PDF Publication Title:

Text from PDF Page: 009

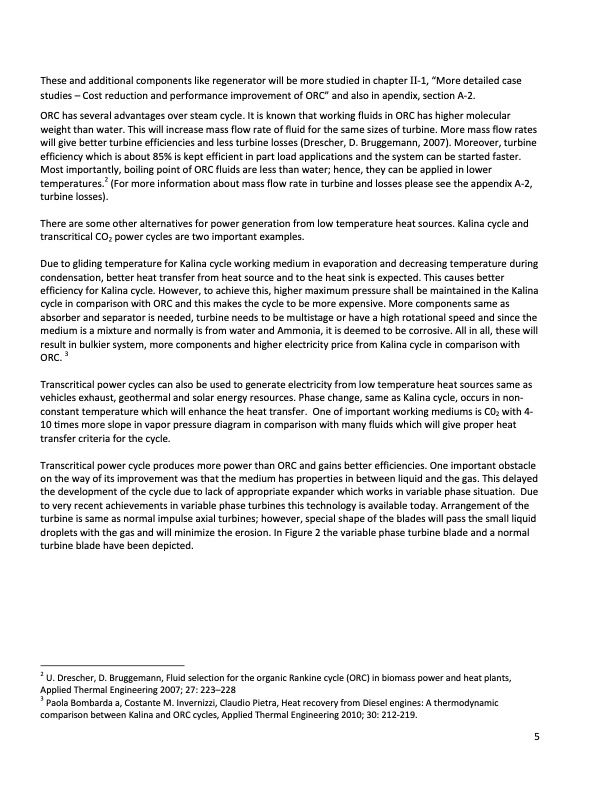

These and additional components like regenerator will be more studied in chapter ΙΙ‐1, “More detailed case studies – Cost reduction and performance improvement of ORC” and also in apendix, section A‐2. ORC has several advantages over steam cycle. It is known that working fluids in ORC has higher molecular weight than water. This will increase mass flow rate of fluid for the same sizes of turbine. More mass flow rates will give better turbine efficiencies and less turbine losses (Drescher, D. Bruggemann, 2007). Moreover, turbine efficiency which is about 85% is kept efficient in part load applications and the system can be started faster. Most importantly, boiling point of ORC fluids are less than water; hence, they can be applied in lower temperatures.2 (For more information about mass flow rate in turbine and losses please see the appendix A‐2, turbine losses). There are some other alternatives for power generation from low temperature heat sources. Kalina cycle and transcritical CO2 power cycles are two important examples. Due to gliding temperature for Kalina cycle working medium in evaporation and decreasing temperature during condensation, better heat transfer from heat source and to the heat sink is expected. This causes better efficiency for Kalina cycle. However, to achieve this, higher maximum pressure shall be maintained in the Kalina cycle in comparison with ORC and this makes the cycle to be more expensive. More components same as absorber and separator is needed, turbine needs to be multistage or have a high rotational speed and since the medium is a mixture and normally is from water and Ammonia, it is deemed to be corrosive. All in all, these will result in bulkier system, more components and higher electricity price from Kalina cycle in comparison with ORC. 3 Transcritical power cycles can also be used to generate electricity from low temperature heat sources same as vehicles exhaust, geothermal and solar energy resources. Phase change, same as Kalina cycle, occurs in non‐ constant temperature which will enhance the heat transfer. One of important working mediums is C02 with 4‐ 10 times more slope in vapor pressure diagram in comparison with many fluids which will give proper heat transfer criteria for the cycle. Transcritical power cycle produces more power than ORC and gains better efficiencies. One important obstacle on the way of its improvement was that the medium has properties in between liquid and the gas. This delayed the development of the cycle due to lack of appropriate expander which works in variable phase situation. Due to very recent achievements in variable phase turbines this technology is available today. Arrangement of the turbine is same as normal impulse axial turbines; however, special shape of the blades will pass the small liquid droplets with the gas and will minimize the erosion. In Figure 2 the variable phase turbine blade and a normal turbine blade have been depicted. 2 U. Drescher, D. Bruggemann, Fluid selection for the organic Rankine cycle (ORC) in biomass power and heat plants, Applied Thermal Engineering 2007; 27: 223–228 3 Paola Bombarda a, Costante M. Invernizzi, Claudio Pietra, Heat recovery from Diesel engines: A thermodynamic comparison between Kalina and ORC cycles, Applied Thermal Engineering 2010; 30: 212‐219. 5PDF Image | Exergy

PDF Search Title:

ExergyOriginal File Name Searched:

orc-evaluation.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |