PDF Publication Title:

Text from PDF Page: 006

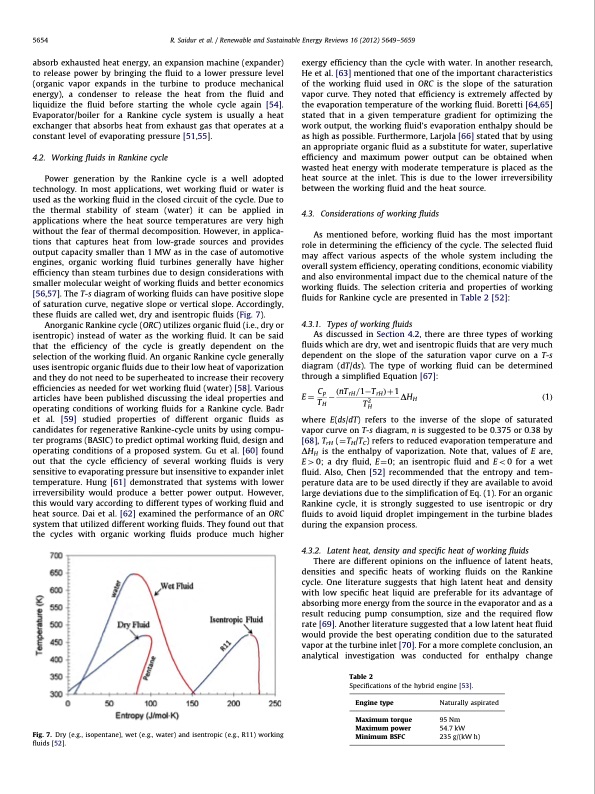

5654 R. Saidur et al. / Renewable and Sustainable Energy Reviews 16 (2012) 5649–5659 absorb exhausted heat energy, an expansion machine (expander) to release power by bringing the fluid to a lower pressure level (organic vapor expands in the turbine to produce mechanical energy), a condenser to release the heat from the fluid and liquidize the fluid before starting the whole cycle again [54]. Evaporator/boiler for a Rankine cycle system is usually a heat exchanger that absorbs heat from exhaust gas that operates at a constant level of evaporating pressure [51,55]. 4.2. Working fluids in Rankine cycle Power generation by the Rankine cycle is a well adopted technology. In most applications, wet working fluid or water is used as the working fluid in the closed circuit of the cycle. Due to the thermal stability of steam (water) it can be applied in applications where the heat source temperatures are very high without the fear of thermal decomposition. However, in applica- tions that captures heat from low-grade sources and provides output capacity smaller than 1 MW as in the case of automotive engines, organic working fluid turbines generally have higher efficiency than steam turbines due to design considerations with smaller molecular weight of working fluids and better economics [56,57]. The T-s diagram of working fluids can have positive slope of saturation curve, negative slope or vertical slope. Accordingly, these fluids are called wet, dry and isentropic fluids (Fig. 7). Anorganic Rankine cycle (ORC) utilizes organic fluid (i.e., dry or isentropic) instead of water as the working fluid. It can be said that the efficiency of the cycle is greatly dependent on the selection of the working fluid. An organic Rankine cycle generally uses isentropic organic fluids due to their low heat of vaporization and they do not need to be superheated to increase their recovery efficiencies as needed for wet working fluid (water) [58]. Various articles have been published discussing the ideal properties and operating conditions of working fluids for a Rankine cycle. Badr et al. [59] studied properties of different organic fluids as candidates for regenerative Rankine-cycle units by using compu- ter programs (BASIC) to predict optimal working fluid, design and operating conditions of a proposed system. Gu et al. [60] found out that the cycle efficiency of several working fluids is very sensitive to evaporating pressure but insensitive to expander inlet temperature. Hung [61] demonstrated that systems with lower irreversibility would produce a better power output. However, this would vary according to different types of working fluid and heat source. Dai et al. [62] examined the performance of an ORC system that utilized different working fluids. They found out that the cycles with organic working fluids produce much higher Fig. 7. Dry (e.g., isopentane), wet (e.g., water) and isentropic (e.g., R11) working fluids [52]. exergy efficiency than the cycle with water. In another research, He et al. [63] mentioned that one of the important characteristics of the working fluid used in ORC is the slope of the saturation vapor curve. They noted that efficiency is extremely affected by the evaporation temperature of the working fluid. Boretti [64,65] stated that in a given temperature gradient for optimizing the work output, the working fluid’s evaporation enthalpy should be as high as possible. Furthermore, Larjola [66] stated that by using an appropriate organic fluid as a substitute for water, superlative efficiency and maximum power output can be obtained when wasted heat energy with moderate temperature is placed as the heat source at the inlet. This is due to the lower irreversibility between the working fluid and the heat source. 4.3. Considerations of working fluids As mentioned before, working fluid has the most important role in determining the efficiency of the cycle. The selected fluid may affect various aspects of the whole system including the overall system efficiency, operating conditions, economic viability and also environmental impact due to the chemical nature of the working fluids. The selection criteria and properties of working fluids for Rankine cycle are presented in Table 2 [52]: 4.3.1. Types of working fluids As discussed in Section 4.2, there are three types of working fluids which are dry, wet and isentropic fluids that are very much dependent on the slope of the saturation vapor curve on a T-s diagram (dT/ds). The type of working fluid can be determined through a simplified Equation [67]: Cp ðnTrH=1TrHÞþ1 E1⁄4T 2 DHH ð1Þ H TH where E(ds/dT) refers to the inverse of the slope of saturated vapor curve on T-s diagram, n is suggested to be 0.375 or 0.38 by [68], TrH (1⁄4TH/TC) refers to reduced evaporation temperature and DHH is the enthalpy of vaporization. Note that, values of E are, E40; a dry fluid, E1⁄40; an isentropic fluid and Eo0 for a wet fluid. Also, Chen [52] recommended that the entropy and tem- perature data are to be used directly if they are available to avoid large deviations due to the simplification of Eq. (1). For an organic Rankine cycle, it is strongly suggested to use isentropic or dry fluids to avoid liquid droplet impingement in the turbine blades during the expansion process. 4.3.2. Latent heat, density and specific heat of working fluids There are different opinions on the influence of latent heats, densities and specific heats of working fluids on the Rankine cycle. One literature suggests that high latent heat and density with low specific heat liquid are preferable for its advantage of absorbing more energy from the source in the evaporator and as a result reducing pump consumption, size and the required flow rate [69]. Another literature suggested that a low latent heat fluid would provide the best operating condition due to the saturated vapor at the turbine inlet [70]. For a more complete conclusion, an analytical investigation was conducted for enthalpy change Table 2 Specifications of the hybrid engine [53]. Engine type Maximum torque Maximum power Minimum BSFC Naturally aspirated 95 Nm 54.7 kW 235 g/(kW h)PDF Image | Heat Condensing Operating Parameters ElectraTherm

PDF Search Title:

Heat Condensing Operating Parameters ElectraThermOriginal File Name Searched:

Dr.Saidur_Techn.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |