PDF Publication Title:

Text from PDF Page: 004

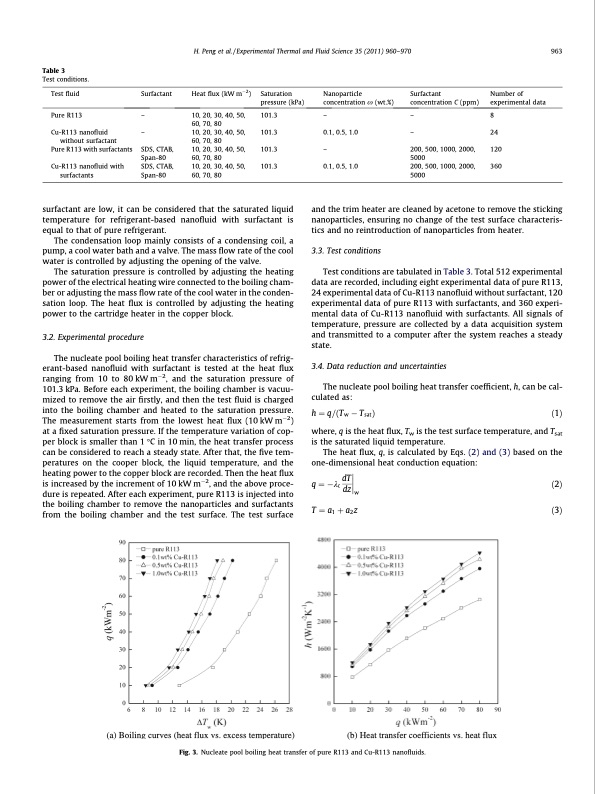

Table 3 Test conditions. Test fluid Pure R113 Cu-R113 nanofluid without surfactant Pure R113 with surfactants Cu-R113 nanofluid with surfactants Surfactant – – SDS, CTAB, Span-80 SDS, CTAB, Span-80 Heat flux (kW m2) 10, 20, 30, 40, 50, 60, 70, 80 10, 20, 30, 40, 50, 60, 70, 80 10, 20, 30, 40, 50, 60, 70, 80 10, 20, 30, 40, 50, 60, 70, 80 Saturation pressure (kPa) 101.3 101.3 101.3 101.3 Nanoparticle concentration x (wt.%) – 0.1, 0.5, 1.0 – 0.1, 0.5, 1.0 Surfactant concentration C (ppm) – – 200, 500, 1000, 2000, 5000 200, 500, 1000, 2000, 5000 Number of experimental data 8 24 120 360 H. Peng et al. / Experimental Thermal and Fluid Science 35 (2011) 960–970 963 surfactant are low, it can be considered that the saturated liquid temperature for refrigerant-based nanofluid with surfactant is equal to that of pure refrigerant. The condensation loop mainly consists of a condensing coil, a pump, a cool water bath and a valve. The mass flow rate of the cool water is controlled by adjusting the opening of the valve. The saturation pressure is controlled by adjusting the heating power of the electrical heating wire connected to the boiling cham- ber or adjusting the mass flow rate of the cool water in the conden- sation loop. The heat flux is controlled by adjusting the heating power to the cartridge heater in the copper block. 3.2. Experimental procedure The nucleate pool boiling heat transfer characteristics of refrig- erant-based nanofluid with surfactant is tested at the heat flux ranging from 10 to 80 kW m2, and the saturation pressure of 101.3 kPa. Before each experiment, the boiling chamber is vacuu- mized to remove the air firstly, and then the test fluid is charged into the boiling chamber and heated to the saturation pressure. The measurement starts from the lowest heat flux (10 kW m2) at a fixed saturation pressure. If the temperature variation of cop- per block is smaller than 1 °C in 10 min, the heat transfer process can be considered to reach a steady state. After that, the five tem- peratures on the cooper block, the liquid temperature, and the heating power to the copper block are recorded. Then the heat flux is increased by the increment of 10 kW m2, and the above proce- dure is repeated. After each experiment, pure R113 is injected into the boiling chamber to remove the nanoparticles and surfactants from the boiling chamber and the test surface. The test surface and the trim heater are cleaned by acetone to remove the sticking nanoparticles, ensuring no change of the test surface characteris- tics and no reintroduction of nanoparticles from heater. 3.3. Test conditions Test conditions are tabulated in Table 3. Total 512 experimental data are recorded, including eight experimental data of pure R113, 24 experimental data of Cu-R113 nanofluid without surfactant, 120 experimental data of pure R113 with surfactants, and 360 experi- mental data of Cu-R113 nanofluid with surfactants. All signals of temperature, pressure are collected by a data acquisition system and transmitted to a computer after the system reaches a steady state. 3.4. Data reduction and uncertainties The nucleate pool boiling heat transfer coefficient, h, can be cal- culated as: h 1⁄4 q=ðTw TsatÞ ð1Þ where, q is the heat flux, Tw is the test surface temperature, and Tsat is the saturated liquid temperature. The heat flux, q, is calculated by Eqs. (2) and (3) based on the one-dimensional heat conduction equation: dT q1⁄4kcdz ð2Þ w T 1⁄4 a1 þ a2z ð3Þ Fig. 3. Nucleate pool boiling heat transfer of pure R113 and Cu-R113 nanofluids. (a) Boiling curves (heat flux vs. excess temperature) (b) Heat transfer coefficients vs. heat fluxPDF Image | Experimental Thermal and Fluid Science 35

PDF Search Title:

Experimental Thermal and Fluid Science 35Original File Name Searched:

SCI_J2011145.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |