PDF Publication Title:

Text from PDF Page: 005

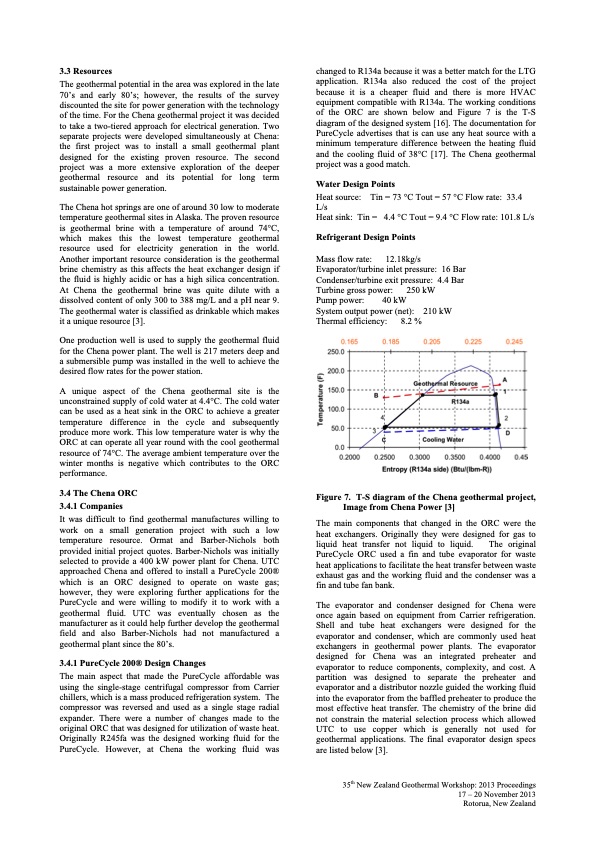

3.3 Resources The geothermal potential in the area was explored in the late 70’s and early 80’s; however, the results of the survey discounted the site for power generation with the technology of the time. For the Chena geothermal project it was decided to take a two-tiered approach for electrical generation. Two separate projects were developed simultaneously at Chena: the first project was to install a small geothermal plant designed for the existing proven resource. The second project was a more extensive exploration of the deeper geothermal resource and its potential for long term sustainable power generation. The Chena hot springs are one of around 30 low to moderate temperature geothermal sites in Alaska. The proven resource is geothermal brine with a temperature of around 74°C, which makes this the lowest temperature geothermal resource used for electricity generation in the world. Another important resource consideration is the geothermal brine chemistry as this affects the heat exchanger design if the fluid is highly acidic or has a high silica concentration. At Chena the geothermal brine was quite dilute with a dissolved content of only 300 to 388 mg/L and a pH near 9. The geothermal water is classified as drinkable which makes it a unique resource [3]. One production well is used to supply the geothermal fluid for the Chena power plant. The well is 217 meters deep and a submersible pump was installed in the well to achieve the desired flow rates for the power station. A unique aspect of the Chena geothermal site is the unconstrained supply of cold water at 4.4°C. The cold water can be used as a heat sink in the ORC to achieve a greater temperature difference in the cycle and subsequently produce more work. This low temperature water is why the ORC at can operate all year round with the cool geothermal resource of 74°C. The average ambient temperature over the winter months is negative which contributes to the ORC performance. 3.4 The Chena ORC 3.4.1 Companies It was difficult to find geothermal manufactures willing to work on a small generation project with such a low temperature resource. Ormat and Barber-Nichols both provided initial project quotes. Barber-Nichols was initially selected to provide a 400 kW power plant for Chena. UTC approached Chena and offered to install a PureCycle 200® which is an ORC designed to operate on waste gas; however, they were exploring further applications for the PureCycle and were willing to modify it to work with a geothermal fluid. UTC was eventually chosen as the manufacturer as it could help further develop the geothermal field and also Barber-Nichols had not manufactured a geothermal plant since the 80’s. 3.4.1 PureCycle 200® Design Changes The main aspect that made the PureCycle affordable was using the single-stage centrifugal compressor from Carrier chillers, which is a mass produced refrigeration system. The compressor was reversed and used as a single stage radial expander. There were a number of changes made to the original ORC that was designed for utilization of waste heat. Originally R245fa was the designed working fluid for the PureCycle. However, at Chena the working fluid was changed to R134a because it was a better match for the LTG application. R134a also reduced the cost of the project because it is a cheaper fluid and there is more HVAC equipment compatible with R134a. The working conditions of the ORC are shown below and Figure 7 is the T-S diagram of the designed system [16]. The documentation for PureCycle advertises that is can use any heat source with a minimum temperature difference between the heating fluid and the cooling fluid of 38°C [17]. The Chena geothermal project was a good match. Water Design Points Heat source: Tin = 73 °C Tout = 57 °C Flow rate: 33.4 L/s Heat sink: Tin = 4.4 °C Tout = 9.4 °C Flow rate: 101.8 L/s Refrigerant Design Points Mass flow rate: 12.18kg/s Evaporator/turbine inlet pressure: 16 Bar Condenser/turbine exit pressure: 4.4 Bar Turbine gross power: 250 kW Pump power: 40 kW System output power (net): Thermal efficiency: 8.2 % 210 kW Figure 7. T-S diagram of the Chena geothermal project, Image from Chena Power [3] The main components that changed in the ORC were the heat exchangers. Originally they were designed for gas to liquid heat transfer not liquid to liquid. The original PureCycle ORC used a fin and tube evaporator for waste heat applications to facilitate the heat transfer between waste exhaust gas and the working fluid and the condenser was a fin and tube fan bank. The evaporator and condenser designed for Chena were once again based on equipment from Carrier refrigeration. Shell and tube heat exchangers were designed for the evaporator and condenser, which are commonly used heat exchangers in geothermal power plants. The evaporator designed for Chena was an integrated preheater and evaporator to reduce components, complexity, and cost. A partition was designed to separate the preheater and evaporator and a distributor nozzle guided the working fluid into the evaporator from the baffled preheater to produce the most effective heat transfer. The chemistry of the brine did not constrain the material selection process which allowed UTC to use copper which is generally not used for geothermal applications. The final evaporator design specs are listed below [3]. 35th New Zealand Geothermal Workshop: 2013 Proceedings 17 – 20 November 2013 Rotorua, New ZealandPDF Image | DEVELOPMENT OF A LOW TEMPERATURE GEOTHERMAL ORGANIC RANKINE

PDF Search Title:

DEVELOPMENT OF A LOW TEMPERATURE GEOTHERMAL ORGANIC RANKINEOriginal File Name Searched:

Taylor_L_Final.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |