PDF Publication Title:

Text from PDF Page: 013

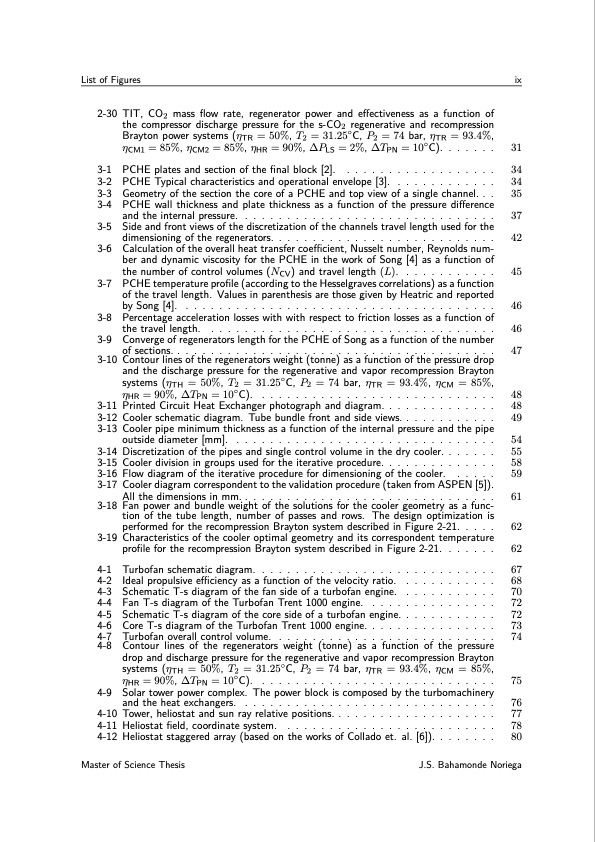

List of Figures ix 2-30 TIT, CO2 mass flow rate, regenerator power and effectiveness as a function of the compressor discharge pressure for the s-CO2 regenerative and recompression Brayton power systems (ηTR = 50%, T2 = 31.25◦C, P2 = 74 bar, ηTR = 93.4%, ηCM1 =85%,ηCM2 =85%,ηHR =90%,∆PLS =2%,∆TPN =10◦C). . . . . . . 31 3-1 PCHEplatesandsectionofthefinalblock[2]. .................. 34 3-2 PCHE Typical characteristics and operational envelope [3]. . . . . . . . . . . . . 34 3-3 Geometry of the section the core of a PCHE and top view of a single channel. . . 35 3-4 PCHE wall thickness and plate thickness as a function of the pressure difference andtheinternalpressure. .............................. 37 3-5 Side and front views of the discretization of the channels travel length used for the dimensioningoftheregenerators........................... 42 3-6 Calculation of the overall heat transfer coefficient, Nusselt number, Reynolds num- ber and dynamic viscosity for the PCHE in the work of Song [4] as a function of thenumberofcontrolvolumes(NCV)andtravellength(L). . . . . . . . . . . . 45 3-7 PCHE temperature profile (according to the Hesselgraves correlations) as a function of the travel length. Values in parenthesis are those given by Heatric and reported bySong[4]. ..................................... 46 3-8 Percentage acceleration losses with with respect to friction losses as a function of thetravellength. .................................. 46 3-9 Converge of regenerators length for the PCHE of Song as a function of the number ofsections....................................... 47 3-10 Contour lines of the regenerators weight (tonne) as a function of the pressure drop and the discharge pressure for the regenerative and vapor recompression Brayton systems (ηTH = 50%, T2 = 31.25◦C, P2 = 74 bar, ηTR = 93.4%, ηCM = 85%, ηHR=90%,∆TPN=10◦C). ............................ 48 3-11 Printed Circuit Heat Exchanger photograph and diagram. . . . . . . . . . . . . . 48 3-12 Cooler schematic diagram. Tube bundle front and side views. . . . . . . . . . . . 49 3-13 Cooler pipe minimum thickness as a function of the internal pressure and the pipe outsidediameter[mm]. ............................... 54 3-14 Discretization of the pipes and single control volume in the dry cooler. . 3-15 Cooler division in groups used for the iterative procedure. . . . . . . . . 3-16 Flow diagram of the iterative procedure for dimensioning of the cooler. 3-17 Cooler diagram correspondent to the validation procedure (taken from ASPEN [5]). Allthedimensionsinmm............................... 61 3-18 Fan power and bundle weight of the solutions for the cooler geometry as a func- tion of the tube length, number of passes and rows. The design optimization is performed for the recompression Brayton system described in Figure 2-21. . . . . 62 3-19 Characteristics of the cooler optimal geometry and its correspondent temperature profile for the recompression Brayton system described in Figure 2-21. . . . . . . 62 4-1 Turbofanschematicdiagram............................. 67 4-2 Ideal propulsive efficiency as a function of the velocity ratio. . . . . . . . . . . . 68 4-3 SchematicT-sdiagramofthefansideofaturbofanengine. . . . . . . . . . . . 70 4-4 FanT-sdiagramoftheTurbofanTrent1000engine. . . . . . . . . . . . . . . . 72 4-5 SchematicT-sdiagramofthecoresideofaturbofanengine. . . . . . . . . . . . 72 4-6 CoreT-sdiagramoftheTurbofanTrent1000engine. . . . . . . . . . . . . . . . 73 4-7 Turbofanoverallcontrolvolume. .......................... 74 4-8 Contour lines of the regenerators weight (tonne) as a function of the pressure drop and discharge pressure for the regenerative and vapor recompression Brayton systems (ηTH = 50%, T2 = 31.25◦C, P2 = 74 bar, ηTR = 93.4%, ηCM = 85%, ηHR=90%,∆TPN=10◦C). ............................ 75 4-9 Solar tower power complex. The power block is composed by the turbomachinery andtheheatexchangers. .............................. 76 4-10 Tower,heliostatandsunrayrelativepositions.. . . . . . . . . . . . . . . . . . . 77 4-11Heliostatfield,coordinatesystem. ......................... 78 4-12 Heliostat staggered array (based on the works of Collado et. al. [6]). . . . . . . . 80 Master of Science Thesis J.S. Bahamonde Noriega ..... 55 ..... 58 ..... 59PDF Image | Design method for s-CO2 gas turbine power plants

PDF Search Title:

Design method for s-CO2 gas turbine power plantsOriginal File Name Searched:

Report_PE_2530.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |