PDF Publication Title:

Text from PDF Page: 008

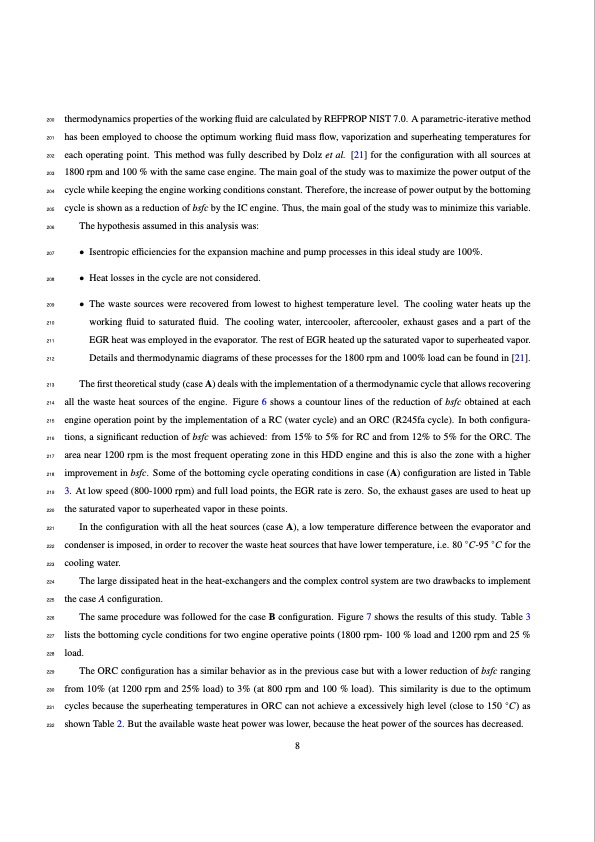

200 thermodynamics properties of the working fluid are calculated by REFPROP NIST 7.0. A parametric-iterative method 201 has been employed to choose the optimum working fluid mass flow, vaporization and superheating temperatures for 202 each operating point. This method was fully described by Dolz et al. [21] for the configuration with all sources at 203 1800 rpm and 100 % with the same case engine. The main goal of the study was to maximize the power output of the 204 cycle while keeping the engine working conditions constant. Therefore, the increase of power output by the bottoming 205 cycle is shown as a reduction of bsfc by the IC engine. Thus, the main goal of the study was to minimize this variable. 206 The hypothesis assumed in this analysis was: 207 • 208 • 209 • 210 211 212 Isentropic efficiencies for the expansion machine and pump processes in this ideal study are 100%. Heat losses in the cycle are not considered. The waste sources were recovered from lowest to highest temperature level. The cooling water heats up the working fluid to saturated fluid. The cooling water, intercooler, aftercooler, exhaust gases and a part of the EGR heat was employed in the evaporator. The rest of EGR heated up the saturated vapor to superheated vapor. Details and thermodynamic diagrams of these processes for the 1800 rpm and 100% load can be found in [21]. 213 The first theoretical study (case A) deals with the implementation of a thermodynamic cycle that allows recovering 214 all the waste heat sources of the engine. Figure 6 shows a countour lines of the reduction of bsfc obtained at each 215 engine operation point by the implementation of a RC (water cycle) and an ORC (R245fa cycle). In both configura- 216 tions, a significant reduction of bsfc was achieved: from 15% to 5% for RC and from 12% to 5% for the ORC. The 217 area near 1200 rpm is the most frequent operating zone in this HDD engine and this is also the zone with a higher 218 improvement in bsfc. Some of the bottoming cycle operating conditions in case (A) configuration are listed in Table 219 3. At low speed (800-1000 rpm) and full load points, the EGR rate is zero. So, the exhaust gases are used to heat up 220 the saturated vapor to superheated vapor in these points. 221 In the configuration with all the heat sources (case A), a low temperature difference between the evaporator and 222 condenser is imposed, in order to recover the waste heat sources that have lower temperature, i.e. 80 ◦C-95 ◦C for the 223 cooling water. 224 The large dissipated heat in the heat-exchangers and the complex control system are two drawbacks to implement 225 the case A configuration. 226 The same procedure was followed for the case B configuration. Figure 7 shows the results of this study. Table 3 227 lists the bottoming cycle conditions for two engine operative points (1800 rpm- 100 % load and 1200 rpm and 25 % 228 load. 229 The ORC configuration has a similar behavior as in the previous case but with a lower reduction of bsfc ranging 230 from 10% (at 1200 rpm and 25% load) to 3% (at 800 rpm and 100 % load). This similarity is due to the optimum 231 cycles because the superheating temperatures in ORC can not achieve a excessively high level (close to 150 ◦C) as 232 shown Table 2. But the available waste heat power was lower, because the heat power of the sources has decreased. 8PDF Image | Methodology to design a bottoming Rankine cycle

PDF Search Title:

Methodology to design a bottoming Rankine cycleOriginal File Name Searched:

PR_2013_05_Dolz.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |