PDF Publication Title:

Text from PDF Page: 005

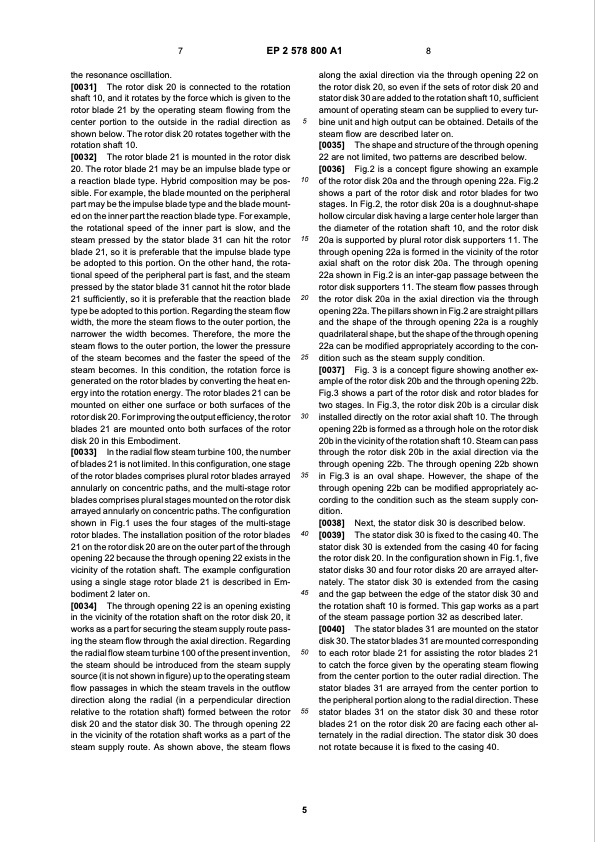

7 EP 2 578 800 A1 8 the resonance oscillation. [0031] The rotor disk 20 is connected to the rotation shaft 10, and it rotates by the force which is given to the rotor blade 21 by the operating steam flowing from the center portion to the outside in the radial direction as shown below. The rotor disk 20 rotates together with the rotation shaft 10. [0032] The rotor blade 21 is mounted in the rotor disk 20. The rotor blade 21 may be an impulse blade type or a reaction blade type. Hybrid composition may be pos- sible. For example, the blade mounted on the peripheral part may be the impulse blade type and the blade mount- ed on the inner part the reaction blade type. For example, the rotational speed of the inner part is slow, and the steam pressed by the stator blade 31 can hit the rotor blade 21, so it is preferable that the impulse blade type be adopted to this portion. On the other hand, the rota- tional speed of the peripheral part is fast, and the steam pressed by the stator blade 31 cannot hit the rotor blade 21 sufficiently, so it is preferable that the reaction blade type be adopted to this portion. Regarding the steam flow width, the more the steam flows to the outer portion, the narrower the width becomes. Therefore, the more the steam flows to the outer portion, the lower the pressure of the steam becomes and the faster the speed of the steam becomes. In this condition, the rotation force is generated on the rotor blades by converting the heat en- ergy into the rotation energy. The rotor blades 21 can be mounted on either one surface or both surfaces of the rotor disk 20. For improving the output efficiency, the rotor blades 21 are mounted onto both surfaces of the rotor disk 20 in this Embodiment. [0033] In the radial flow steam turbine 100, the number of blades 21 is not limited. In this configuration, one stage of the rotor blades comprises plural rotor blades arrayed annularly on concentric paths, and the multi-stage rotor blades comprises plural stages mounted on the rotor disk arrayed annularly on concentric paths. The configuration shown in Fig.1 uses the four stages of the multi-stage rotor blades. The installation position of the rotor blades 21 on the rotor disk 20 are on the outer part of the through opening 22 because the through opening 22 exists in the vicinity of the rotation shaft. The example configuration using a single stage rotor blade 21 is described in Em- bodiment 2 later on. [0034] The through opening 22 is an opening existing in the vicinity of the rotation shaft on the rotor disk 20, it works as a part for securing the steam supply route pass- ing the steam flow through the axial direction. Regarding the radial flow steam turbine 100 of the present invention, the steam should be introduced from the steam supply source (it is not shown in figure) up to the operating steam flow passages in which the steam travels in the outflow direction along the radial (in a perpendicular direction relative to the rotation shaft) formed between the rotor disk 20 and the stator disk 30. The through opening 22 in the vicinity of the rotation shaft works as a part of the steam supply route. As shown above, the steam flows along the axial direction via the through opening 22 on the rotor disk 20, so even if the sets of rotor disk 20 and stator disk 30 are added to the rotation shaft 10, sufficient amount of operating steam can be supplied to every tur- bine unit and high output can be obtained. Details of the steam flow are described later on. [0035] The shape and structure of the through opening 22 are not limited, two patterns are described below. [0036] Fig.2 is a concept figure showing an example of the rotor disk 20a and the through opening 22a. Fig.2 shows a part of the rotor disk and rotor blades for two stages. In Fig.2, the rotor disk 20a is a doughnut-shape hollow circular disk having a large center hole larger than the diameter of the rotation shaft 10, and the rotor disk 20a is supported by plural rotor disk supporters 11. The through opening 22a is formed in the vicinity of the rotor axial shaft on the rotor disk 20a. The through opening 22a shown in Fig.2 is an inter-gap passage between the rotor disk supporters 11. The steam flow passes through the rotor disk 20a in the axial direction via the through opening 22a. The pillars shown in Fig.2 are straight pillars and the shape of the through opening 22a is a roughly quadrilateral shape, but the shape of the through opening 22a can be modified appropriately according to the con- dition such as the steam supply condition. [0037] Fig. 3 is a concept figure showing another ex- ample of the rotor disk 20b and the through opening 22b. Fig.3 shows a part of the rotor disk and rotor blades for two stages. In Fig.3, the rotor disk 20b is a circular disk installed directly on the rotor axial shaft 10. The through opening 22b is formed as a through hole on the rotor disk 20b in the vicinity of the rotation shaft 10. Steam can pass through the rotor disk 20b in the axial direction via the through opening 22b. The through opening 22b shown in Fig.3 is an oval shape. However, the shape of the through opening 22b can be modified appropriately ac- cording to the condition such as the steam supply con- dition. [0038] Next, the stator disk 30 is described below. [0039] The stator disk 30 is fixed to the casing 40. The stator disk 30 is extended from the casing 40 for facing the rotor disk 20. In the configuration shown in Fig.1, five stator disks 30 and four rotor disks 20 are arrayed alter- nately. The stator disk 30 is extended from the casing and the gap between the edge of the stator disk 30 and the rotation shaft 10 is formed. This gap works as a part of the steam passage portion 32 as described later. [0040] The stator blades 31 are mounted on the stator disk 30. The stator blades 31 are mounted corresponding to each rotor blade 21 for assisting the rotor blades 21 to catch the force given by the operating steam flowing from the center portion to the outer radial direction. The stator blades 31 are arrayed from the center portion to the peripheral portion along to the radial direction. These stator blades 31 on the stator disk 30 and these rotor blades 21 on the rotor disk 20 are facing each other al- ternately in the radial direction. The stator disk 30 does not rotate because it is fixed to the casing 40. 5 10 15 20 25 30 35 40 45 50 55 5PDF Image | EP 2 578 800 A1 EUROPEAN PATENT

PDF Search Title:

EP 2 578 800 A1 EUROPEAN PATENTOriginal File Name Searched:

EP2578800A1.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |