PDF Publication Title:

Text from PDF Page: 007

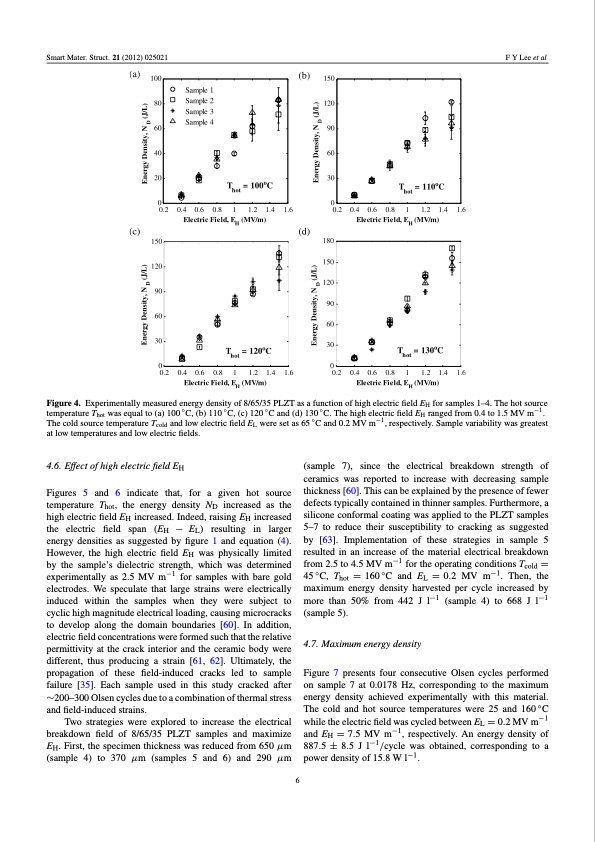

Smart Mater. Struct. 21 (2012) 025021 F Y Lee et al Figure 4. Experimentally measured energy density of 8/65/35 PLZT as a function of high electric field EH for samples 1–4. The hot source temperature Thot was equal to (a) 100 ◦ C, (b) 110 ◦ C, (c) 120 ◦ C and (d) 130 ◦ C. The high electric field EH ranged from 0.4 to 1.5 MV m−1 . The cold source temperature Tcold and low electric field EL were set as 65 ◦ C and 0.2 MV m−1 , respectively. Sample variability was greatest at low temperatures and low electric fields. 4.6. Effect of high electric field EH Figures 5 and 6 indicate that, for a given hot source temperature Thot, the energy density ND increased as the high electric field EH increased. Indeed, raising EH increased the electric field span (EH − EL) resulting in larger energy densities as suggested by figure 1 and equation (4). However, the high electric field EH was physically limited by the sample’s dielectric strength, which was determined experimentally as 2.5 MV m−1 for samples with bare gold electrodes. We speculate that large strains were electrically induced within the samples when they were subject to cyclic high magnitude electrical loading, causing microcracks to develop along the domain boundaries [60]. In addition, electric field concentrations were formed such that the relative permittivity at the crack interior and the ceramic body were different, thus producing a strain [61, 62]. Ultimately, the propagation of these field-induced cracks led to sample failure [35]. Each sample used in this study cracked after ∼200–300 Olsen cycles due to a combination of thermal stress and field-induced strains. Two strategies were explored to increase the electrical breakdown field of 8/65/35 PLZT samples and maximize EH. First, the specimen thickness was reduced from 650 μm (sample 4) to 370 μm (samples 5 and 6) and 290 μm (sample 7), since the electrical breakdown strength of ceramics was reported to increase with decreasing sample thickness [60]. This can be explained by the presence of fewer defects typically contained in thinner samples. Furthermore, a silicone conformal coating was applied to the PLZT samples 5–7 to reduce their susceptibility to cracking as suggested by [63]. Implementation of these strategies in sample 5 resulted in an increase of the material electrical breakdown from 2.5 to 4.5 MV m−1 for the operating conditions Tcold = 45◦C, Thot = 160◦C and EL = 0.2 MV m−1. Then, the maximum energy density harvested per cycle increased by more than 50% from 442 J l−1 (sample 4) to 668 J l−1 (sample 5). 4.7. Maximum energy density Figure 7 presents four consecutive Olsen cycles performed on sample 7 at 0.0178 Hz, corresponding to the maximum energy density achieved experimentally with this material. The cold and hot source temperatures were 25 and 160 ◦ C while the electric field was cycled between EL = 0.2 MV m−1 and EH = 7.5 MV m−1, respectively. An energy density of 887.5 ± 8.5 J l−1/cycle was obtained, corresponding to a power density of 15.8 W l−1 . 6PDF Image | Pyroelectric waste heat harvesting using relaxor ferroelectric

PDF Search Title:

Pyroelectric waste heat harvesting using relaxor ferroelectricOriginal File Name Searched:

SMS2012_8_65_35PLZT.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |