PDF Publication Title:

Text from PDF Page: 014

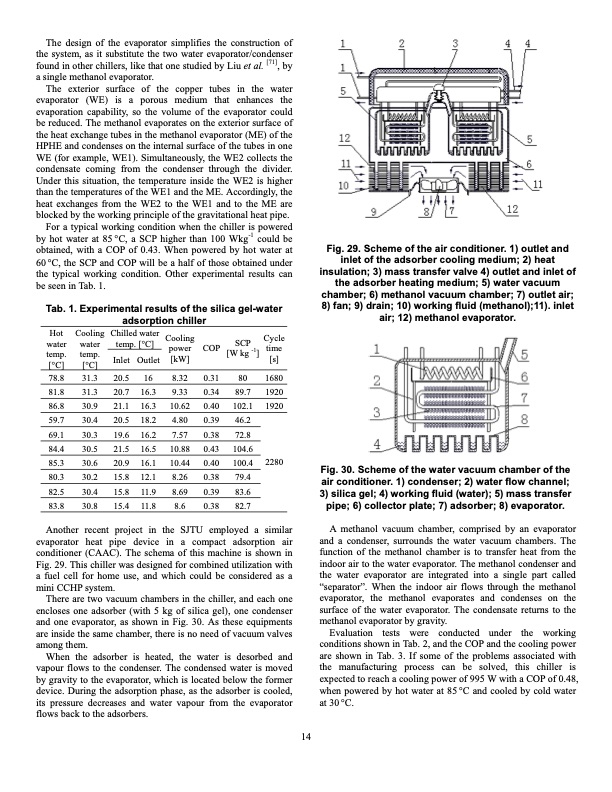

The design of the evaporator simplifies the construction of the system, as it substitute the two water evaporator/condenser found in other chillers, like that one studied by Liu et al. [71], by a single methanol evaporator. The exterior surface of the copper tubes in the water evaporator (WE) is a porous medium that enhances the evaporation capability, so the volume of the evaporator could be reduced. The methanol evaporates on the exterior surface of the heat exchange tubes in the methanol evaporator (ME) of the HPHE and condenses on the internal surface of the tubes in one WE (for example, WE1). Simultaneously, the WE2 collects the condensate coming from the condenser through the divider. Under this situation, the temperature inside the WE2 is higher than the temperatures of the WE1 and the ME. Accordingly, the heat exchanges from the WE2 to the WE1 and to the ME are blocked by the working principle of the gravitational heat pipe. For a typical working condition when the chiller is powered by hot water at 85 °C, a SCP higher than 100 Wkg-1 could be obtained, with a COP of 0.43. When powered by hot water at 60 °C, the SCP and COP will be a half of those obtained under the typical working condition. Other experimental results can be seen in Tab. 1. Tab. 1. Experimental results of the silica gel-water adsorption chiller Fig. 29. Scheme of the air conditioner. 1) outlet and inlet of the adsorber cooling medium; 2) heat insulation; 3) mass transfer valve 4) outlet and inlet of the adsorber heating medium; 5) water vacuum chamber; 6) methanol vacuum chamber; 7) outlet air; 8) fan; 9) drain; 10) working fluid (methanol);11). inlet air; 12) methanol evaporator. Fig. 30. Scheme of the water vacuum chamber of the air conditioner. 1) condenser; 2) water flow channel; 3) silica gel; 4) working fluid (water); 5) mass transfer pipe; 6) collector plate; 7) adsorber; 8) evaporator. A methanol vacuum chamber, comprised by an evaporator and a condenser, surrounds the water vacuum chambers. The function of the methanol chamber is to transfer heat from the indoor air to the water evaporator. The methanol condenser and the water evaporator are integrated into a single part called “separator”. When the indoor air flows through the methanol evaporator, the methanol evaporates and condenses on the surface of the water evaporator. The condensate returns to the methanol evaporator by gravity. Evaluation tests were conducted under the working conditions shown in Tab. 2, and the COP and the cooling power are shown in Tab. 3. If some of the problems associated with the manufacturing process can be solved, this chiller is expected to reach a cooling power of 995 W with a COP of 0.48, when powered by hot water at 85 °C and cooled by cold water at 30 °C. Hot water temp. Cooling Chilled water Cooling water temp. [°C] power Cycle temp. Inlet [°C] [°C] Outlet [kW] 16 8.32 16.3 9.33 16.3 10.62 18.2 4.80 16.2 7.57 16.5 10.88 16.1 10.44 12.1 8.26 11.9 8.69 11.8 8.6 COP SCP-1 time [Wkg ] [s] 0.31 80 1680 0.34 89.7 1920 0.40 102.1 1920 0.39 46.2 0.38 72.8 0.43 104.6 0.40 100.4 2280 0.38 79.4 0.39 83.6 0.38 82.7 78.8 81.8 86.8 59.7 69.1 84.4 85.3 80.3 82.5 83.8 31.3 20.5 31.3 20.7 30.9 21.1 30.4 20.5 30.3 19.6 30.5 21.5 30.6 20.9 30.2 15.8 30.4 15.8 30.8 15.4 Another recent project in the SJTU employed a similar evaporator heat pipe device in a compact adsorption air conditioner (CAAC). The schema of this machine is shown in Fig. 29. This chiller was designed for combined utilization with a fuel cell for home use, and which could be considered as a mini CCHP system. There are two vacuum chambers in the chiller, and each one encloses one adsorber (with 5 kg of silica gel), one condenser and one evaporator, as shown in Fig. 30. As these equipments are inside the same chamber, there is no need of vacuum valves among them. When the adsorber is heated, the water is desorbed and vapour flows to the condenser. The condensed water is moved by gravity to the evaporator, which is located below the former device. During the adsorption phase, as the adsorber is cooled, its pressure decreases and water vapour from the evaporator flows back to the adsorbers. 14PDF Image | International Sorption Heat Pump Conference

PDF Search Title:

International Sorption Heat Pump ConferenceOriginal File Name Searched:

rer_8.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |