PDF Publication Title:

Text from PDF Page: 006

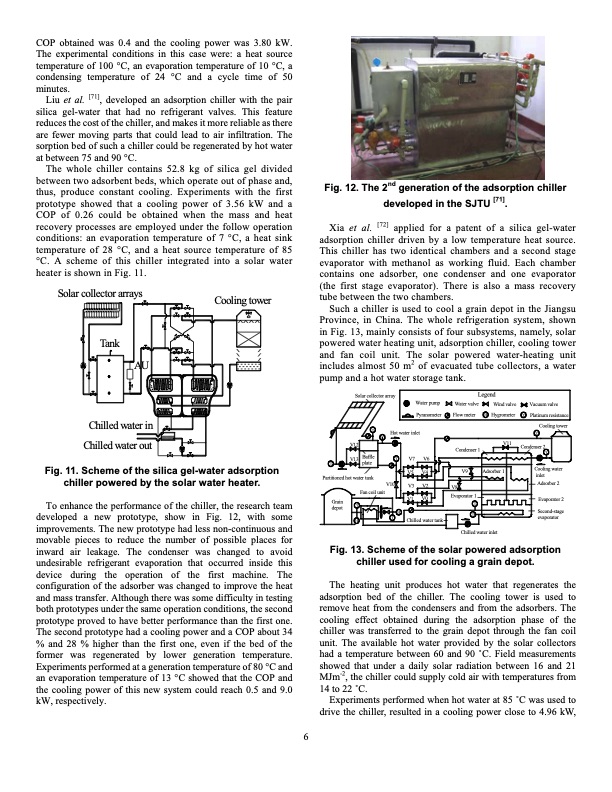

COP obtained was 0.4 and the cooling power was 3.80 kW. The experimental conditions in this case were: a heat source temperature of 100 °C, an evaporation temperature of 10 °C, a condensing temperature of 24 °C and a cycle time of 50 minutes. Liu et al. [71], developed an adsorption chiller with the pair silica gel-water that had no refrigerant valves. This feature reduces the cost of the chiller, and makes it more reliable as there are fewer moving parts that could lead to air infiltration. The sorption bed of such a chiller could be regenerated by hot water at between 75 and 90 °C. The whole chiller contains 52.8 kg of silica gel divided between two adsorbent beds, which operate out of phase and, thus, produce constant cooling. Experiments with the first prototype showed that a cooling power of 3.56 kW and a COP of 0.26 could be obtained when the mass and heat recovery processes are employed under the follow operation conditions: an evaporation temperature of 7 °C, a heat sink temperature of 28 °C, and a heat source temperature of 85 °C. A scheme of this chiller integrated into a solar water heater is shown in Fig. 11. Fig. 12. The 2nd generation of the adsorption chiller developed in the SJTU [71]. Xia et al. [72] applied for a patent of a silica gel-water adsorption chiller driven by a low temperature heat source. This chiller has two identical chambers and a second stage evaporator with methanol as working fluid. Each chamber contains one adsorber, one condenser and one evaporator (the first stage evaporator). There is also a mass recovery tube between the two chambers. Such a chiller is used to cool a grain depot in the Jiangsu Province, in China. The whole refrigeration system, shown in Fig. 13, mainly consists of four subsystems, namely, solar powered water heating unit, adsorption chiller, cooling tower and fan coil unit. The solar powered water-heating unit includes almost 50 m2 of evacuated tube collectors, a water pump and a hot water storage tank. Solar collector arrays Tank AU Chilled water in Chilled water out Cooling tower Solar collector array T T V12 Legend Water pump Pyranometer Water valve Flow meter Condenser 1 V9 V8 Evaporator 1 T H Wind valve Hygrometer Vacuum valve T Platinum resistance Cooling tower T Condenser 2 T Cooling water inlet Adsorber 2 Evaporator 2 Second-stage evaporator 6 Hot water inlet Fig. 13. Scheme of the solar powered adsorption chiller used for cooling a grain depot. The heating unit produces hot water that regenerates the adsorption bed of the chiller. The cooling tower is used to remove heat from the condensers and from the adsorbers. The cooling effect obtained during the adsorption phase of the chiller was transferred to the grain depot through the fan coil unit. The available hot water provided by the solar collectors had a temperature between 60 and 90 ̊C. Field measurements showed that under a daily solar radiation between 16 and 21 MJm-2, the chiller could supply cold air with temperatures from 14to22 ̊C. Experiments performed when hot water at 85 ̊C was used to drive the chiller, resulted in a cooling power close to 4.96 kW, V11 Adsorber 1 V13Baffle TV7V6 plate Fig. 11. Scheme of the silica gel-water adsorption chiller powered by the solar water heater. To enhance the performance of the chiller, the research team developed a new prototype, show in Fig. 12, with some improvements. The new prototype had less non-continuous and movable pieces to reduce the number of possible places for inward air leakage. The condenser was changed to avoid undesirable refrigerant evaporation that occurred inside this device during the operation of the first machine. The configuration of the adsorber was changed to improve the heat and mass transfer. Although there was some difficulty in testing both prototypes under the same operation conditions, the second prototype proved to have better performance than the first one. The second prototype had a cooling power and a COP about 34 % and 28 % higher than the first one, even if the bed of the former was regenerated by lower generation temperature. Experiments performed at a generation temperature of 80 °C and an evaporation temperature of 13 °C showed that the COP and the cooling power of this new system could reach 0.5 and 9.0 kW, respectively. T Partitioned hot water tank Fan coil unit V5 V4 Grain depot T H V10 T V3 V1 V2 V0 H T Chilled water inlet Chilled water tankPDF Image | International Sorption Heat Pump Conference

PDF Search Title:

International Sorption Heat Pump ConferenceOriginal File Name Searched:

rer_8.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |