PDF Publication Title:

Text from PDF Page: 019

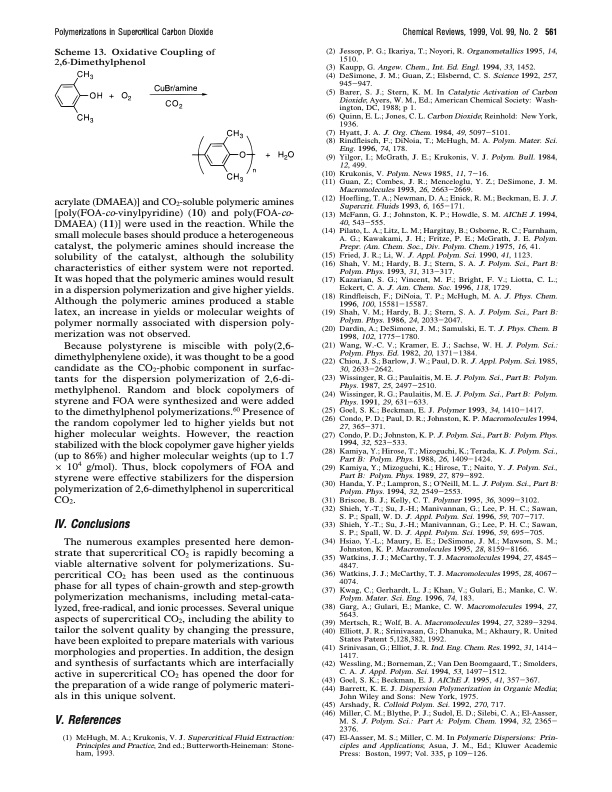

Polymerizations in Supercritical Carbon Dioxide Chemical Reviews, 1999, Vol. 99, No. 2 561 Scheme 13. Oxidative Coupling of 2,6-Dimethylphenol (2) Jessop, P. G.; Ikariya, T.; Noyori, R. Organometallics 1995, 14, 1510. (3) Kaupp, G. Angew. Chem., Int. Ed. Engl. 1994, 33, 1452. (4) DeSimone, J. M.; Guan, Z.; Elsbernd, C. S. Science 1992, 257, 945-947. (5) Barer, S. J.; Stern, K. M. In Catalytic Activation of Carbon Dioxide; Ayers, W. M., Ed.; American Chemical Society: Wash- ington, DC, 1988; p 1. (6) Quinn, E. L.; Jones, C. L. Carbon Dioxide; Reinhold: New York, 1936. (7) Hyatt, J. A. J. Org. Chem. 1984, 49, 5097-5101. (8) Rindfleisch, F.; DiNoia, T.; McHugh, M. A. Polym. Mater. Sci. Eng. 1996, 74, 178. (9) Yilgor, I.; McGrath, J. E.; Krukonis, V. J. Polym. Bull. 1984, 12, 499. (10) Krukonis, V. Polym. News 1985, 11, 7-16. (11) Guan, Z.; Combes, J. R.; Menceloglu, Y. Z.; DeSimone, J. M. Macromolecules 1993, 26, 2663-2669. (12) Hoefling, T. A.; Newman, D. A.; Enick, R. M.; Beckman, E. J. J. Supercrit. Fluids 1993, 6, 165-171. (13) McFann, G. J.; Johnston, K. P.; Howdle, S. M. AIChE J. 1994, 40, 543-555. (14) Pilato,L.A.;Litz,L.M.;Hargitay,B.;Osborne,R.C.;Farnham, A. G.; Kawakami, J. H.; Fritze, P. E.; McGrath, J. E. Polym. Prepr. (Am. Chem. Soc., Div. Polym. Chem.) 1975, 16, 41. (15) Fried, J. R.; Li, W. J. Appl. Polym. Sci. 1990, 41, 1123. (16) Shah, V. M.; Hardy, B. J.; Stern, S. A. J. Polym. Sci., Part B: Polym. Phys. 1993, 31, 313-317. (17) Kazarian, S. G.; Vincent, M. F.; Bright, F. V.; Liotta, C. L.; Eckert, C. A. J. Am. Chem. Soc. 1996, 118, 1729. (18) Rindfleisch, F.; DiNoia, T. P.; McHugh, M. A. J. Phys. Chem. 1996, 100, 15581-15587. (19) Shah, V. M.; Hardy, B. J.; Stern, S. A. J. Polym. Sci., Part B: Polym. Phys. 1986, 24, 2033-2047. (20) Dardin, A.; DeSimone, J. M.; Samulski, E. T. J. Phys. Chem. B 1998, 102, 1775-1780. (21) Wang, W.-C. V.; Kramer, E. J.; Sachse, W. H. J. Polym. Sci.: Polym. Phys. Ed. 1982, 20, 1371-1384. (22) Chiou,J.S.;Barlow,J.W.;Paul,D.R.J.Appl.Polym.Sci.1985, 30, 2633-2642. (23) Wissinger, R. G.; Paulaitis, M. E. J. Polym. Sci., Part B: Polym. Phys. 1987, 25, 2497-2510. (24) Wissinger, R. G.; Paulaitis, M. E. J. Polym. Sci., Part B: Polym. Phys. 1991, 29, 631-633. (25) Goel, S. K.; Beckman, E. J. Polymer 1993, 34, 1410-1417. (26) Condo,P.D.;Paul,D.R.;Johnston,K.P.Macromolecules1994, 27, 365-371. (27) Condo, P. D.; Johnston, K. P. J. Polym. Sci., Part B: Polym. Phys. 1994, 32, 523-533. (28) Kamiya,Y.;Hirose,T.;Mizoguchi,K.;Terada,K.J.Polym.Sci., Part B: Polym. Phys. 1988, 26, 1409-1424. (29) Kamiya, Y.; Mizoguchi, K.; Hirose, T.; Naito, Y. J. Polym. Sci., Part B: Polym. Phys. 1989, 27, 879-892. (30) Handa,Y.P.;Lampron,S.;O’Neill,M.L.J.Polym.Sci.,PartB: Polym. Phys. 1994, 32, 2549-2553. (31) Briscoe, B. J.; Kelly, C. T. Polymer 1995, 36, 3099-3102. (32) Shieh, Y.-T.; Su, J.-H.; Manivannan, G.; Lee, P. H. C.; Sawan, S. P.; Spall, W. D. J. Appl. Polym. Sci. 1996, 59, 707-717. (33) Shieh, Y.-T.; Su, J.-H.; Manivannan, G.; Lee, P. H. C.; Sawan, S. P.; Spall, W. D. J. Appl. Polym. Sci. 1996, 59, 695-705. (34) Hsiao, Y.-L.; Maury, E. E.; DeSimone, J. M.; Mawson, S. M.; Johnston, K. P. Macromolecules 1995, 28, 8159-8166. (35) Watkins,J.J.;McCarthy,T.J.Macromolecules1994,27,4845- 4847. (36) Watkins,J.J.;McCarthy,T.J.Macromolecules1995,28,4067- 4074. (37) Kwag, C.; Gerhardt, L. J.; Khan, V.; Gulari, E.; Manke, C. W. Polym. Mater. Sci. Eng. 1996, 74, 183. (38) Garg, A.; Gulari, E.; Manke, C. W. Macromolecules 1994, 27, 5643. (39) Mertsch, R.; Wolf, B. A. Macromolecules 1994, 27, 3289-3294. (40) Elliott, J. R.; Srinivasan, G.; Dhanuka, M.; Akhaury, R. United States Patent 5,128,382, 1992. (41) Srinivasan,G.;Elliot,J.R.Ind.Eng.Chem.Res.1992,31,1414- 1417. (42) Wessling, M.; Borneman, Z.; Van Den Boomgaard, T.; Smolders, C. A. J. Appl. Polym. Sci. 1994, 53, 1497-1512. (43) Goel, S. K.; Beckman, E. J. AIChE J. 1995, 41, 357-367. (44) Barrett, K. E. J. Dispersion Polymerization in Organic Media; John Wiley and Sons: New York, 1975. (45) Arshady, R. Colloid Polym. Sci. 1992, 270, 717. (46) Miller,C.M.;Blythe,P.J.;Sudol,E.D.;Silebi,C.A.;El-Aasser, M. S. J. Polym. Sci.: Part A: Polym. Chem. 1994, 32, 2365- 2376. (47) El-Aasser, M. S.; Miller, C. M. In Polymeric Dispersions: Prin- ciples and Applications; Asua, J. M., Ed.; Kluwer Academic Press: Boston, 1997; Vol. 335, p 109-126. acrylate (DMAEA)] and CO2-soluble polymeric amines [poly(FOA-co-vinylpyridine) (10) and poly(FOA-co- DMAEA) (11)] were used in the reaction. While the small molecule bases should produce a heterogeneous catalyst, the polymeric amines should increase the solubility of the catalyst, although the solubility characteristics of either system were not reported. It was hoped that the polymeric amines would result in a dispersion polymerization and give higher yields. Although the polymeric amines produced a stable latex, an increase in yields or molecular weights of polymer normally associated with dispersion poly- merization was not observed. Because polystyrene is miscible with poly(2,6- dimethylphenylene oxide), it was thought to be a good candidate as the CO2-phobic component in surfac- tants for the dispersion polymerization of 2,6-di- methylphenol. Random and block copolymers of styrene and FOA were synthesized and were added to the dimethylphenol polymerizations.60 Presence of the random copolymer led to higher yields but not higher molecular weights. However, the reaction stabilized with the block copolymer gave higher yields (up to 86%) and higher molecular weights (up to 1.7 × 104 g/mol). Thus, block copolymers of FOA and styrene were effective stabilizers for the dispersion polymerization of 2,6-dimethylphenol in supercritical CO2. IV. Conclusions The numerous examples presented here demon- strate that supercritical CO2 is rapidly becoming a viable alternative solvent for polymerizations. Su- percritical CO2 has been used as the continuous phase for all types of chain-growth and step-growth polymerization mechanisms, including metal-cata- lyzed, free-radical, and ionic processes. Several unique aspects of supercritical CO2, including the ability to tailor the solvent quality by changing the pressure, have been exploited to prepare materials with various morphologies and properties. In addition, the design and synthesis of surfactants which are interfacially active in supercritical CO2 has opened the door for the preparation of a wide range of polymeric materi- als in this unique solvent. V. References (1) McHugh, M. A.; Krukonis, V. J. Supercritical Fluid Extraction: Principles and Practice, 2nd ed.; Butterworth-Heineman: Stone- ham, 1993.PDF Image | Polymerizations in Supercritical Carbon Dioxide

PDF Search Title:

Polymerizations in Supercritical Carbon DioxideOriginal File Name Searched:

desimonepolymerization.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |