PDF Publication Title:

Text from PDF Page: 015

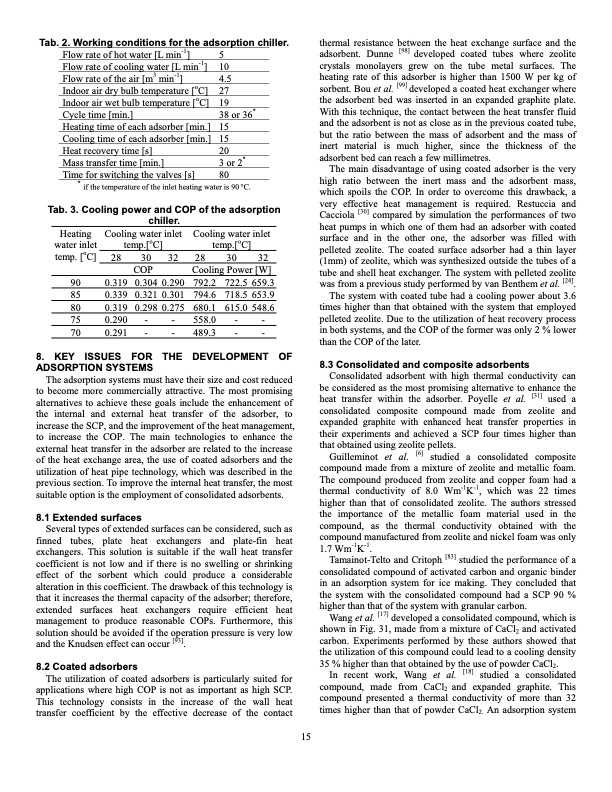

Tab. 2. Working conditions for the adsorption chiller. thermal resistance between the heat exchange surface and the adsorbent. Dunne [98] developed coated tubes where zeolite crystals monolayers grew on the tube metal surfaces. The heating rate of this adsorber is higher than 1500 W per kg of sorbent. Bou et al. [99] developed a coated heat exchanger where the adsorbent bed was inserted in an expanded graphite plate. With this technique, the contact between the heat transfer fluid and the adsorbent is not as close as in the previous coated tube, but the ratio between the mass of adsorbent and the mass of inert material is much higher, since the thickness of the adsorbent bed can reach a few millimetres. The main disadvantage of using coated adsorber is the very high ratio between the inert mass and the adsorbent mass, which spoils the COP. In order to overcome this drawback, a very effective heat management is required. Restuccia and Cacciola [30] compared by simulation the performances of two heat pumps in which one of them had an adsorber with coated surface and in the other one, the adsorber was filled with pelleted zeolite. The coated surface adsorber had a thin layer (1mm) of zeolite, which was synthesized outside the tubes of a tube and shell heat exchanger. The system with pelleted zeolite was from a previous study performed by van Benthem et al. [24]. The system with coated tube had a cooling power about 3.6 times higher than that obtained with the system that employed pelleted zeolite. Due to the utilization of heat recovery process in both systems, and the COP of the former was only 2 % lower than the COP of the later. 8.3 Consolidated and composite adsorbents Consolidated adsorbent with high thermal conductivity can be considered as the most promising alternative to enhance the heat transfer within the adsorber. Poyelle et al. [31] used a consolidated composite compound made from zeolite and expanded graphite with enhanced heat transfer properties in their experiments and achieved a SCP four times higher than that obtained using zeolite pellets. Guilleminot et al. [6] studied a consolidated composite compound made from a mixture of zeolite and metallic foam. The compound produced from zeolite and copper foam had a thermal conductivity of 8.0 Wm-1K-1, which was 22 times higher than that of consolidated zeolite. The authors stressed the importance of the metallic foam material used in the compound, as the thermal conductivity obtained with the compound manufactured from zeolite and nickel foam was only 1.7 Wm-1K-1. Tamainot-Telto and Critoph [83] studied the performance of a consolidated compound of activated carbon and organic binder in an adsorption system for ice making. They concluded that the system with the consolidated compound had a SCP 90 % higher than that of the system with granular carbon. Wang et al. [17] developed a consolidated compound, which is shown in Fig. 31, made from a mixture of CaCl2 and activated carbon. Experiments performed by these authors showed that the utilization of this compound could lead to a cooling density 35 % higher than that obtained by the use of powder CaCl2. In recent work, Wang et al. [18] studied a consolidated compound, made from CaCl2 and expanded graphite. This compound presented a thermal conductivity of more than 32 times higher than that of powder CaCl2. An adsorption system Flow rate of hot water [L min-1] Flow rate of cooling water [L min-1] Flow rate of the air [m3 min-1] 4.5 Indoor air dry bulb temperature [oC] 27 Indoor air wet bulb temperature [oC] Cycle time [min.] Heating time of each adsorber [min.] Cooling time of each adsorber [min.] Heat recovery time [s] Mass transfer time [min.] Time for switching the valves [s] 19 38 or 36* 15 15 20 3or2* 80 5 10 * if the temperature of the inlet heating water is 90 °C. Tab. 3. Cooling power and COP of the adsorption chiller. Heating water inlet temp. [oC] 90 85 80 75 70 Cooling water inlet temp.[oC] Cooling water inlet temp.[oC] 28 30 32 28 30 32 COP Cooling Power [W] 0.319 0.304 0.290 792.2 722.5 659.3 0.339 0.321 0.301 794.6 718.5 653.9 0.319 0.298 0.275 680.1 615.0 548.6 0.290--558.0-- 0.291--489.3-- 8. KEY ISSUES FOR THE DEVELOPMENT OF ADSORPTION SYSTEMS The adsorption systems must have their size and cost reduced to become more commercially attractive. The most promising alternatives to achieve these goals include the enhancement of the internal and external heat transfer of the adsorber, to increase the SCP, and the improvement of the heat management, to increase the COP. The main technologies to enhance the external heat transfer in the adsorber are related to the increase of the heat exchange area, the use of coated adsorbers and the utilization of heat pipe technology, which was described in the previous section. To improve the internal heat transfer, the most suitable option is the employment of consolidated adsorbents. 8.1 Extended surfaces Several types of extended surfaces can be considered, such as finned tubes, plate heat exchangers and plate-fin heat exchangers. This solution is suitable if the wall heat transfer coefficient is not low and if there is no swelling or shrinking effect of the sorbent which could produce a considerable alteration in this coefficient. The drawback of this technology is that it increases the thermal capacity of the adsorber; therefore, extended surfaces heat exchangers require efficient heat management to produce reasonable COPs. Furthermore, this solution should be avoided if the operation pressure is very low and the Knudsen effect can occur [93]. 8.2 Coated adsorbers The utilization of coated adsorbers is particularly suited for applications where high COP is not as important as high SCP. This technology consists in the increase of the wall heat transfer coefficient by the effective decrease of the contact 15PDF Image | International Sorption Heat Pump Conference

PDF Search Title:

International Sorption Heat Pump ConferenceOriginal File Name Searched:

rer_8.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |