PDF Publication Title:

Text from PDF Page: 010

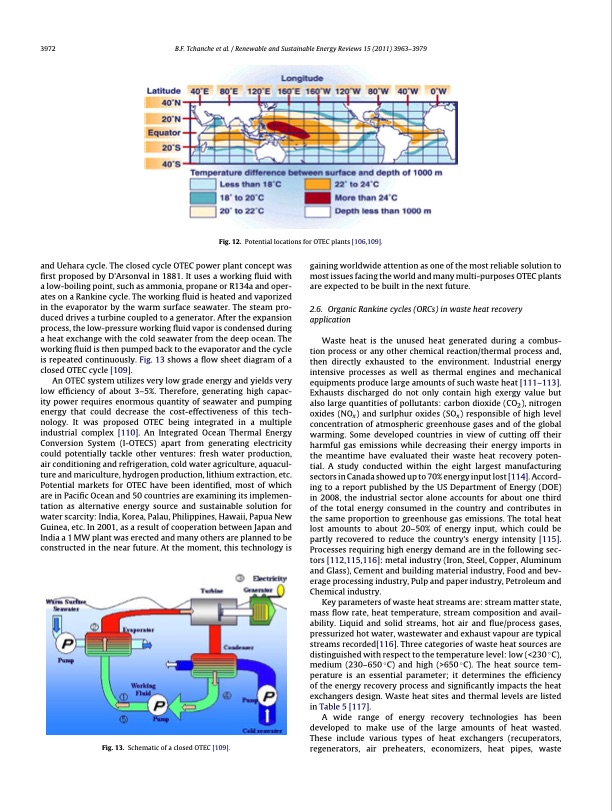

3972 B.F. Tchanche et al. / Renewable and Sustainable Energy Reviews 15 (2011) 3963–3979 and Uehara cycle. The closed cycle OTEC power plant concept was first proposed by D’Arsonval in 1881. It uses a working fluid with a low-boiling point, such as ammonia, propane or R134a and oper- ates on a Rankine cycle. The working fluid is heated and vaporized in the evaporator by the warm surface seawater. The steam pro- duced drives a turbine coupled to a generator. After the expansion process, the low-pressure working fluid vapor is condensed during a heat exchange with the cold seawater from the deep ocean. The working fluid is then pumped back to the evaporator and the cycle is repeated continuously. Fig. 13 shows a flow sheet diagram of a closed OTEC cycle [109]. An OTEC system utilizes very low grade energy and yields very low efficiency of about 3–5%. Therefore, generating high capac- ity power requires enormous quantity of seawater and pumping energy that could decrease the cost-effectiveness of this tech- nology. It was proposed OTEC being integrated in a multiple industrial complex [110]. An Integrated Ocean Thermal Energy Conversion System (I-OTECS) apart from generating electricity could potentially tackle other ventures: fresh water production, air conditioning and refrigeration, cold water agriculture, aquacul- ture and mariculture, hydrogen production, lithium extraction, etc. Potential markets for OTEC have been identified, most of which are in Pacific Ocean and 50 countries are examining its implemen- tation as alternative energy source and sustainable solution for water scarcity: India, Korea, Palau, Philippines, Hawaii, Papua New Guinea, etc. In 2001, as a result of cooperation between Japan and India a 1 MW plant was erected and many others are planned to be constructed in the near future. At the moment, this technology is Fig. 13. Schematic of a closed OTEC [109]. gaining worldwide attention as one of the most reliable solution to most issues facing the world and many multi-purposes OTEC plants are expected to be built in the next future. 2.6. Organic Rankine cycles (ORCs) in waste heat recovery application Waste heat is the unused heat generated during a combus- tion process or any other chemical reaction/thermal process and, then directly exhausted to the environment. Industrial energy intensive processes as well as thermal engines and mechanical equipments produce large amounts of such waste heat [111–113]. Exhausts discharged do not only contain high exergy value but also large quantities of pollutants: carbon dioxide (CO2), nitrogen oxides (NOx) and surlphur oxides (SOx) responsible of high level concentration of atmospheric greenhouse gases and of the global warming. Some developed countries in view of cutting off their harmful gas emissions while decreasing their energy imports in the meantime have evaluated their waste heat recovery poten- tial. A study conducted within the eight largest manufacturing sectors in Canada showed up to 70% energy input lost [114]. Accord- ing to a report published by the US Department of Energy (DOE) in 2008, the industrial sector alone accounts for about one third of the total energy consumed in the country and contributes in the same proportion to greenhouse gas emissions. The total heat lost amounts to about 20–50% of energy input, which could be partly recovered to reduce the country’s energy intensity [115]. Processes requiring high energy demand are in the following sec- tors [112,115,116]: metal industry (Iron, Steel, Copper, Aluminum and Glass), Cement and building material industry, Food and bev- erage processing industry, Pulp and paper industry, Petroleum and Chemical industry. Key parameters of waste heat streams are: stream matter state, mass flow rate, heat temperature, stream composition and avail- ability. Liquid and solid streams, hot air and flue/process gases, pressurized hot water, wastewater and exhaust vapour are typical streams recorded[116]. Three categories of waste heat sources are distinguished with respect to the temperature level: low (<230 ◦ C), medium (230–650◦C) and high (>650◦C). The heat source tem- perature is an essential parameter; it determines the efficiency of the energy recovery process and significantly impacts the heat exchangers design. Waste heat sites and thermal levels are listed in Table 5 [117]. A wide range of energy recovery technologies has been developed to make use of the large amounts of heat wasted. These include various types of heat exchangers (recuperators, regenerators, air preheaters, economizers, heat pipes, waste Fig. 12. Potential locations for OTEC plants [106,109].PDF Image | Renewable and Sustainable Energy Reviews 15

PDF Search Title:

Renewable and Sustainable Energy Reviews 15Original File Name Searched:

science295.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |