PDF Publication Title:

Text from PDF Page: 007

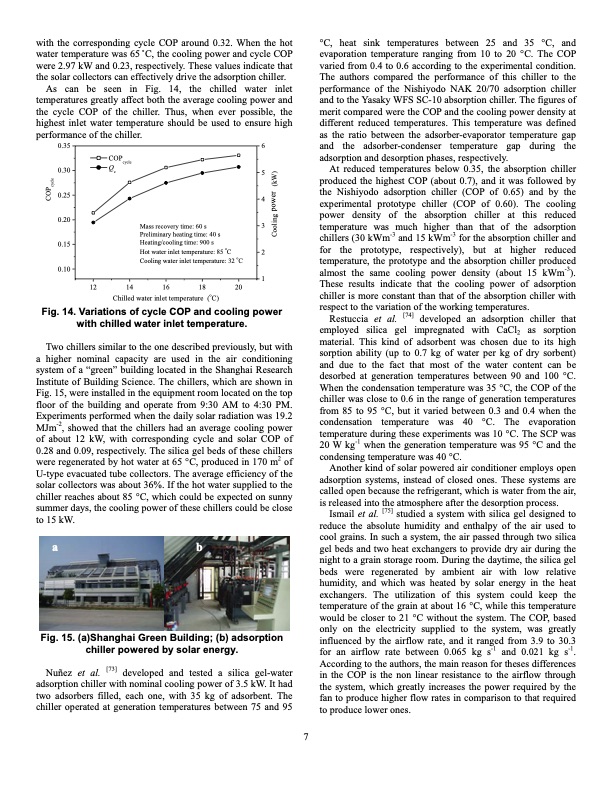

with the corresponding cycle COP around 0.32. When the hot water temperature was 65 ̊C, the cooling power and cycle COP were 2.97 kW and 0.23, respectively. These values indicate that the solar collectors can effectively drive the adsorption chiller. As can be seen in Fig. 14, the chilled water inlet temperatures greatly affect both the average cooling power and the cycle COP of the chiller. Thus, when ever possible, the highest inlet water temperature should be used to ensure high performance of the chiller. 0.35 6 0.30 5 °C, heat sink temperatures between 25 and 35 °C, and evaporation temperature ranging from 10 to 20 °C. The COP varied from 0.4 to 0.6 according to the experimental condition. The authors compared the performance of this chiller to the performance of the Nishiyodo NAK 20/70 adsorption chiller and to the Yasaky WFS SC-10 absorption chiller. The figures of merit compared were the COP and the cooling power density at different reduced temperatures. This temperature was defined as the ratio between the adsorber-evaporator temperature gap and the adsorber-condenser temperature gap during the adsorption and desorption phases, respectively. At reduced temperatures below 0.35, the absorption chiller produced the highest COP (about 0.7), and it was followed by the Nishiyodo adsorption chiller (COP of 0.65) and by the experimental prototype chiller (COP of 0.60). The cooling power density of the absorption chiller at this reduced temperature was much higher than that of the adsorption chillers (30 kWm-3 and 15 kWm-3 for the absorption chiller and for the prototype, respectively), but at higher reduced temperature, the prototype and the absorption chiller produced almost the same cooling power density (about 15 kWm-3). These results indicate that the cooling power of adsorption chiller is more constant than that of the absorption chiller with respect to the variation of the working temperatures. Restuccia et al. [74] developed an adsorption chiller that employed silica gel impregnated with CaCl2 as sorption material. This kind of adsorbent was chosen due to its high sorption ability (up to 0.7 kg of water per kg of dry sorbent) and due to the fact that most of the water content can be desorbed at generation temperatures between 90 and 100 °C. When the condensation temperature was 35 °C, the COP of the chiller was close to 0.6 in the range of generation temperatures from 85 to 95 °C, but it varied between 0.3 and 0.4 when the condensation temperature was 40 °C. The evaporation temperature during these experiments was 10 °C. The SCP was 20 W kg-1 when the generation temperature was 95 °C and the condensing temperature was 40 °C. Another kind of solar powered air conditioner employs open adsorption systems, instead of closed ones. These systems are called open because the refrigerant, which is water from the air, is released into the atmosphere after the desorption process. Ismail et al. [75] studied a system with silica gel designed to reduce the absolute humidity and enthalpy of the air used to cool grains. In such a system, the air passed through two silica gel beds and two heat exchangers to provide dry air during the night to a grain storage room. During the daytime, the silica gel beds were regenerated by ambient air with low relative humidity, and which was heated by solar energy in the heat exchangers. The utilization of this system could keep the temperature of the grain at about 16 °C, while this temperature would be closer to 21 °C without the system. The COP, based only on the electricity supplied to the system, was greatly influenced by the airflow rate, and it ranged from 3.9 to 30.3 for an airflow rate between 0.065 kg s-1 and 0.021 kg s-1. According to the authors, the main reason for theses differences in the COP is the non linear resistance to the airflow through the system, which greatly increases the power required by the fan to produce higher flow rates in comparison to that required to produce lower ones. COPcycle Qc Mass recovery time: 60 s Preliminary heating time: 40 s Heating/cooling time: 900 s Hot water inlet temperature: 85 oC Cooling water inlet temperature: 32 oC 0.25 0.20 0.15 0.10 4 3 2 1 12 14 16 18 20 Chilled water inlet temperature (oC) Fig. 14. Variations of cycle COP and cooling power with chilled water inlet temperature. Two chillers similar to the one described previously, but with a higher nominal capacity are used in the air conditioning system of a “green” building located in the Shanghai Research Institute of Building Science. The chillers, which are shown in Fig. 15, were installed in the equipment room located on the top floor of the building and operate from 9:30 AM to 4:30 PM. Experiments performed when the daily solar radiation was 19.2 MJm-2, showed that the chillers had an average cooling power of about 12 kW, with corresponding cycle and solar COP of 0.28 and 0.09, respectively. The silica gel beds of these chillers were regenerated by hot water at 65 °C, produced in 170 m2 of U-type evacuated tube collectors. The average efficiency of the solar collectors was about 36%. If the hot water supplied to the chiller reaches about 85 °C, which could be expected on sunny summer days, the cooling power of these chillers could be close to 15 kW. ab Fig. 15. (a)Shanghai Green Building; (b) adsorption chiller powered by solar energy. Nuñez et al. [73] developed and tested a silica gel-water adsorption chiller with nominal cooling power of 3.5 kW. It had two adsorbers filled, each one, with 35 kg of adsorbent. The chiller operated at generation temperatures between 75 and 95 7 power Cooling capacity (kW) COPcyclePDF Image | International Sorption Heat Pump Conference

PDF Search Title:

International Sorption Heat Pump ConferenceOriginal File Name Searched:

rer_8.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |