PDF Publication Title:

Text from PDF Page: 023

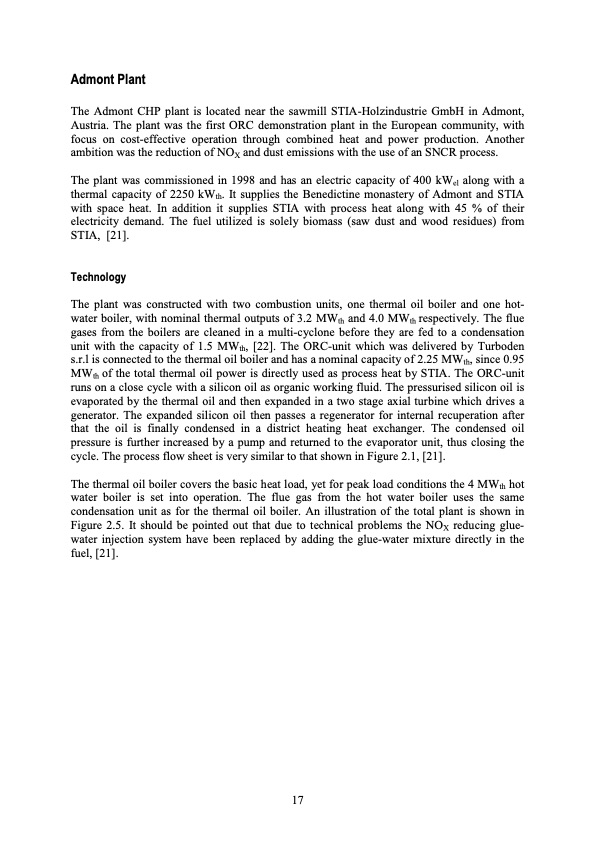

Admont Plant The Admont CHP plant is located near the sawmill STIA-Holzindustrie GmbH in Admont, Austria. The plant was the first ORC demonstration plant in the European community, with focus on cost-effective operation through combined heat and power production. Another ambition was the reduction of NOX and dust emissions with the use of an SNCR process. The plant was commissioned in 1998 and has an electric capacity of 400 kWel along with a thermal capacity of 2250 kWth. It supplies the Benedictine monastery of Admont and STIA with space heat. In addition it supplies STIA with process heat along with 45 % of their electricity demand. The fuel utilized is solely biomass (saw dust and wood residues) from STIA, [21]. Technology The plant was constructed with two combustion units, one thermal oil boiler and one hot- water boiler, with nominal thermal outputs of 3.2 MWth and 4.0 MWth respectively. The flue gases from the boilers are cleaned in a multi-cyclone before they are fed to a condensation unit with the capacity of 1.5 MWth, [22]. The ORC-unit which was delivered by Turboden s.r.l is connected to the thermal oil boiler and has a nominal capacity of 2.25 MWth, since 0.95 MWth of the total thermal oil power is directly used as process heat by STIA. The ORC-unit runs on a close cycle with a silicon oil as organic working fluid. The pressurised silicon oil is evaporated by the thermal oil and then expanded in a two stage axial turbine which drives a generator. The expanded silicon oil then passes a regenerator for internal recuperation after that the oil is finally condensed in a district heating heat exchanger. The condensed oil pressure is further increased by a pump and returned to the evaporator unit, thus closing the cycle. The process flow sheet is very similar to that shown in Figure 2.1, [21]. The thermal oil boiler covers the basic heat load, yet for peak load conditions the 4 MWth hot water boiler is set into operation. The flue gas from the hot water boiler uses the same condensation unit as for the thermal oil boiler. An illustration of the total plant is shown in Figure 2.5. It should be pointed out that due to technical problems the NOX reducing glue- water injection system have been replaced by adding the glue-water mixture directly in the fuel, [21]. 17PDF Image | Biomass Based Small Scale Combined Heat and Power Tech

PDF Search Title:

Biomass Based Small Scale Combined Heat and Power TechOriginal File Name Searched:

LTU_EX_08122_SE.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |