PDF Publication Title:

Text from PDF Page: 054

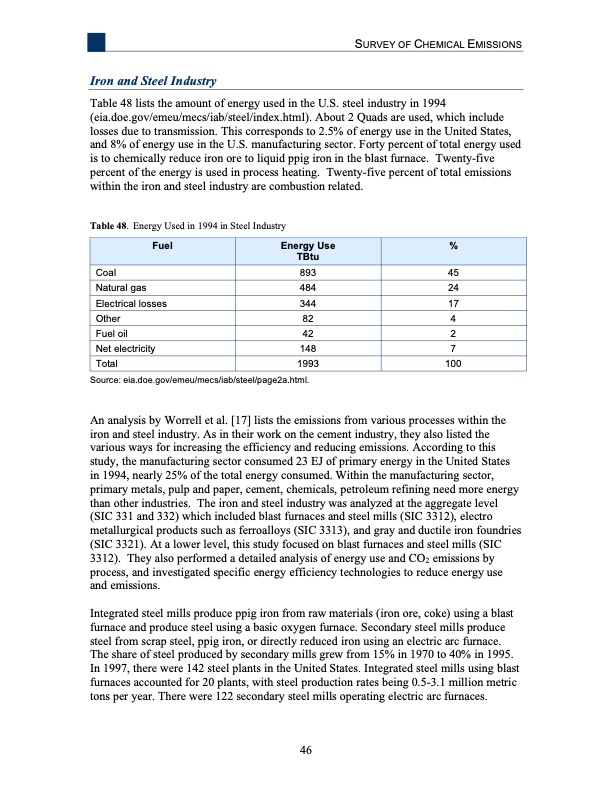

1 SURVEY OF CHEMICAL EMISSIONS Iron and Steel Industry Table 48 lists the amount of energy used in the U.S. steel industry in 1994 (eia.doe.gov/emeu/mecs/iab/steel/index.html). About 2 Quads are used, which include losses due to transmission. This corresponds to 2.5% of energy use in the United States, and 8% of energy use in the U.S. manufacturing sector. Forty percent of total energy used is to chemically reduce iron ore to liquid ppig iron in the blast furnace. Twenty-five percent of the energy is used in process heating. Twenty-five percent of total emissions within the iron and steel industry are combustion related. Table 48. Energy Used in 1994 in Steel Industry Coal Natural gas Electrical losses Other Fuel oil Net electricity Total Fuel Energy Use TBtu 893 484 344 82 42 148 1993 % 45 24 17 4 2 7 100 Source: eia.doe.gov/emeu/mecs/iab/steel/page2a.html. An analysis by Worrell et al. [17] lists the emissions from various processes within the iron and steel industry. As in their work on the cement industry, they also listed the various ways for increasing the efficiency and reducing emissions. According to this study, the manufacturing sector consumed 23 EJ of primary energy in the United States in 1994, nearly 25% of the total energy consumed. Within the manufacturing sector, primary metals, pulp and paper, cement, chemicals, petroleum refining need more energy than other industries. The iron and steel industry was analyzed at the aggregate level (SIC 331 and 332) which included blast furnaces and steel mills (SIC 3312), electro metallurgical products such as ferroalloys (SIC 3313), and gray and ductile iron foundries (SIC 3321). At a lower level, this study focused on blast furnaces and steel mills (SIC 3312). They also performed a detailed analysis of energy use and CO2 emissions by process, and investigated specific energy efficiency technologies to reduce energy use and emissions. Integrated steel mills produce ppig iron from raw materials (iron ore, coke) using a blast furnace and produce steel using a basic oxygen furnace. Secondary steel mills produce steel from scrap steel, ppig iron, or directly reduced iron using an electric arc furnace. The share of steel produced by secondary mills grew from 15% in 1970 to 40% in 1995. In 1997, there were 142 steel plants in the United States. Integrated steel mills using blast furnaces accounted for 20 plants, with steel production rates being 0.5-3.1 million metric tons per year. There were 122 secondary steel mills operating electric arc furnaces. 46PDF Image | Analysis for Recovering Energy from Industrial Waste Heat

PDF Search Title:

Analysis for Recovering Energy from Industrial Waste HeatOriginal File Name Searched:

PNNL_15803.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |