PDF Publication Title:

Text from PDF Page: 015

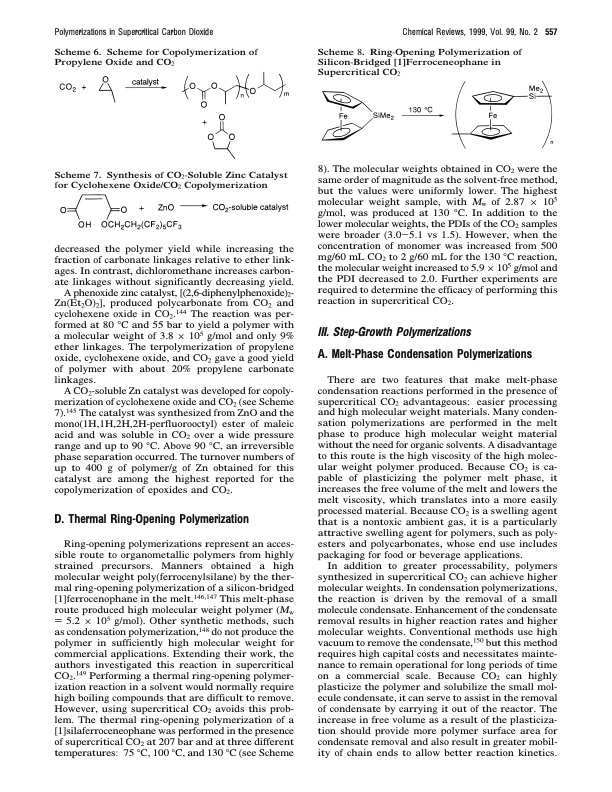

Polymerizations in Supercritical Carbon Dioxide Chemical Reviews, 1999, Vol. 99, No. 2 557 Scheme 6. Scheme for Copolymerization of Propylene Oxide and CO2 Scheme 7. Synthesis of CO2-Soluble Zinc Catalyst for Cyclohexene Oxide/CO2 Copolymerization decreased the polymer yield while increasing the fraction of carbonate linkages relative to ether link- ages. In contrast, dichloromethane increases carbon- ate linkages without significantly decreasing yield. A phenoxide zinc catalyst, [(2,6-diphenylphenoxide)2- Zn(Et2O)2], produced polycarbonate from CO2 and cyclohexene oxide in CO2.144 The reaction was per- formed at 80 °C and 55 bar to yield a polymer with a molecular weight of 3.8 × 105 g/mol and only 9% ether linkages. The terpolymerization of propylene oxide, cyclohexene oxide, and CO2 gave a good yield of polymer with about 20% propylene carbonate linkages. A CO2-soluble Zn catalyst was developed for copoly- merization of cyclohexene oxide and CO2 (see Scheme 7).145 The catalyst was synthesized from ZnO and the mono(1H,1H,2H,2H-perfluorooctyl) ester of maleic acid and was soluble in CO2 over a wide pressure range and up to 90 °C. Above 90 °C, an irreversible phase separation occurred. The turnover numbers of up to 400 g of polymer/g of Zn obtained for this catalyst are among the highest reported for the copolymerization of epoxides and CO2. D. Thermal Ring-Opening Polymerization Ring-opening polymerizations represent an acces- sible route to organometallic polymers from highly strained precursors. Manners obtained a high molecular weight poly(ferrocenylsilane) by the ther- mal ring-opening polymerization of a silicon-bridged [1]ferrocenophane in the melt.146,147 This melt-phase route produced high molecular weight polymer (Mw ) 5.2 × 105 g/mol). Other synthetic methods, such as condensation polymerization,148 do not produce the polymer in sufficiently high molecular weight for commercial applications. Extending their work, the authors investigated this reaction in supercritical CO2.149 Performing a thermal ring-opening polymer- ization reaction in a solvent would normally require high boiling compounds that are difficult to remove. However, using supercritical CO2 avoids this prob- lem. The thermal ring-opening polymerization of a [1]silaferroceneophane was performed in the presence of supercritical CO2 at 207 bar and at three different temperatures: 75 °C, 100 °C, and 130 °C (see Scheme Scheme 8. Ring-Opening Polymerization of Silicon-Bridged [1]Ferroceneophane in Supercritical CO2 8). The molecular weights obtained in CO2 were the same order of magnitude as the solvent-free method, but the values were uniformly lower. The highest molecular weight sample, with Mw of 2.87 × 105 g/mol, was produced at 130 °C. In addition to the lower molecular weights, the PDIs of the CO2 samples were broader (3.0-5.1 vs 1.5). However, when the concentration of monomer was increased from 500 mg/60 mL CO2 to 2 g/60 mL for the 130 °C reaction, the molecular weight increased to 5.9 × 105 g/mol and the PDI decreased to 2.0. Further experiments are required to determine the efficacy of performing this reaction in supercritical CO2. III. Step-Growth Polymerizations A. Melt-Phase Condensation Polymerizations There are two features that make melt-phase condensation reactions performed in the presence of supercritical CO2 advantageous: easier processing and high molecular weight materials. Many conden- sation polymerizations are performed in the melt phase to produce high molecular weight material without the need for organic solvents. A disadvantage to this route is the high viscosity of the high molec- ular weight polymer produced. Because CO2 is ca- pable of plasticizing the polymer melt phase, it increases the free volume of the melt and lowers the melt viscosity, which translates into a more easily processed material. Because CO2 is a swelling agent that is a nontoxic ambient gas, it is a particularly attractive swelling agent for polymers, such as poly- esters and polycarbonates, whose end use includes packaging for food or beverage applications. In addition to greater processability, polymers synthesized in supercritical CO2 can achieve higher molecular weights. In condensation polymerizations, the reaction is driven by the removal of a small molecule condensate. Enhancement of the condensate removal results in higher reaction rates and higher molecular weights. Conventional methods use high vacuum to remove the condensate,150 but this method requires high capital costs and necessitates mainte- nance to remain operational for long periods of time on a commercial scale. Because CO2 can highly plasticize the polymer and solubilize the small mol- ecule condensate, it can serve to assist in the removal of condensate by carrying it out of the reactor. The increase in free volume as a result of the plasticiza- tion should provide more polymer surface area for condensate removal and also result in greater mobil- ity of chain ends to allow better reaction kinetics.PDF Image | Polymerizations in Supercritical Carbon Dioxide

PDF Search Title:

Polymerizations in Supercritical Carbon DioxideOriginal File Name Searched:

desimonepolymerization.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |