PDF Publication Title:

Text from PDF Page: 006

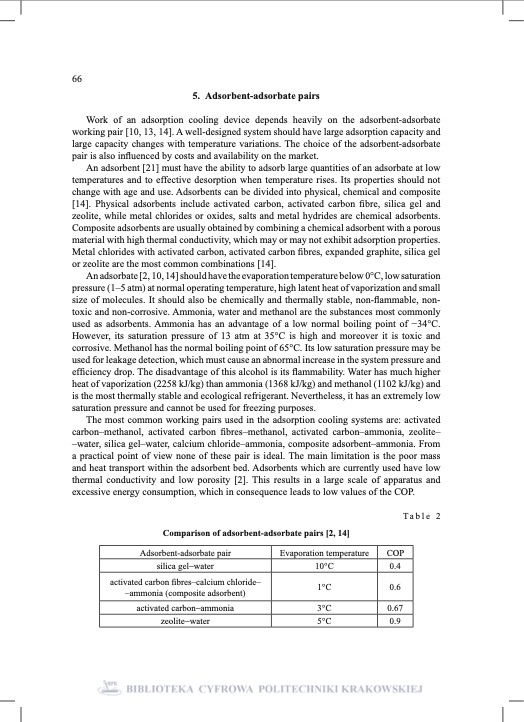

66 5. Adsorbent-adsorbate pairs Work of an adsorption cooling device depends heavily on the adsorbent-adsorbate working pair [10, 13, 14]. A well-designed system should have large adsorption capacity and large capacity changes with temperature variations. The choice of the adsorbent-adsorbate pair is also influenced by costs and availability on the market. An adsorbent [21] must have the ability to adsorb large quantities of an adsorbate at low temperatures and to effective desorption when temperature rises. Its properties should not change with age and use. Adsorbents can be divided into physical, chemical and composite [14]. Physical adsorbents include activated carbon, activated carbon fibre, silica gel and zeolite, while metal chlorides or oxides, salts and metal hydrides are chemical adsorbents. Composite adsorbents are usually obtained by combining a chemical adsorbent with a porous material with high thermal conductivity, which may or may not exhibit adsorption properties. Metal chlorides with activated carbon, activated carbon fibres, expanded graphite, silica gel or zeolite are the most common combinations [14]. An adsorbate [2, 10, 14] should have the evaporation temperature below 0°C, low saturation pressure (1–5 atm) at normal operating temperature, high latent heat of vaporization and small size of molecules. It should also be chemically and thermally stable, non-flammable, non- toxic and non-corrosive. Ammonia, water and methanol are the substances most commonly used as adsorbents. Ammonia has an advantage of a low normal boiling point of −34°C. However, its saturation pressure of 13 atm at 35°C is high and moreover it is toxic and corrosive. Methanol has the normal boiling point of 65°C. Its low saturation pressure may be used for leakage detection, which must cause an abnormal increase in the system pressure and efficiency drop. The disadvantage of this alcohol is its flammability. Water has much higher heat of vaporization (2258 kJ/kg) than ammonia (1368 kJ/kg) and methanol (1102 kJ/kg) and is the most thermally stable and ecological refrigerant. Nevertheless, it has an extremely low saturation pressure and cannot be used for freezing purposes. The most common working pairs used in the adsorption cooling systems are: activated carbon–methanol, activated carbon fibres–methanol, activated carbon–ammonia, zeolite– –water, silica gel–water, calcium chloride–ammonia, composite adsorbent–ammonia. From a practical point of view none of these pair is ideal. The main limitation is the poor mass and heat transport within the adsorbent bed. Adsorbents which are currently used have low thermal conductivity and low porosity [2]. This results in a large scale of apparatus and excessive energy consumption, which in consequence leads to low values of the COP. Comparison of adsorbent-adsorbate pairs [2, 14] Table 2 Adsorbent-adsorbate pair silica gel-water activated carbon fibres–calcium chloride– –ammonia (composite adsorbent) activated carbon-ammonia zeolite-water Evaporation temperature COP 10°C 0.4 1°C 0.6 3°C 0.67 5°C 0.9PDF Image | ADSORPTION COOLING AS WASTE HEAT UTILIZATION

PDF Search Title:

ADSORPTION COOLING AS WASTE HEAT UTILIZATIONOriginal File Name Searched:

GwaderaM_AdsorptionCooling.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |