PDF Publication Title:

Text from PDF Page: 016

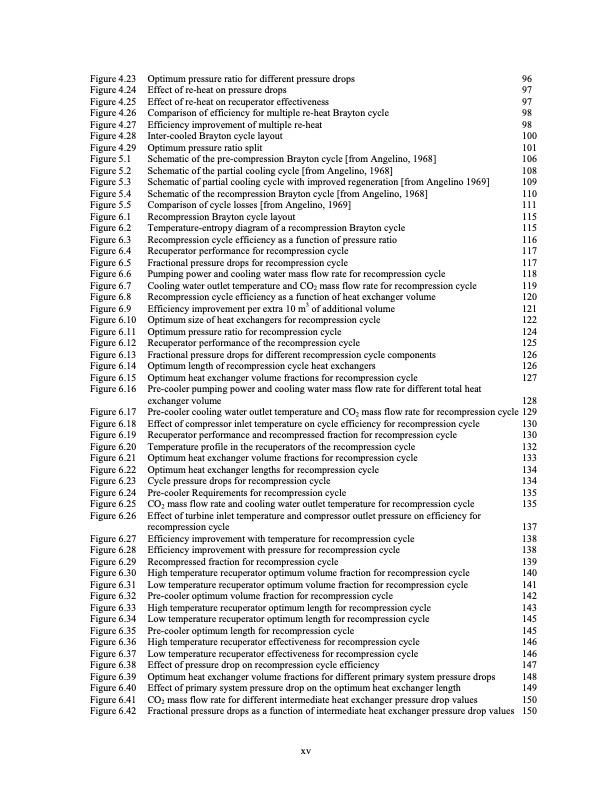

Figure 4.23 Figure 4.24 Figure 4.25 Figure 4.26 Figure 4.27 Figure 4.28 Figure 4.29 Figure 5.1 Figure 5.2 Figure 5.3 Figure 5.4 Figure 5.5 Figure 6.1 Figure 6.2 Figure 6.3 Figure 6.4 Figure 6.5 Figure 6.6 Figure 6.7 Figure 6.8 Figure 6.9 Figure 6.10 Figure 6.11 Figure 6.12 Figure 6.13 Figure 6.14 Figure 6.15 Figure 6.16 Figure 6.17 Figure 6.18 Figure 6.19 Figure 6.20 Figure 6.21 Figure 6.22 Figure 6.23 Figure 6.24 Figure 6.25 Figure 6.26 Figure 6.27 Figure 6.28 Figure 6.29 Figure 6.30 Figure 6.31 Figure 6.32 Figure 6.33 Figure 6.34 Figure 6.35 Figure 6.36 Figure 6.37 Figure 6.38 Figure 6.39 Figure 6.40 Figure 6.41 Figure 6.42 Optimum pressure ratio for different pressure drops 96 Effect of re-heat on pressure drops 97 Effect of re-heat on recuperator effectiveness 97 Comparison of efficiency for multiple re-heat Brayton cycle 98 Efficiency improvement of multiple re-heat 98 Inter-cooled Brayton cycle layout 100 Optimum pressure ratio split 101 Schematic of the pre-compression Brayton cycle [from Angelino, 1968] 106 Schematic of the partial cooling cycle [from Angelino, 1968] 108 Schematic of partial cooling cycle with improved regeneration [from Angelino 1969] 109 Schematic of the recompression Brayton cycle [from Angelino, 1968] 110 Comparison of cycle losses [from Angelino, 1969] 111 Recompression Brayton cycle layout 115 Temperature-entropy diagram of a recompression Brayton cycle 115 Recompression cycle efficiency as a function of pressure ratio 116 Recuperator performance for recompression cycle 117 Fractional pressure drops for recompression cycle 117 Pumping power and cooling water mass flow rate for recompression cycle 118 Cooling water outlet temperature and CO2 mass flow rate for recompression cycle 119 Recompression cycle efficiency as a function of heat exchanger volume 120 Efficiency improvement per extra 10 m3 of additional volume 121 Optimum size of heat exchangers for recompression cycle 122 Optimum pressure ratio for recompression cycle 124 Recuperator performance of the recompression cycle 125 Fractional pressure drops for different recompression cycle components 126 Optimum length of recompression cycle heat exchangers 126 Optimum heat exchanger volume fractions for recompression cycle 127 Pre-cooler pumping power and cooling water mass flow rate for different total heat exchanger volume 128 Pre-cooler cooling water outlet temperature and CO2 mass flow rate for recompression cycle 129 Effect of compressor inlet temperature on cycle efficiency for recompression cycle 130 Recuperator performance and recompressed fraction for recompression cycle 130 Temperature profile in the recuperators of the recompression cycle 132 Optimum heat exchanger volume fractions for recompression cycle 133 Optimum heat exchanger lengths for recompression cycle 134 Cycle pressure drops for recompression cycle 134 Pre-cooler Requirements for recompression cycle 135 CO2 mass flow rate and cooling water outlet temperature for recompression cycle 135 Effect of turbine inlet temperature and compressor outlet pressure on efficiency for recompression cycle 137 Efficiency improvement with temperature for recompression cycle 138 Efficiency improvement with pressure for recompression cycle 138 Recompressed fraction for recompression cycle 139 High temperature recuperator optimum volume fraction for recompression cycle 140 Low temperature recuperator optimum volume fraction for recompression cycle 141 Pre-cooler optimum volume fraction for recompression cycle 142 High temperature recuperator optimum length for recompression cycle 143 Low temperature recuperator optimum length for recompression cycle 145 Pre-cooler optimum length for recompression cycle 145 High temperature recuperator effectiveness for recompression cycle 146 Low temperature recuperator effectiveness for recompression cycle 146 Effect of pressure drop on recompression cycle efficiency 147 Optimum heat exchanger volume fractions for different primary system pressure drops 148 Effect of primary system pressure drop on the optimum heat exchanger length 149 CO2 mass flow rate for different intermediate heat exchanger pressure drop values 150 Fractional pressure drops as a function of intermediate heat exchanger pressure drop values 150 xvPDF Image | Supercritical Carbon Dioxide Cycle for Next Generation Nuclear Reactors

PDF Search Title:

Supercritical Carbon Dioxide Cycle for Next Generation Nuclear ReactorsOriginal File Name Searched:

Infinity_dostal.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |