PDF Publication Title:

Text from PDF Page: 039

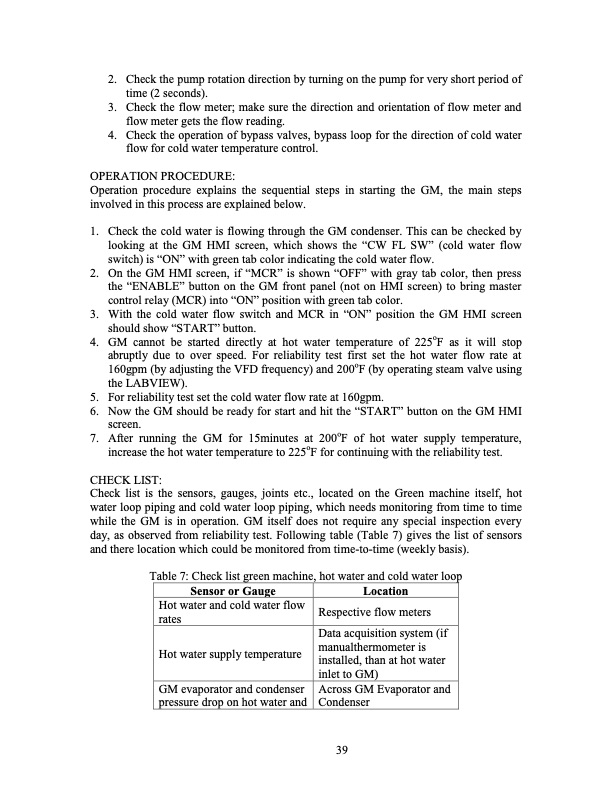

2. Check the pump rotation direction by turning on the pump for very short period of time (2 seconds). 3. Check the flow meter; make sure the direction and orientation of flow meter and flow meter gets the flow reading. 4. Check the operation of bypass valves, bypass loop for the direction of cold water flow for cold water temperature control. OPERATION PROCEDURE: Operation procedure explains the sequential steps in starting the GM, the main steps involved in this process are explained below. 1. Check the cold water is flowing through the GM condenser. This can be checked by looking at the GM HMI screen, which shows the “CW FL SW” (cold water flow switch) is “ON” with green tab color indicating the cold water flow. 2. On the GM HMI screen, if “MCR” is shown “OFF” with gray tab color, then press the “ENABLE” button on the GM front panel (not on HMI screen) to bring master control relay (MCR) into “ON” position with green tab color. 3. With the cold water flow switch and MCR in “ON” position the GM HMI screen should show “START” button. 4. GM cannot be started directly at hot water temperature of 225oF as it will stop abruptly due to over speed. For reliability test first set the hot water flow rate at 160gpm (by adjusting the VFD frequency) and 200oF (by operating steam valve using the LABVIEW). 5. For reliability test set the cold water flow rate at 160gpm. 6. Now the GM should be ready for start and hit the “START” button on the GM HMI screen. 7. After running the GM for 15minutes at 200oF of hot water supply temperature, increase the hot water temperature to 225oF for continuing with the reliability test. CHECK LIST: Check list is the sensors, gauges, joints etc., located on the Green machine itself, hot water loop piping and cold water loop piping, which needs monitoring from time to time while the GM is in operation. GM itself does not require any special inspection every day, as observed from reliability test. Following table (Table 7) gives the list of sensors and there location which could be monitored from time-to-time (weekly basis). Table 7: Check list green machine, hot water and cold water loop Sensor or Gauge Hot water and cold water flow rates GM evaporator and condenser pressure drop on hot water and Location Respective flow meters Across GM Evaporator and Condenser Hot water supply temperature Data acquisition system (if manualthermometer is installed, than at hot water inlet to GM) 39PDF Image | Optimizing Heat Recovery Systems for Power Generation in Rural AK

PDF Search Title:

Optimizing Heat Recovery Systems for Power Generation in Rural AKOriginal File Name Searched:

TCC_Final_Project_Report.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |