PDF Publication Title:

Text from PDF Page: 007

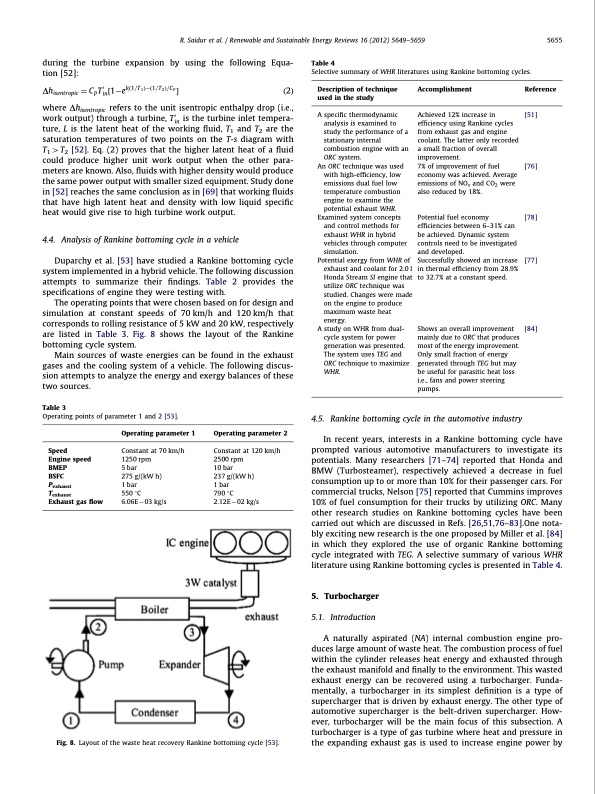

during the turbine expansion by using the following Equa- tion [52]: Dhisentropic 1⁄4 CpT0in1⁄21elðð1=T1Þð1=T2Þ=CP ð2Þ where Dhisentropic refers to the unit isentropic enthalpy drop (i.e., work output) through a turbine, T0in is the turbine inlet tempera- ture, L is the latent heat of the working fluid, T1 and T2 are the saturation temperatures of two points on the T-s diagram with T14T2 [52]. Eq. (2) proves that the higher latent heat of a fluid could produce higher unit work output when the other para- meters are known. Also, fluids with higher density would produce the same power output with smaller sized equipment. Study done in [52] reaches the same conclusion as in [69] that working fluids that have high latent heat and density with low liquid specific heat would give rise to high turbine work output. 4.4. Analysis of Rankine bottoming cycle in a vehicle Duparchy et al. [53] have studied a Rankine bottoming cycle system implemented in a hybrid vehicle. The following discussion attempts to summarize their findings. Table 2 provides the specifications of engine they were testing with. The operating points that were chosen based on for design and simulation at constant speeds of 70km/h and 120km/h that corresponds to rolling resistance of 5 kW and 20 kW, respectively are listed in Table 3. Fig. 8 shows the layout of the Rankine bottoming cycle system. Main sources of waste energies can be found in the exhaust gases and the cooling system of a vehicle. The following discus- sion attempts to analyze the energy and exergy balances of these two sources. Table 4 Selective summary of WHR literatures using Rankine bottoming cycles. Table 3 Operating points of parameter 1 and 2 [53]. Operating parameter 1 Operating parameter 2 Constant at 120 km/h 2500 rpm 10 bar 237 g/(kW h) 1 bar 790 1C 2.12E02 kg/s 4.5. Rankine bottoming cycle in the automotive industry In recent years, interests in a Rankine bottoming cycle have prompted various automotive manufacturers to investigate its potentials. Many researchers [71–74] reported that Honda and BMW (Turbosteamer), respectively achieved a decrease in fuel consumption up to or more than 10% for their passenger cars. For commercial trucks, Nelson [75] reported that Cummins improves 10% of fuel consumption for their trucks by utilizing ORC. Many other research studies on Rankine bottoming cycles have been carried out which are discussed in Refs. [26,51,76–83].One nota- bly exciting new research is the one proposed by Miller et al. [84] in which they explored the use of organic Rankine bottoming cycle integrated with TEG. A selective summary of various WHR literature using Rankine bottoming cycles is presented in Table 4. 5. Turbocharger 5.1. Introduction A naturally aspirated (NA) internal combustion engine pro- duces large amount of waste heat. The combustion process of fuel within the cylinder releases heat energy and exhausted through the exhaust manifold and finally to the environment. This wasted exhaust energy can be recovered using a turbocharger. Funda- mentally, a turbocharger in its simplest definition is a type of supercharger that is driven by exhaust energy. The other type of automotive supercharger is the belt-driven supercharger. How- ever, turbocharger will be the main focus of this subsection. A turbocharger is a type of gas turbine where heat and pressure in the expanding exhaust gas is used to increase engine power by R. Saidur et al. / Renewable and Sustainable Energy Reviews 16 (2012) 5649–5659 5655 Description of technique used in the study A specific thermodynamic analysis is examined to study the performance of a stationary internal combustion engine with an ORC system. An ORC technique was used with high-efficiency, low emissions dual fuel low temperature combustion engine to examine the potential exhaust WHR. Examined system concepts and control methods for exhaust WHR in hybrid vehicles through computer simulation. Potential exergy from WHR of exhaust and coolant for 2.0 l Honda Stream SI engine that utilize ORC technique was studied. Changes were made on the engine to produce maximum waste heat energy. A study on WHR from dual- cycle system for power generation was presented. The system uses TEG and ORC technique to maximize WHR. Accomplishment Reference Achieved 12% increase in [51] efficiency using Rankine cycles from exhaust gas and engine coolant. The latter only recorded a small fraction of overall improvement. 7% of improvement of fuel [76] economy was achieved. Average emissions of NOx and CO2 were also reduced by 18%. Potential fuel economy [78] efficiencies between 6–31% can be achieved. Dynamic system controls need to be investigated and developed. Successfully showed an increase [77] in thermal efficiency from 28.9% to 32.7% at a constant speed. Shows an overall improvement [84] mainly due to ORC that produces most of the energy improvement. Only small fraction of energy generated through TEG but may be useful for parasitic heat loss i.e., fans and power steering pumps. Speed Engine speed BMEP BSFC Pexhaust Texhaust Exhaust gas flow Constant at 70 km/h 1250 rpm 5 bar 275 g/(kW h) 1 bar 550 1C 6.06E03 kg/s Fig. 8. Layout of the waste heat recovery Rankine bottoming cycle [53].PDF Image | Heat Condensing Operating Parameters ElectraTherm

PDF Search Title:

Heat Condensing Operating Parameters ElectraThermOriginal File Name Searched:

Dr.Saidur_Techn.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |