PDF Publication Title:

Text from PDF Page: 006

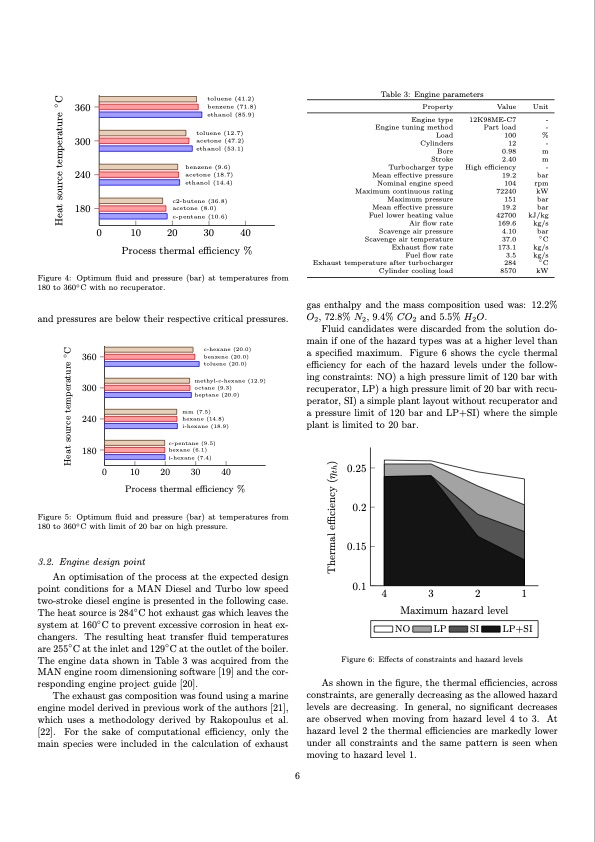

ayout the best fluids are not of the drytoltuyenpee(41e.2x)clusively, but instead wet (ethanol) 360 ne) while c2-butene is vaguely dry. This indicates that dry fluids are dependent on a benzene (9.6) acetone (18.7) ethanol (14.4) toluene (41.2) (3b6e.n8z)ene (71.8) 8.0) ethanol (85.9) c-pentane (10.6) Process thermal efficiency % 360 0.98 m nce of having benzene (71.8) ethanol (85.9) toluene (12.7) acetone (47.2) e superior efficie3n0c0y. However, the difference in net power between the best fluid and ethanol (53.1) lternatives is minor (5-8%). 240 360 180 300 240 Table 3: Engine parameters Property Engine type Engine tuning method Load Cylinders Bore Stroke Turbocharger type Mean effective pressure c2-butene acetone ( 0 10 20 toluene (12.7) Unit - - % - 30 40 acetone (47.2) ethanol (53.1) 12 Exhaust temperature after turbocharger 284 cale systems). The consequences of a 20 bar limit on the cycle are up to 2.5% lowCerylindeetr cooling load 8570 Figure 4: Optimum fluid and pressure (bar) at temperatures from C kW gest decreases are seen at higher source temperatures. All fluids are of the dry type, and entiontahnedipmrepssourrteasnacreobfelhowavtihnegirarersepdeuctcievdecbrioticlearlpreesssuurerse..DrOeF2si,cghu7re2e.r85%e:tONapl2t.i,m9[u4.4m]%mfluCeindOta2inoadnpdre5s.s5u%reH(b2aOr).attemperatures and cost concerns. Lai et al. [15] mention that the 20 bar limit has come from legal main if one of the hazard types was at a higher level than atl w their respective critical pressures. ◦ froFmlu1i8d0ctaon3d6i0daCtewsiwtherliemditisocfar2d0ebdarfronmhtighhepsroelsustuiroen. do- LP et hy l uids and up to 6% for the third best fluids compared to when the limit is 120 bar; see mm (7.5) hexane (14.8) a pressure limit of 120 bar and LP+SI) where the simple -c -he x an e (12 .9 ) 240 hexane (14.8) 180 Fuel flow rate 3.5 kg/s Air flow rate 169.6 kg/s Scavenge air pressure 4.10 bar recuperator, LP) a high pressure limit of 20 bar with recu- LP) a high pressure limit of 20 bar with recupera- perator, SI) a simple plant layout without recuperator and tor, SI) a simple plant layout without recuperator Value 12K98ME-C7 Part load 100 benzene (20.0) sure (bar) at temper 180 acetone (8.0) benzene (9.6) acetone (18.7) High efficiency - 19.2 bar ◦ methyl-c-hexane (12.9) :Optimumfluidandpresaturesfrom180to360Cwithnorecuperator.Nominalenginespeed104rpm c2-butene (36.8) ethanol (14.4) 300 octane (9.3) s mention the importa ety and cost concerns0. Lai et10al. [152]0mentio3n0that t4h0e 20 bar limit has come from legal i-hexane (18.9) Scavenge air temperature 37.0 ◦C Maximum continuous rating 72240 kW Maximum pressure 151 bar Mean effective pressure 19.2 bar a reduced boiler pressure. Drescher et al. [4] Fmuelnlotwioenr heating value 42700 kJ/kg c-pentane (10.6) mm (7.5) heptane (20.0) c-hexane (20.0) 2.40 m toluene (20.0) rtain countries. Kuo et al.P[r2o0c]easrsgtuheerfomraal eliffimcitieonfcy25%bar in order to keep material choexsatnse (6.1) c-pentane (9.5) Exhaust flow rate 173.1 kg/s i-hexane (7.4) ◦ 0 2 4 6 8 10 12 ptimumfluidandp◦ressure(bar)attemperaturesfrom180to360◦Cwithnorecuperator. t fluids a1n8d0 tuop36t0oC6%witfhonrotrheecutpheirradtorb.est fluids compared to when the limit is 120 bar; see Net power output MW gas enthalpy and the mass composition used was: 12.2% al. [20] argue for a in countries. Kuo et e systems). The consequences of a 20 b 300 c-hexane (20.0) a specified maximum. Figure 6 shows the cycle thermal benzene (20.0) tive tion and Wit mul 360 limit of 25 bar in order to keep material costs a toluene (20.0) efficiency for each of the hazard levels under the follow- r l i m octane (9.3) heptane (20.0) n t h m i t o hazard levels under the following constraints: NO) inaghciognhstprarienstsu:rNeOli)maithiogfh1p2r0essbuarre lwimitiht orfe1cu20pebraartworit,h e cycle are up to 2.5% lower net t higher sourc and a pressure limit of 120 bar and LP+SI) where tdecreasesarese2e4n0aetemperatures.Allfluidsareofthedrytype,and1, i-hexane (18.9) heir respective critical pressures. c-pentane (9.5) the simple plant is limited to 20 bar. 0.25 0.2 44 R 3ar tob cies flui ord out whe rec mis tob R imu the tain glo stro tha the (wi F sam sur eral 3.2. A erty for 180 360 300 hexane (6.1) i-hexane (7.4) 0 c-hexane (20.0) 30 benz4e0ne (20.0) 10 20 Process thermal efficiency % Figure 5: Optimum fluid and pressure (bar) at tem◦peratures from m fluid and pressure (bar) at temperatures from 180 to 360 C with limit of 20 bar on high pressure. 180 to 360◦C with limit of 20 bar on high pressure. mm (7.5) 240 3.2. Engine design point two-stroke die0sel eng1in0e is pr2e0sented3i0n the f4o0llowing case. The heat source is 284◦C hot exhaust gas which leaves the ◦ Process thermal efficiency % system at 160 C to prevent excessive corrosion in heat ex- NO LP SI LP+SI 10 no significant decreases are observed when moving [22]. For the sake of computational efficiency, only the main species were included in the calculation of exhaust 6 hazard level 2 the thermal efficiencies are markedly lower toluene (20.0) methyl-c-hexane (12.9) octane (9.3) heptane (20.0) hexane (14.8) i-hexane (18.9) 0.15 0.1 c-pentane (9.5) hexane (6.1) An op1t8i0misation of the process at the expected design i-hexane (7.4) plant is limited to 20 bar. point conditions for a MAN10Diesel and Turbo low speed 4321 Maximum hazard level changers. The resulting heat transfer fluid temperatures are 255◦C at the inlet and 129◦C at the outlet of◦ the boiler. fluid and pressure (bar) at temperatures from 180 to 360 C with limit of 20 bar on high pressure. The engine data shown in Table 3 was acquired from the MAN engine room dimensioning software [19] and the cor- responding engine project guide [20]. The exhaust gas composition was found using a marine engine model derived in previous work of the authors [21], which uses a methodology derived by Rakopoulus et al. Figure 6: Effects of constraints and hazard levels Figure 6: Effects of constraints and hazard levels As shoownnininthtehfiegfiugreu,rteh,eththeertmhearlmeffialcieffinccieies,ncaicerso,ss caoncrsotrsasinctosn, astrreagienntesr,aallryedgeecrneearsainllgyadsetchreealslionwgedashatzhaerd levels are decreasing. In general, no significant decreases allowed hazard levels are decreasing. In general, are observed when moving from hazard level 4 to 3. At from hazard level 4 to 3. At hazard level 2 the ther- under all constraints and the same pattern is seen when mal efficiencies are markedly lower under all con- moving to hazard level 1. straints and the same pattern is seen when moving to hazard level 1. Requiring a limited maximum pressure of 20 bar is seen to cause modestly reduced efficiencies com- pared to the SI constraint. At levels 4 and 3, the 7 o v a e m o a c e l a sw t u % e d e p u e m b t t o e . m Heat source temperature ◦C ◦ Heat source temperature C Heat source temperature ◦C ◦ Heat source temperature C Thermal efficiency (ηth) Heat source temperature ◦CPDF Image | organic Rankine cycles for waste heat recovery in marine settings

PDF Search Title:

organic Rankine cycles for waste heat recovery in marine settingsOriginal File Name Searched:

Design_and_optimisation_postPrint.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |