PDF Publication Title:

Text from PDF Page: 022

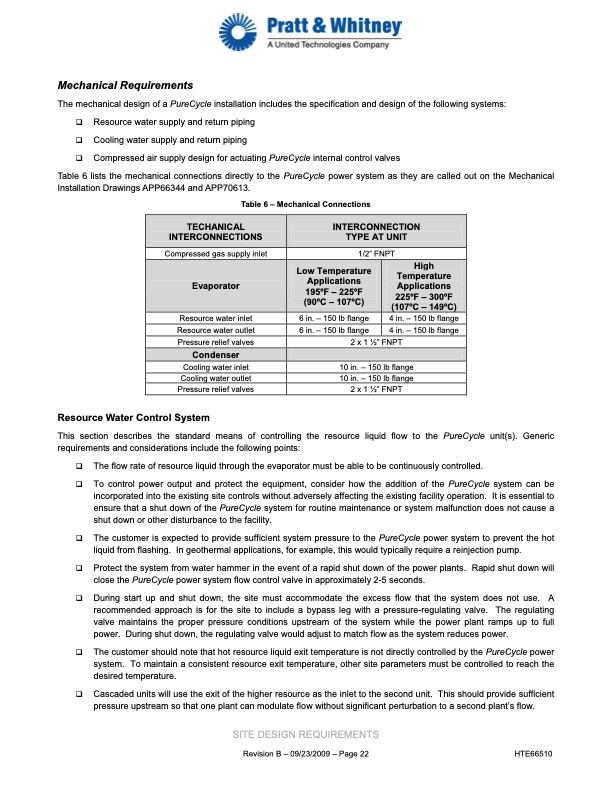

Mechanical Requirements The mechanical design of a PureCycle installation includes the specification and design of the following systems: Resource water supply and return piping Cooling water supply and return piping Compressed air supply design for actuating PureCycle internal control valves Table 6 lists the mechanical connections directly to the PureCycle power system as they are called out on the Mechanical Installation Drawings APP66344 and APP70613. Table 6 – Mechanical Connections TECHANICAL INTERCONNECTIONS INTERCONNECTION TYPE AT UNIT Compressed gas supply inlet Resource water inlet Resource water outlet Pressure relief valves Cooling water inlet Cooling water outlet Pressure relief valves Resource Water Control System 1/2” FNPT 6 in. – 150 lb flange 4 in. – 150 lb flange 6 in. – 150 lb flange 4 in. – 150 lb flange 2 x 1 1⁄2” FNPT 10 in. – 150 lb flange 10 in. – 150 lb flange 2 x 1 1⁄2” FNPT Evaporator Low Temperature Applications 195oF – 225oF (90oC – 107oC) High Temperature Applications 225oF – 300oF (107oC – 149oC) Condenser This section describes the standard means of controlling the resource liquid flow to the PureCycle unit(s). Generic requirements and considerations include the following points: The flow rate of resource liquid through the evaporator must be able to be continuously controlled. To control power output and protect the equipment, consider how the addition of the PureCycle system can be incorporated into the existing site controls without adversely affecting the existing facility operation. It is essential to ensure that a shut down of the PureCycle system for routine maintenance or system malfunction does not cause a shut down or other disturbance to the facility. The customer is expected to provide sufficient system pressure to the PureCycle power system to prevent the hot liquid from flashing. In geothermal applications, for example, this would typically require a reinjection pump. Protect the system from water hammer in the event of a rapid shut down of the power plants. Rapid shut down will close the PureCycle power system flow control valve in approximately 2-5 seconds. During start up and shut down, the site must accommodate the excess flow that the system does not use. A recommended approach is for the site to include a bypass leg with a pressure-regulating valve. The regulating valve maintains the proper pressure conditions upstream of the system while the power plant ramps up to full power. During shut down, the regulating valve would adjust to match flow as the system reduces power. The customer should note that hot resource liquid exit temperature is not directly controlled by the PureCycle power system. To maintain a consistent resource exit temperature, other site parameters must be controlled to reach the desired temperature. Cascaded units will use the exit of the higher resource as the inlet to the second unit. This should provide sufficient pressure upstream so that one plant can modulate flow without significant perturbation to a second plant’s flow. SITE DESIGN REQUIREMENTS Revision B – 09/23/2009 – Page 22 HTE66510PDF Image | PURECYCLE POWER SYSTEM MODEL 280 Application Guide

PDF Search Title:

PURECYCLE POWER SYSTEM MODEL 280 Application GuideOriginal File Name Searched:

Purecycle_application_guide.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |