PDF Publication Title:

Text from PDF Page: 004

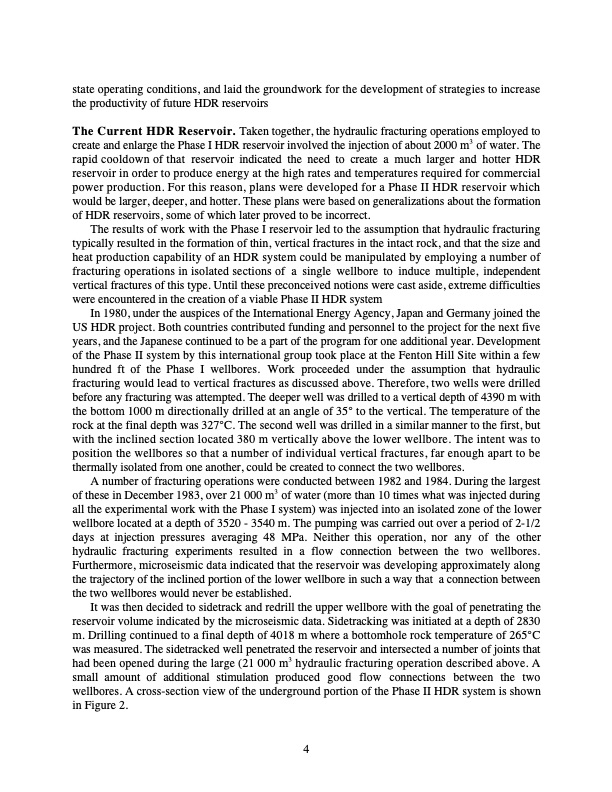

state operating conditions, and laid the groundwork for the development of strategies to increase the productivity of future HDR reservoirs The Current HDR Reservoir. Taken together, the hydraulic fracturing operations employed to create and enlarge the Phase I HDR reservoir involved the injection of about 2000 m3 of water. The rapid cooldown of that reservoir indicated the need to create a much larger and hotter HDR reservoir in order to produce energy at the high rates and temperatures required for commercial power production. For this reason, plans were developed for a Phase II HDR reservoir which would be larger, deeper, and hotter. These plans were based on generalizations about the formation of HDR reservoirs, some of which later proved to be incorrect. The results of work with the Phase I reservoir led to the assumption that hydraulic fracturing typically resulted in the formation of thin, vertical fractures in the intact rock, and that the size and heat production capability of an HDR system could be manipulated by employing a number of fracturing operations in isolated sections of a single wellbore to induce multiple, independent vertical fractures of this type. Until these preconceived notions were cast aside, extreme difficulties were encountered in the creation of a viable Phase II HDR system In 1980, under the auspices of the International Energy Agency, Japan and Germany joined the US HDR project. Both countries contributed funding and personnel to the project for the next five years, and the Japanese continued to be a part of the program for one additional year. Development of the Phase II system by this international group took place at the Fenton Hill Site within a few hundred ft of the Phase I wellbores. Work proceeded under the assumption that hydraulic fracturing would lead to vertical fractures as discussed above. Therefore, two wells were drilled before any fracturing was attempted. The deeper well was drilled to a vertical depth of 4390 m with the bottom 1000 m directionally drilled at an angle of 35° to the vertical. The temperature of the rock at the final depth was 327°C. The second well was drilled in a similar manner to the first, but with the inclined section located 380 m vertically above the lower wellbore. The intent was to position the wellbores so that a number of individual vertical fractures, far enough apart to be thermally isolated from one another, could be created to connect the two wellbores. A number of fracturing operations were conducted between 1982 and 1984. During the largest of these in December 1983, over 21 000 m3 of water (more than 10 times what was injected during all the experimental work with the Phase I system) was injected into an isolated zone of the lower wellbore located at a depth of 3520 - 3540 m. The pumping was carried out over a period of 2-1/2 days at injection pressures averaging 48 MPa. Neither this operation, nor any of the other hydraulic fracturing experiments resulted in a flow connection between the two wellbores. Furthermore, microseismic data indicated that the reservoir was developing approximately along the trajectory of the inclined portion of the lower wellbore in such a way that a connection between the two wellbores would never be established. It was then decided to sidetrack and redrill the upper wellbore with the goal of penetrating the reservoir volume indicated by the microseismic data. Sidetracking was initiated at a depth of 2830 m. Drilling continued to a final depth of 4018 m where a bottomhole rock temperature of 265°C was measured. The sidetracked well penetrated the reservoir and intersected a number of joints that had been opened during the large (21 000 m3 hydraulic fracturing operation described above. A small amount of additional stimulation produced good flow connections between the two wellbores. A cross-section view of the underground portion of the Phase II HDR system is shown in Figure 2. 4PDF Image | Hot Dry Rock Geothermal Energy Development in the USA

PDF Search Title:

Hot Dry Rock Geothermal Energy Development in the USAOriginal File Name Searched:

HDRintheUS.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |