PDF Publication Title:

Text from PDF Page: 008

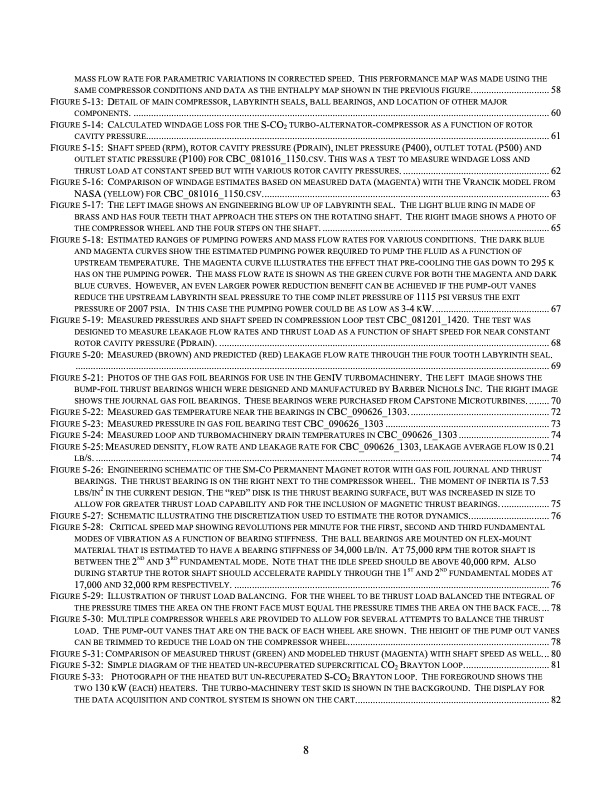

MASS FLOW RATE FOR PARAMETRIC VARIATIONS IN CORRECTED SPEED. THIS PERFORMANCE MAP WAS MADE USING THE SAME COMPRESSOR CONDITIONS AND DATA AS THE ENTHALPY MAP SHOWN IN THE PREVIOUS FIGURE............................... 58 FIGURE 5-13: DETAIL OF MAIN COMPRESSOR, LABYRINTH SEALS, BALL BEARINGS, AND LOCATION OF OTHER MAJOR COMPONENTS. ..................................................................................................................................................................... 60 FIGURE 5-14: CALCULATED WINDAGE LOSS FOR THE S-CO2 TURBO-ALTERNATOR-COMPRESSOR AS A FUNCTION OF ROTOR CAVITY PRESSURE................................................................................................................................................................ 61 FIGURE 5-15: SHAFT SPEED (RPM), ROTOR CAVITY PRESSURE (PDRAIN), INLET PRESSURE (P400), OUTLET TOTAL (P500) AND OUTLET STATIC PRESSURE (P100) FOR CBC_081016_1150.CSV. THIS WAS A TEST TO MEASURE WINDAGE LOSS AND THRUST LOAD AT CONSTANT SPEED BUT WITH VARIOUS ROTOR CAVITY PRESSURES. .......................................................... 62 FIGURE 5-16: COMPARISON OF WINDAGE ESTIMATES BASED ON MEASURED DATA (MAGENTA) WITH THE VRANCIK MODEL FROM NASA (YELLOW) FOR CBC_081016_1150.CSV.................................................................................................................. 63 FIGURE 5-17: THE LEFT IMAGE SHOWS AN ENGINEERING BLOW UP OF LABYRINTH SEAL. THE LIGHT BLUE RING IN MADE OF BRASS AND HAS FOUR TEETH THAT APPROACH THE STEPS ON THE ROTATING SHAFT. THE RIGHT IMAGE SHOWS A PHOTO OF THE COMPRESSOR WHEEL AND THE FOUR STEPS ON THE SHAFT. .......................................................................................... 65 FIGURE 5-18: ESTIMATED RANGES OF PUMPING POWERS AND MASS FLOW RATES FOR VARIOUS CONDITIONS. THE DARK BLUE AND MAGENTA CURVES SHOW THE ESTIMATED PUMPING POWER REQUIRED TO PUMP THE FLUID AS A FUNCTION OF UPSTREAM TEMPERATURE. THE MAGENTA CURVE ILLUSTRATES THE EFFECT THAT PRE-COOLING THE GAS DOWN TO 295 K HAS ON THE PUMPING POWER. THE MASS FLOW RATE IS SHOWN AS THE GREEN CURVE FOR BOTH THE MAGENTA AND DARK BLUE CURVES. HOWEVER, AN EVEN LARGER POWER REDUCTION BENEFIT CAN BE ACHIEVED IF THE PUMP-OUT VANES REDUCE THE UPSTREAM LABYRINTH SEAL PRESSURE TO THE COMP INLET PRESSURE OF 1115 PSI VERSUS THE EXIT PRESSUREOF2007PSIA. INTHISCASETHEPUMPINGPOWERCOULDBEASLOWAS3-4KW..............................................67 FIGURE 5-19: MEASURED PRESSURES AND SHAFT SPEED IN COMPRESSION LOOP TEST CBC_081201_1420. THE TEST WAS DESIGNED TO MEASURE LEAKAGE FLOW RATES AND THRUST LOAD AS A FUNCTION OF SHAFT SPEED FOR NEAR CONSTANT ROTOR CAVITY PRESSURE (PDRAIN). ................................................................................................................................... 68 FIGURE 5-20: MEASURED (BROWN) AND PREDICTED (RED) LEAKAGE FLOW RATE THROUGH THE FOUR TOOTH LABYRINTH SEAL. ............................................................................................................................................................................................ 69 FIGURE 5-21: PHOTOS OF THE GAS FOIL BEARINGS FOR USE IN THE GENIV TURBOMACHINERY. THE LEFT IMAGE SHOWS THE BUMP-FOIL THRUST BEARINGS WHICH WERE DESIGNED AND MANUFACTURED BY BARBER NICHOLS INC. THE RIGHT IMAGE SHOWS THE JOURNAL GAS FOIL BEARINGS. THESE BEARINGS WERE PURCHASED FROM CAPSTONE MICROTURBINES. ........ 70 FIGURE 5-22: MEASURED GAS TEMPERATURE NEAR THE BEARINGS IN CBC_090626_1303........................................................ 72 FIGURE 5-23: MEASURED PRESSURE IN GAS FOIL BEARING TEST CBC_090626_1303 ................................................................. 73 FIGURE 5-24: MEASURED LOOP AND TURBOMACHINERY DRAIN TEMPERATURES IN CBC_090626_1303 .................................... 74 FIGURE 5-25: MEASURED DENSITY, FLOW RATE AND LEAKAGE RATE FOR CBC_090626_1303, LEAKAGE AVERAGE FLOW IS 0.21 LB/S. .................................................................................................................................................................................... 74 FIGURE 5-26: ENGINEERING SCHEMATIC OF THE SM-CO PERMANENT MAGNET ROTOR WITH GAS FOIL JOURNAL AND THRUST BEARINGS. THE THRUST BEARING IS ON THE RIGHT NEXT TO THE COMPRESSOR WHEEL. THE MOMENT OF INERTIA IS 7.53 LBS/IN2 IN THE CURRENT DESIGN. THE “RED” DISK IS THE THRUST BEARING SURFACE, BUT WAS INCREASED IN SIZE TO ALLOW FOR GREATER THRUST LOAD CAPABILITY AND FOR THE INCLUSION OF MAGNETIC THRUST BEARINGS. ................... 75 FIGURE 5-27: SCHEMATIC ILLUSTRATING THE DISCRETIZATION USED TO ESTIMATE THE ROTOR DYNAMICS................................ 76 FIGURE5-28: CRITICALSPEEDMAPSHOWINGREVOLUTIONSPERMINUTEFORTHEFIRST,SECONDANDTHIRDFUNDAMENTAL MODES OF VIBRATION AS A FUNCTION OF BEARING STIFFNESS. THE BALL BEARINGS ARE MOUNTED ON FLEX-MOUNT MATERIAL THAT IS ESTIMATED TO HAVE A BEARING STIFFNESS OF 34,000 LB/IN. AT 75,000 RPM THE ROTOR SHAFT IS BETWEEN THE 2ND AND 3RD FUNDAMENTAL MODE. NOTE THAT THE IDLE SPEED SHOULD BE ABOVE 40,000 RPM. ALSO DURING STARTUP THE ROTOR SHAFT SHOULD ACCELERATE RAPIDLY THROUGH THE 1ST AND 2ND FUNDAMENTAL MODES AT 17,000 AND 32,000 RPM RESPECTIVELY. ............................................................................................................................. 76 FIGURE 5-29: ILLUSTRATION OF THRUST LOAD BALANCING. FOR THE WHEEL TO BE THRUST LOAD BALANCED THE INTEGRAL OF THE PRESSURE TIMES THE AREA ON THE FRONT FACE MUST EQUAL THE PRESSURE TIMES THE AREA ON THE BACK FACE. ... 78 FIGURE 5-30: MULTIPLE COMPRESSOR WHEELS ARE PROVIDED TO ALLOW FOR SEVERAL ATTEMPTS TO BALANCE THE THRUST LOAD. THE PUMP-OUT VANES THAT ARE ON THE BACK OF EACH WHEEL ARE SHOWN. THE HEIGHT OF THE PUMP OUT VANES CAN BE TRIMMED TO REDUCE THE LOAD ON THE COMPRESSOR WHEEL................................................................................ 78 FIGURE 5-31: COMPARISON OF MEASURED THRUST (GREEN) AND MODELED THRUST (MAGENTA) WITH SHAFT SPEED AS WELL... 80 FIGURE 5-32: SIMPLE DIAGRAM OF THE HEATED UN-RECUPERATED SUPERCRITICAL CO2 BRAYTON LOOP.................................. 81 FIGURE 5-33: PHOTOGRAPH OF THE HEATED BUT UN-RECUPERATED S-CO2 BRAYTON LOOP. THE FOREGROUND SHOWS THE TWO 130 KW (EACH) HEATERS. THE TURBO-MACHINERY TEST SKID IS SHOWN IN THE BACKGROUND. THE DISPLAY FOR THE DATA ACQUISITION AND CONTROL SYSTEM IS SHOWN ON THE CART............................................................................. 82 8PDF Image | Operation and Analysis of a Supercritical CO2 Brayton Cycle

PDF Search Title:

Operation and Analysis of a Supercritical CO2 Brayton CycleOriginal File Name Searched:

Infinity_100171.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |