PDF Publication Title:

Text from PDF Page: 006

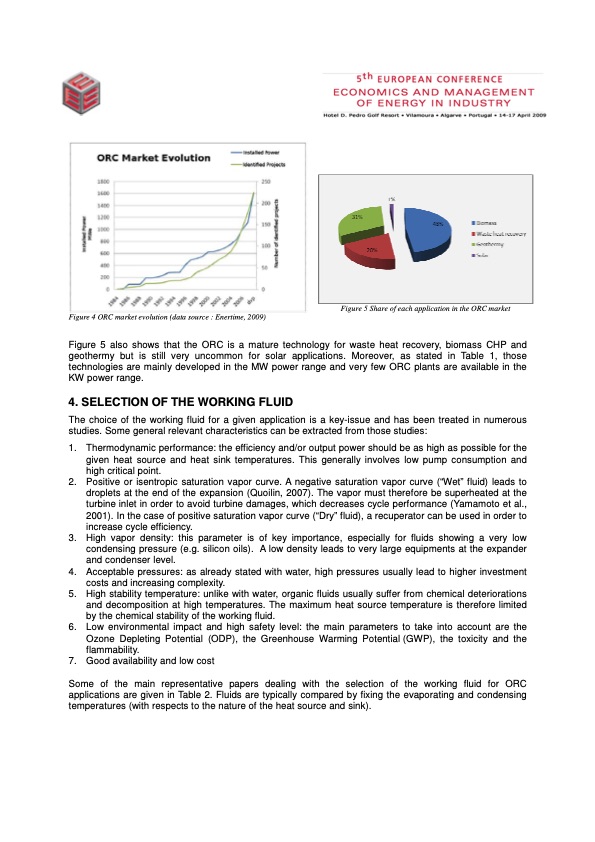

Figure 4 ORC market evolution (data source : Enertime, 2009) Figure 5 also shows that the ORC is a mature technology for waste heat recovery, biomass CHP and geothermy but is still very uncommon for solar applications. Moreover, as stated in Table 1, those technologies are mainly developed in the MW power range and very few ORC plants are available in the KW power range. 4. SELECTION OF THE WORKING FLUID The choice of the working fluid for a given application is a key-issue and has been treated in numerous studies. Some general relevant characteristics can be extracted from those studies: 1. Thermodynamic performance: the efficiency and/or output power should be as high as possible for the given heat source and heat sink temperatures. This generally involves low pump consumption and high critical point. 2. Positive or isentropic saturation vapor curve. A negative saturation vapor curve (“Wet” fluid) leads to droplets at the end of the expansion (Quoilin, 2007). The vapor must therefore be superheated at the turbine inlet in order to avoid turbine damages, which decreases cycle performance (Yamamoto et al., 2001). In the case of positive saturation vapor curve (“Dry” fluid), a recuperator can be used in order to increase cycle efficiency. 3. High vapor density: this parameter is of key importance, especially for fluids showing a very low condensing pressure (e.g. silicon oils). A low density leads to very large equipments at the expander and condenser level. 4. Acceptable pressures: as already stated with water, high pressures usually lead to higher investment costs and increasing complexity. 5. High stability temperature: unlike with water, organic fluids usually suffer from chemical deteriorations and decomposition at high temperatures. The maximum heat source temperature is therefore limited by the chemical stability of the working fluid. 6. Low environmental impact and high safety level: the main parameters to take into account are the Ozone Depleting Potential (ODP), the Greenhouse Warming Potential (GWP), the toxicity and the flammability. 7. Good availability and low cost Some of the main representative papers dealing with the selection of the working fluid for ORC applications are given in Table 2. Fluids are typically compared by fixing the evaporating and condensing temperatures (with respects to the nature of the heat source and sink). Figure 5 Share of each application in the ORC marketPDF Image | Technological and Economical Survey of Organic Rankine Cycle Systems

PDF Search Title:

Technological and Economical Survey of Organic Rankine Cycle SystemsOriginal File Name Searched:

Tech_and_Econ_Survey_of_ORC_Belgium_2009.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |