PDF Publication Title:

Text from PDF Page: 006

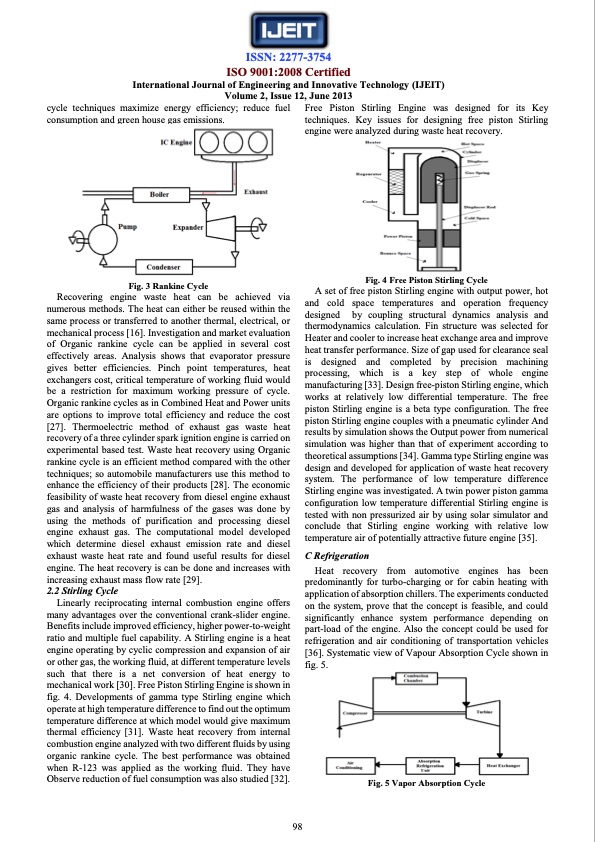

ISSN: 2277-3754 ISO 9001:2008 Certified International Journal of Engineering and Innovative Technology (IJEIT) Volume 2, Issue 12, June 2013 cycle techniques maximize energy efficiency; reduce fuel consumption and green house gas emissions. Fig. 3 Rankine Cycle Recovering engine waste heat can be achieved via numerous methods. The heat can either be reused within the same process or transferred to another thermal, electrical, or mechanical process [16]. Investigation and market evaluation of Organic rankine cycle can be applied in several cost effectively areas. Analysis shows that evaporator pressure gives better efficiencies. Pinch point temperatures, heat exchangers cost, critical temperature of working fluid would be a restriction for maximum working pressure of cycle. Organic rankine cycles as in Combined Heat and Power units are options to improve total efficiency and reduce the cost [27]. Thermoelectric method of exhaust gas waste heat recovery of a three cylinder spark ignition engine is carried on experimental based test. Waste heat recovery using Organic rankine cycle is an efficient method compared with the other techniques; so automobile manufacturers use this method to enhance the efficiency of their products [28]. The economic feasibility of waste heat recovery from diesel engine exhaust gas and analysis of harmfulness of the gases was done by using the methods of purification and processing diesel engine exhaust gas. The computational model developed which determine diesel exhaust emission rate and diesel exhaust waste heat rate and found useful results for diesel engine. The heat recovery is can be done and increases with increasing exhaust mass flow rate [29]. 2.2 Stirling Cycle Linearly reciprocating internal combustion engine offers many advantages over the conventional crank-slider engine. Benefits include improved efficiency, higher power-to-weight ratio and multiple fuel capability. A Stirling engine is a heat engine operating by cyclic compression and expansion of air or other gas, the working fluid, at different temperature levels such that there is a net conversion of heat energy to mechanical work [30]. Free Piston Stirling Engine is shown in fig. 4. Developments of gamma type Stirling engine which operate at high temperature difference to find out the optimum temperature difference at which model would give maximum thermal efficiency [31]. Waste heat recovery from internal combustion engine analyzed with two different fluids by using organic rankine cycle. The best performance was obtained when R-123 was applied as the working fluid. They have Observe reduction of fuel consumption was also studied [32]. Free Piston Stirling Engine was designed for its Key techniques. Key issues for designing free piston Stirling engine were analyzed during waste heat recovery. Fig. 4 Free Piston Stirling Cycle A set of free piston Stirling engine with output power, hot and cold space temperatures and operation frequency designed by coupling structural dynamics analysis and thermodynamics calculation. Fin structure was selected for Heater and cooler to increase heat exchange area and improve heat transfer performance. Size of gap used for clearance seal is designed and completed by precision machining processing, which is a key step of whole engine manufacturing [33]. Design free-piston Stirling engine, which works at relatively low differential temperature. The free piston Stirling engine is a beta type configuration. The free piston Stirling engine couples with a pneumatic cylinder And results by simulation shows the Output power from numerical simulation was higher than that of experiment according to theoretical assumptions [34]. Gamma type Stirling engine was design and developed for application of waste heat recovery system. The performance of low temperature difference Stirling engine was investigated. A twin power piston gamma configuration low temperature differential Stirling engine is tested with non pressurized air by using solar simulator and conclude that Stirling engine working with relative low temperature air of potentially attractive future engine [35]. C Refrigeration Heat recovery from automotive engines has been predominantly for turbo-charging or for cabin heating with application of absorption chillers. The experiments conducted on the system, prove that the concept is feasible, and could significantly enhance system performance depending on part-load of the engine. Also the concept could be used for refrigeration and air conditioning of transportation vehicles [36]. Systematic view of Vapour Absorption Cycle shown in fig. 5. Fig. 5 Vapor Absorption Cycle 98PDF Image | Review on Exhaust Gas Heat Recovery for I.C. Engine

PDF Search Title:

Review on Exhaust Gas Heat Recovery for I.C. EngineOriginal File Name Searched:

IJEIT1412201306_18.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |