PDF Publication Title:

Text from PDF Page: 009

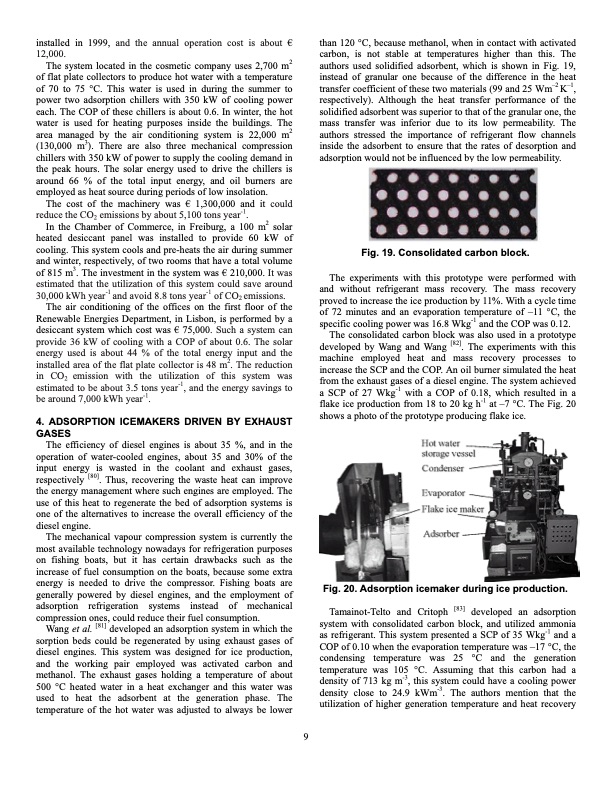

installed in 1999, and the annual operation cost is about € 12,000. The system located in the cosmetic company uses 2,700 m2 of flat plate collectors to produce hot water with a temperature of 70 to 75 °C. This water is used in during the summer to power two adsorption chillers with 350 kW of cooling power each. The COP of these chillers is about 0.6. In winter, the hot water is used for heating purposes inside the buildings. The area managed by the air conditioning system is 22,000 m2 (130,000 m3). There are also three mechanical compression chillers with 350 kW of power to supply the cooling demand in the peak hours. The solar energy used to drive the chillers is around 66 % of the total input energy, and oil burners are employed as heat source during periods of low insolation. The cost of the machinery was € 1,300,000 and it could reduce the CO2 emissions by about 5,100 tons year-1. In the Chamber of Commerce, in Freiburg, a 100 m2 solar heated desiccant panel was installed to provide 60 kW of cooling. This system cools and pre-heats the air during summer and winter, respectively, of two rooms that have a total volume of 815 m3. The investment in the system was € 210,000. It was estimated that the utilization of this system could save around 30,000 kWh year-1 and avoid 8.8 tons year-1 of CO2 emissions. The air conditioning of the offices on the first floor of the Renewable Energies Department, in Lisbon, is performed by a desiccant system which cost was € 75,000. Such a system can provide 36 kW of cooling with a COP of about 0.6. The solar energy used is about 44 % of the total energy input and the installed area of the flat plate collector is 48 m2. The reduction in CO2 emission with the utilization of this system was estimated to be about 3.5 tons year-1, and the energy savings to be around 7,000 kWh year-1. 4. ADSORPTION ICEMAKERS DRIVEN BY EXHAUST GASES The efficiency of diesel engines is about 35 %, and in the operation of water-cooled engines, about 35 and 30% of the input energy is wasted in the coolant and exhaust gases, respectively [80]. Thus, recovering the waste heat can improve the energy management where such engines are employed. The use of this heat to regenerate the bed of adsorption systems is one of the alternatives to increase the overall efficiency of the diesel engine. The mechanical vapour compression system is currently the most available technology nowadays for refrigeration purposes on fishing boats, but it has certain drawbacks such as the increase of fuel consumption on the boats, because some extra energy is needed to drive the compressor. Fishing boats are generally powered by diesel engines, and the employment of adsorption refrigeration systems instead of mechanical compression ones, could reduce their fuel consumption. Wang et al. [81] developed an adsorption system in which the sorption beds could be regenerated by using exhaust gases of diesel engines. This system was designed for ice production, and the working pair employed was activated carbon and methanol. The exhaust gases holding a temperature of about 500 °C heated water in a heat exchanger and this water was used to heat the adsorbent at the generation phase. The temperature of the hot water was adjusted to always be lower than 120 °C, because methanol, when in contact with activated carbon, is not stable at temperatures higher than this. The authors used solidified adsorbent, which is shown in Fig. 19, instead of granular one because of the difference in the heat transfer coefficient of these two materials (99 and 25 Wm–2 K–1, respectively). Although the heat transfer performance of the solidified adsorbent was superior to that of the granular one, the mass transfer was inferior due to its low permeability. The authors stressed the importance of refrigerant flow channels inside the adsorbent to ensure that the rates of desorption and adsorption would not be influenced by the low permeability. Fig. 19. Consolidated carbon block. The experiments with this prototype were performed with and without refrigerant mass recovery. The mass recovery proved to increase the ice production by 11%. With a cycle time of 72 minutes and an evaporation temperature of –11 °C, the specific cooling power was 16.8 Wkg-1 and the COP was 0.12. The consolidated carbon block was also used in a prototype developed by Wang and Wang [82]. The experiments with this machine employed heat and mass recovery processes to increase the SCP and the COP. An oil burner simulated the heat from the exhaust gases of a diesel engine. The system achieved a SCP of 27 Wkg-1 with a COP of 0.18, which resulted in a flake ice production from 18 to 20 kg h-1 at –7 °C. The Fig. 20 shows a photo of the prototype producing flake ice. 9 Fig. 20. Adsorption icemaker during ice production. Tamainot-Telto and Critoph [83] developed an adsorption system with consolidated carbon block, and utilized ammonia as refrigerant. This system presented a SCP of 35 Wkg-1 and a COP of 0.10 when the evaporation temperature was –17 °C, the condensing temperature was 25 °C and the generation temperature was 105 °C. Assuming that this carbon had a density of 713 kg m-3, this system could have a cooling power density close to 24.9 kWm-3. The authors mention that the utilization of higher generation temperature and heat recoveryPDF Image | International Sorption Heat Pump Conference

PDF Search Title:

International Sorption Heat Pump ConferenceOriginal File Name Searched:

rer_8.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |