste heat,” Transactions of the Japan Society of Refrigerating and Air Conditioning Engineers (in Japanese), Vol. 22, (2005), pp. 357–368. [7] T. Saitoh, N. Yamada, and S.-I. Wakashima, “Solar Rankine cycle system using scroll expander,” Journal of Environment and Engineering, Vol. 2, (2007), pp. 708–719. Heat source temperature difference ΔT [°C] 60 70 80 TABLE III EXPANDER POWER AND EXPANDER EFFICIENCY Heat source temperature International Journal of Civil and Environmental Engineering 2:1 2010 Evaporator pressure: PE [MPa] Condenser pressure: PC [MPa] Pressure difference: PE − PC [MPa] 0.26 0.28 0.012 0.013 0.29 0.012 0.25 0.26 0.28 Theoretical expander Measured max. difference ΔT [°C] 60 70 80 60.1 59.9 67.3 � output: WT _ th [W] expander output: W�T [W] 25.6 26.4 32.1 43.1 44.5 48.0 Measured max. expander efficiency: ηT [%] TABLE IV THERMAL EFFICIENCIES WITH AND WITHOUT PUMP POWER LOSS Heat Source temperature Theoretical thermal efficiency: ηR_th [%] Measured thermal efficiency without pump power loss: ηR1 [%] Measured thermal efficiency with pump power loss: ηR2 [%] difference ΔT [°C] 60 70 80 8.85 8.72 9.41 3.81 3.88 3.07 3.14 4.52 3.82 15PDF Image | Efficiency of Compact Organic Rankine Cycle System with Rotary-Vane-Type Expander for Low-Temperature Waste Heat Recovery

PDF Search Title:

Efficiency of Compact Organic Rankine Cycle System with Rotary-Vane-Type Expander for Low-Temperature Waste Heat RecoveryOriginal File Name Searched:

Efficiency_of_Compact.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |