PDF Publication Title:

Text from PDF Page: 011

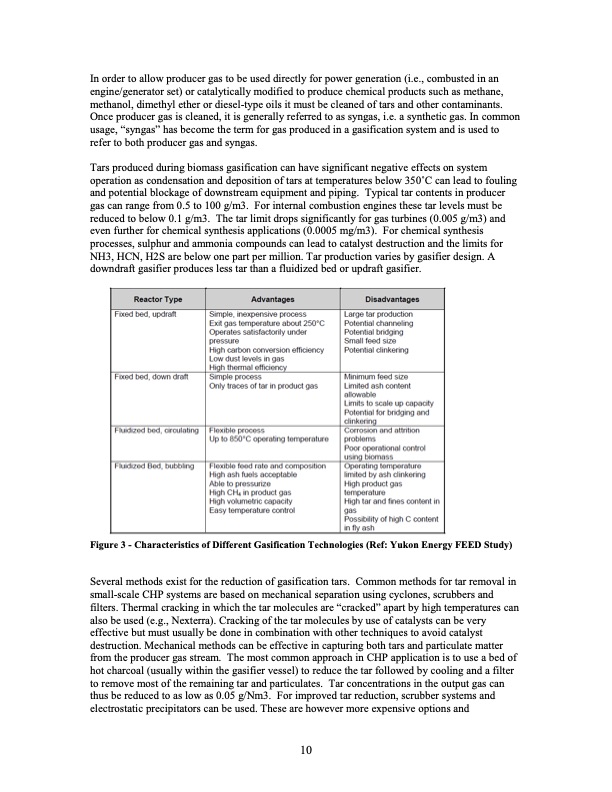

In order to allow producer gas to be used directly for power generation (i.e., combusted in an engine/generator set) or catalytically modified to produce chemical products such as methane, methanol, dimethyl ether or diesel-type oils it must be cleaned of tars and other contaminants. Once producer gas is cleaned, it is generally referred to as syngas, i.e. a synthetic gas. In common usage, “syngas” has become the term for gas produced in a gasification system and is used to refer to both producer gas and syngas. Tars produced during biomass gasification can have significant negative effects on system operation as condensation and deposition of tars at temperatures below 350 ̊C can lead to fouling and potential blockage of downstream equipment and piping. Typical tar contents in producer gas can range from 0.5 to 100 g/m3. For internal combustion engines these tar levels must be reduced to below 0.1 g/m3. The tar limit drops significantly for gas turbines (0.005 g/m3) and even further for chemical synthesis applications (0.0005 mg/m3). For chemical synthesis processes, sulphur and ammonia compounds can lead to catalyst destruction and the limits for NH3, HCN, H2S are below one part per million. Tar production varies by gasifier design. A downdraft gasifier produces less tar than a fluidized bed or updraft gasifier. Figure 3 - Characteristics of Different Gasification Technologies (Ref: Yukon Energy FEED Study) Several methods exist for the reduction of gasification tars. Common methods for tar removal in small-scale CHP systems are based on mechanical separation using cyclones, scrubbers and filters. Thermal cracking in which the tar molecules are “cracked” apart by high temperatures can also be used (e.g., Nexterra). Cracking of the tar molecules by use of catalysts can be very effective but must usually be done in combination with other techniques to avoid catalyst destruction. Mechanical methods can be effective in capturing both tars and particulate matter from the producer gas stream. The most common approach in CHP application is to use a bed of hot charcoal (usually within the gasifier vessel) to reduce the tar followed by cooling and a filter to remove most of the remaining tar and particulates. Tar concentrations in the output gas can thus be reduced to as low as 0.05 g/Nm3. For improved tar reduction, scrubber systems and electrostatic precipitators can be used. These are however more expensive options and 10PDF Image | Yukon Biomass Electrical Generation

PDF Search Title:

Yukon Biomass Electrical GenerationOriginal File Name Searched:

evaluation_of_commercially_available_small_scale_biomass2014.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |