PDF Publication Title:

Text from PDF Page: 007

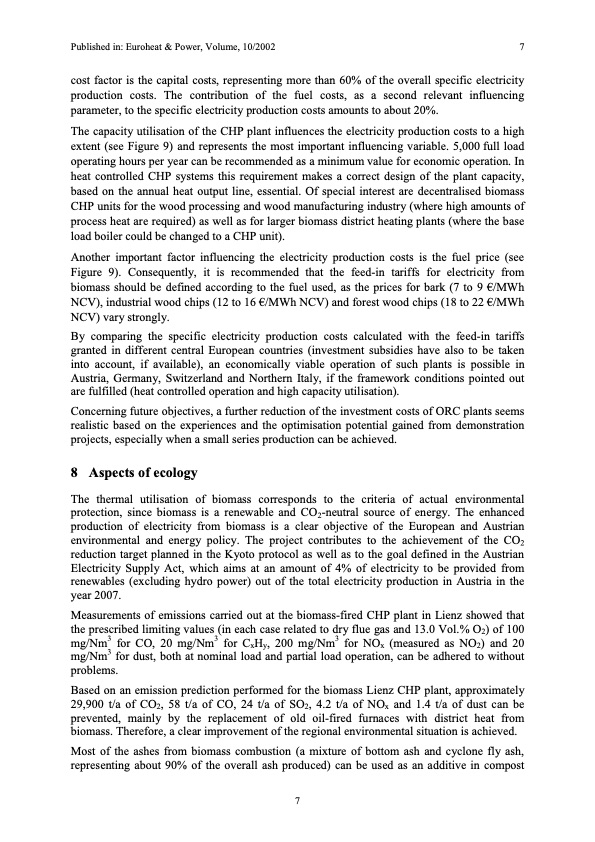

Published in: Euroheat & Power, Volume, 10/2002 7 cost factor is the capital costs, representing more than 60% of the overall specific electricity production costs. The contribution of the fuel costs, as a second relevant influencing parameter, to the specific electricity production costs amounts to about 20%. The capacity utilisation of the CHP plant influences the electricity production costs to a high extent (see Figure 9) and represents the most important influencing variable. 5,000 full load operating hours per year can be recommended as a minimum value for economic operation. In heat controlled CHP systems this requirement makes a correct design of the plant capacity, based on the annual heat output line, essential. Of special interest are decentralised biomass CHP units for the wood processing and wood manufacturing industry (where high amounts of process heat are required) as well as for larger biomass district heating plants (where the base load boiler could be changed to a CHP unit). Another important factor influencing the electricity production costs is the fuel price (see Figure 9). Consequently, it is recommended that the feed-in tariffs for electricity from biomass should be defined according to the fuel used, as the prices for bark (7 to 9 €/MWh NCV), industrial wood chips (12 to 16 €/MWh NCV) and forest wood chips (18 to 22 €/MWh NCV) vary strongly. By comparing the specific electricity production costs calculated with the feed-in tariffs granted in different central European countries (investment subsidies have also to be taken into account, if available), an economically viable operation of such plants is possible in Austria, Germany, Switzerland and Northern Italy, if the framework conditions pointed out are fulfilled (heat controlled operation and high capacity utilisation). Concerning future objectives, a further reduction of the investment costs of ORC plants seems realistic based on the experiences and the optimisation potential gained from demonstration projects, especially when a small series production can be achieved. 8 Aspects of ecology The thermal utilisation of biomass corresponds to the criteria of actual environmental protection, since biomass is a renewable and CO2-neutral source of energy. The enhanced production of electricity from biomass is a clear objective of the European and Austrian environmental and energy policy. The project contributes to the achievement of the CO2 reduction target planned in the Kyoto protocol as well as to the goal defined in the Austrian Electricity Supply Act, which aims at an amount of 4% of electricity to be provided from renewables (excluding hydro power) out of the total electricity production in Austria in the year 2007. Measurements of emissions carried out at the biomass-fired CHP plant in Lienz showed that the prescribed limiting values (in each case related to dry flue gas and 13.0 Vol.% O2) of 100 mg/Nm3 for CO, 20 mg/Nm3 for CxHy, 200 mg/Nm3 for NOx (measured as NO2) and 20 mg/Nm3 for dust, both at nominal load and partial load operation, can be adhered to without problems. Based on an emission prediction performed for the biomass Lienz CHP plant, approximately 29,900t/aofCO2,58t/aofCO,24t/aofSO2,4.2t/aofNOx and1.4t/aofdustcanbe prevented, mainly by the replacement of old oil-fired furnaces with district heat from biomass. Therefore, a clear improvement of the regional environmental situation is achieved. Most of the ashes from biomass combustion (a mixture of bottom ash and cyclone fly ash, representing about 90% of the overall ash produced) can be used as an additive in compost 7PDF Image | ORC process integrated in the biomass CHP plant in Lienz, Austria

PDF Search Title:

ORC process integrated in the biomass CHP plant in Lienz, AustriaOriginal File Name Searched:

report_on_lienz_plant.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |