PDF Publication Title:

Text from PDF Page: 017

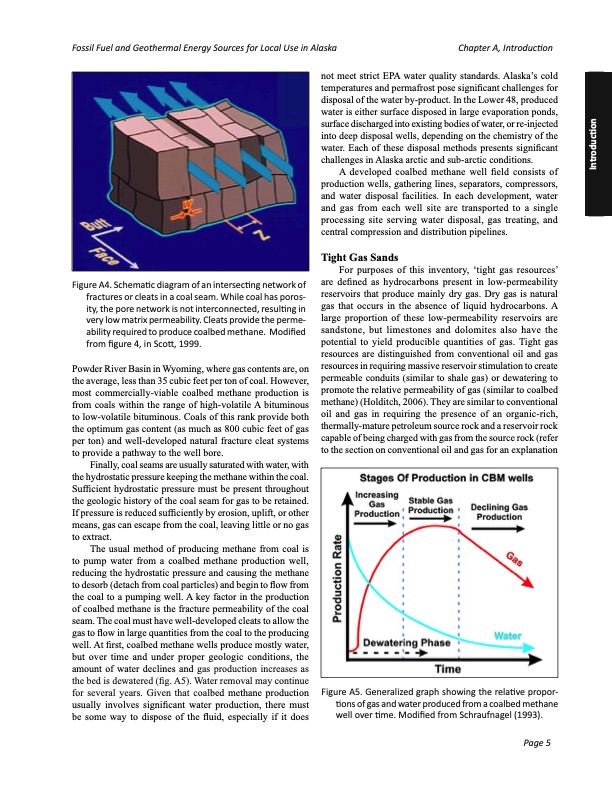

Fossil Fuel and Geothermal Energy Sources for Local Use in Alaska Chapter A, Introduction Figure A4. Schematic diagram of an intersecting network of fractures or cleats in a coal seam. While coal has poros- ity, the pore network is not interconnected, resulting in very low matrix permeability. Cleats provide the perme- ability required to produce coalbed methane. Modified from figure 4, in Scott, 1999. Powder River Basin in Wyoming, where gas contents are, on the average, less than 35 cubic feet per ton of coal. However, most commercially-viable coalbed methane production is from coals within the range of high-volatile A bituminous to low-volatile bituminous. Coals of this rank provide both the optimum gas content (as much as 800 cubic feet of gas per ton) and well-developed natural fracture cleat systems to provide a pathway to the well bore. Finally, coal seams are usually saturated with water, with the hydrostatic pressure keeping the methane within the coal. Sufficient hydrostatic pressure must be present throughout the geologic history of the coal seam for gas to be retained. If pressure is reduced sufficiently by erosion, uplift, or other means, gas can escape from the coal, leaving little or no gas to extract. The usual method of producing methane from coal is to pump water from a coalbed methane production well, reducing the hydrostatic pressure and causing the methane to desorb (detach from coal particles) and begin to flow from the coal to a pumping well. A key factor in the production of coalbed methane is the fracture permeability of the coal seam. The coal must have well-developed cleats to allow the gas to flow in large quantities from the coal to the producing well. At first, coalbed methane wells produce mostly water, but over time and under proper geologic conditions, the amount of water declines and gas production increases as the bed is dewatered (fig. A5). Water removal may continue for several years. Given that coalbed methane production usually involves significant water production, there must be some way to dispose of the fluid, especially if it does not meet strict EPA water quality standards. Alaska’s cold temperatures and permafrost pose significant challenges for disposal of the water by-product. In the Lower 48, produced water is either surface disposed in large evaporation ponds, surface discharged into existing bodies of water, or re-injected into deep disposal wells, depending on the chemistry of the water. Each of these disposal methods presents significant challenges in Alaska arctic and sub-arctic conditions. A developed coalbed methane well field consists of production wells, gathering lines, separators, compressors, and water disposal facilities. In each development, water and gas from each well site are transported to a single processing site serving water disposal, gas treating, and central compression and distribution pipelines. Tight Gas Sands For purposes of this inventory, ‘tight gas resources’ are defined as hydrocarbons present in low-permeability reservoirs that produce mainly dry gas. Dry gas is natural gas that occurs in the absence of liquid hydrocarbons. A large proportion of these low-permeability reservoirs are sandstone, but limestones and dolomites also have the potential to yield producible quantities of gas. Tight gas resources are distinguished from conventional oil and gas resources in requiring massive reservoir stimulation to create permeable conduits (similar to shale gas) or dewatering to promote the relative permeability of gas (similar to coalbed methane) (Holditch, 2006). They are similar to conventional oil and gas in requiring the presence of an organic-rich, thermally-mature petroleum source rock and a reservoir rock capable of being charged with gas from the source rock (refer to the section on conventional oil and gas for an explanation Figure A5. Generalized graph showing the relative propor- tions of gas and water produced from a coalbed methane well over time. Modified from Schraufnagel (1993). Page 5 IntroductionPDF Image | FOSSIL FUEL AND GEOTHERMAL ENERGY SOURCES FOR LOCAL USE

PDF Search Title:

FOSSIL FUEL AND GEOTHERMAL ENERGY SOURCES FOR LOCAL USEOriginal File Name Searched:

sr066.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |