PDF Publication Title:

Text from PDF Page: 007

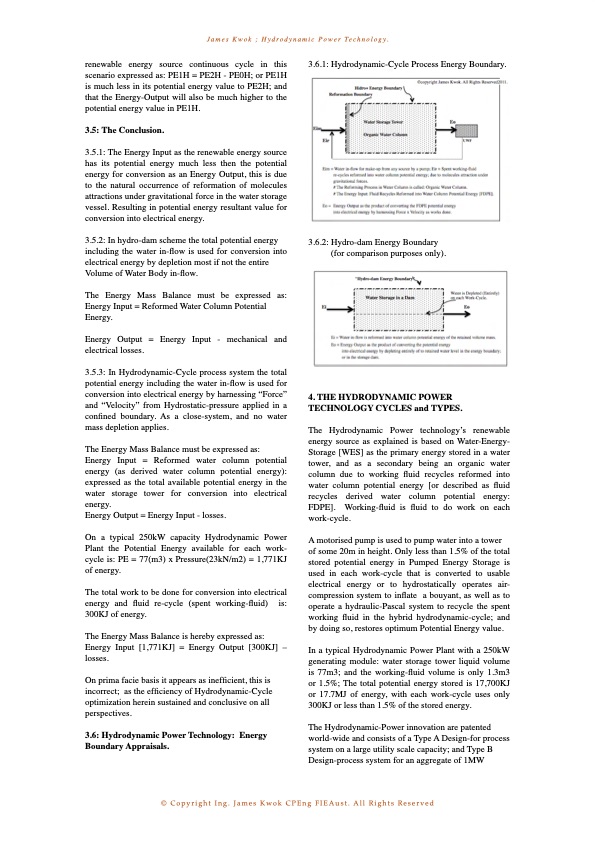

renewable energy source continuous cycle in this scenario expressed as: PE1H = PE2H - PE0H; or PE1H is much less in its potential energy value to PE2H; and that the Energy-Output will also be much higher to the potential energy value in PE1H. 3.5: The Conclusion. 3.5.1: The Energy Input as the renewable energy source has its potential energy much less then the potential energy for conversion as an Energy Output, this is due to the natural occurrence of reformation of molecules attractions under gravitational force in the water storage vessel. Resulting in potential energy resultant value for conversion into electrical energy. 3.5.2: In hydro-dam scheme the total potential energy including the water in-flow is used for conversion into electrical energy by depletion most if not the entire Volume of Water Body in-flow. The Energy Mass Balance must be expressed as: Energy Input = Reformed Water Column Potential Energy. Energy Output = Energy Input - mechanical and electrical losses. 3.5.3: In Hydrodynamic-Cycle process system the total potential energy including the water in-flow is used for conversion into electrical energy by harnessing “Force” and “Velocity” from Hydrostatic-pressure applied in a confined boundary. As a close-system, and no water mass depletion applies. The Energy Mass Balance must be expressed as: Energy Input = Reformed water column potential energy (as derived water column potential energy): expressed as the total available potential energy in the water storage tower for conversion into electrical energy. Energy Output = Energy Input - losses. On a typical 250kW capacity Hydrodynamic Power Plant the Potential Energy available for each work- cycle is: PE = 77(m3) x Pressure(23kN/m2) = 1,771KJ of energy. The total work to be done for conversion into electrical energy and fluid re-cycle (spent working-fluid) is: 300KJ of energy. The Energy Mass Balance is hereby expressed as: Energy Input [1,771KJ] = Energy Output [300KJ] – losses. On prima facie basis it appears as inefficient, this is incorrect; as the efficiency of Hydrodynamic-Cycle optimization herein sustained and conclusive on all perspectives. 3.6: Hydrodynamic Power Technology: Energy Boundary Appraisals. 3.6.1: Hydrodynamic-Cycle Process Energy Boundary. 3.6.2: Hydro-dam Energy Boundary (for comparison purposes only). 4. THE HYDRODYNAMIC POWER TECHNOLOGY CYCLES and TYPES. The Hydrodynamic Power technology’s renewable energy source as explained is based on Water-Energy- Storage [WES] as the primary energy stored in a water tower, and as a secondary being an organic water column due to working fluid recycles reformed into water column potential energy [or described as fluid recycles derived water column potential energy: FDPE]. Working-fluid is fluid to do work on each work-cycle. A motorised pump is used to pump water into a tower of some 20m in height. Only less than 1.5% of the total stored potential energy in Pumped Energy Storage is used in each work-cycle that is converted to usable electrical energy or to hydrostatically operates air- compression system to inflate a bouyant, as well as to operate a hydraulic-Pascal system to recycle the spent working fluid in the hybrid hydrodynamic-cycle; and by doing so, restores optimum Potential Energy value. In a typical Hydrodynamic Power Plant with a 250kW generating module: water storage tower liquid volume is 77m3; and the working-fluid volume is only 1.3m3 or 1.5%; The total potential energy stored is 17,700KJ or 17.7MJ of energy, with each work-cycle uses only 300KJ or less than 1.5% of the stored energy. The Hydrodynamic-Power innovation are patented world-wide and consists of a Type A Design-for process system on a large utility scale capacity; and Type B Design-process system for an aggregate of 1MW James Kwok ; Hydrodynamic Power Technology. © Copyright Ing. James Kwok CPEng FIEAust. All Rights ReservedPDF Image | HYDRODYNAMIC POWER TECHNOLOGY

PDF Search Title:

HYDRODYNAMIC POWER TECHNOLOGYOriginal File Name Searched:

hydrodynamic_power_technology_paper.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |