PDF Publication Title:

Text from PDF Page: 007

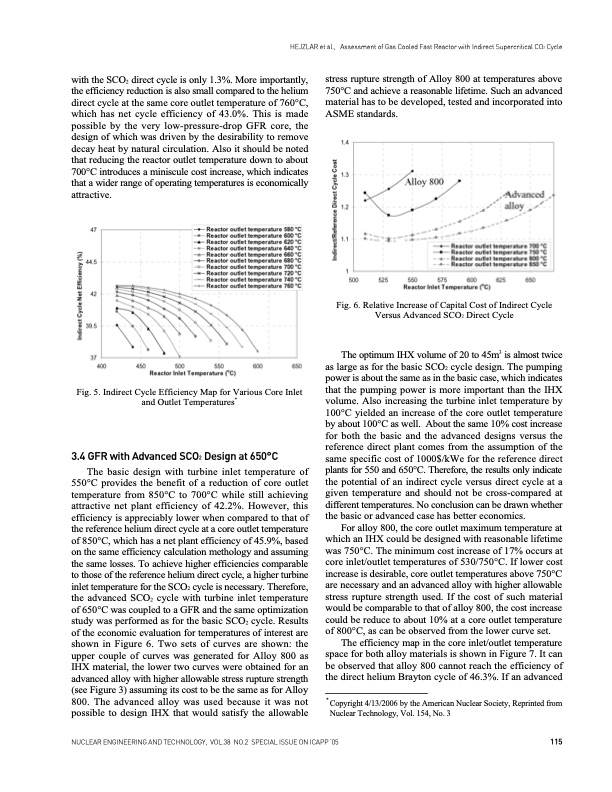

with the SCO2 direct cycle is only 1.3%. More importantly, the efficiency reduction is also small compared to the helium direct cycle at the same core outlet temperature of 760°C, which has net cycle efficiency of 43.0%. This is made possible by the very low-pressure-drop GFR core, the design of which was driven by the desirability to remove decay heat by natural circulation. Also it should be noted that reducing the reactor outlet temperature down to about 700°C introduces a miniscule cost increase, which indicates that a wider range of operating temperatures is economically attractive. 3.4 GFR with Advanced SCO2 Design at 650°C The basic design with turbine inlet temperature of 550°C provides the benefit of a reduction of core outlet temperature from 850°C to 700°C while still achieving attractive net plant efficiency of 42.2%. However, this efficiency is appreciably lower when compared to that of the reference helium direct cycle at a core outlet temperature of 850°C, which has a net plant efficiency of 45.9%, based on the same efficiency calculation methology and assuming the same losses. To achieve higher efficiencies comparable to those of the reference helium direct cycle, a higher turbine inlet temperature for the SCO2 cycle is necessary. Therefore, the advanced SCO2 cycle with turbine inlet temperature of 650°C was coupled to a GFR and the same optimization study was performed as for the basic SCO2 cycle. Results of the economic evaluation for temperatures of interest are shown in Figure 6. Two sets of curves are shown: the upper couple of curves was generated for Alloy 800 as IHX material, the lower two curves were obtained for an advanced alloy with higher allowable stress rupture strength (see Figure 3) assuming its cost to be the same as for Alloy 800. The advanced alloy was used because it was not possible to design IHX that would satisfy the allowable stress rupture strength of Alloy 800 at temperatures above 750°C and achieve a reasonable lifetime. Such an advanced material has to be developed, tested and incorporated into ASME standards. The optimum IHX volume of 20 to 45m3 is almost twice as large as for the basic SCO2 cycle design. The pumping power is about the same as in the basic case, which indicates that the pumping power is more important than the IHX volume. Also increasing the turbine inlet temperature by 100°C yielded an increase of the core outlet temperature by about 100°C as well. About the same 10% cost increase for both the basic and the advanced designs versus the reference direct plant comes from the assumption of the same specific cost of 1000$/kWe for the reference direct plants for 550 and 650°C. Therefore, the results only indicate the potential of an indirect cycle versus direct cycle at a given temperature and should not be cross-compared at different temperatures. No conclusion can be drawn whether the basic or advanced case has better economics. For alloy 800, the core outlet maximum temperature at which an IHX could be designed with reasonable lifetime was 750°C. The minimum cost increase of 17% occurs at core inlet/outlet temperatures of 530/750°C. If lower cost increase is desirable, core outlet temperatures above 750°C are necessary and an advanced alloy with higher allowable stress rupture strength used. If the cost of such material would be comparable to that of alloy 800, the cost increase could be reduce to about 10% at a core outlet temperature of 800°C, as can be observed from the lower curve set. The efficiency map in the core inlet/outlet temperature space for both alloy materials is shown in Figure 7. It can be observed that alloy 800 cannot reach the efficiency of the direct helium Brayton cycle of 46.3%. If an advanced HEJZLARetal., AssessmentofGasCooledFastReactorwithIndirectSupercriticalCO2Cycle Fig. 5. Indirect Cycle Efficiency Map for Various Core Inlet and Outlet Temperatures* Fig. 6. Relative Increase of Capital Cost of Indirect Cycle Versus Advanced SCO2 Direct Cycle * Copyright 4/13/2006 by the American Nuclear Society, Reprinted from Nuclear Technology, Vol. 154, No. 3 NUCLEAR ENGINEERING AND TECHNOLOGY, VOL.38 NO.2 SPECIAL ISSUE ON ICAPP ‘05 115PDF Image | GAS COOLED FAST REACTOR WITH INDIRECT SUPERCRITICAL CO2

PDF Search Title:

GAS COOLED FAST REACTOR WITH INDIRECT SUPERCRITICAL CO2Original File Name Searched:

Infinity_JK0380109.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |