PDF Publication Title:

Text from PDF Page: 004

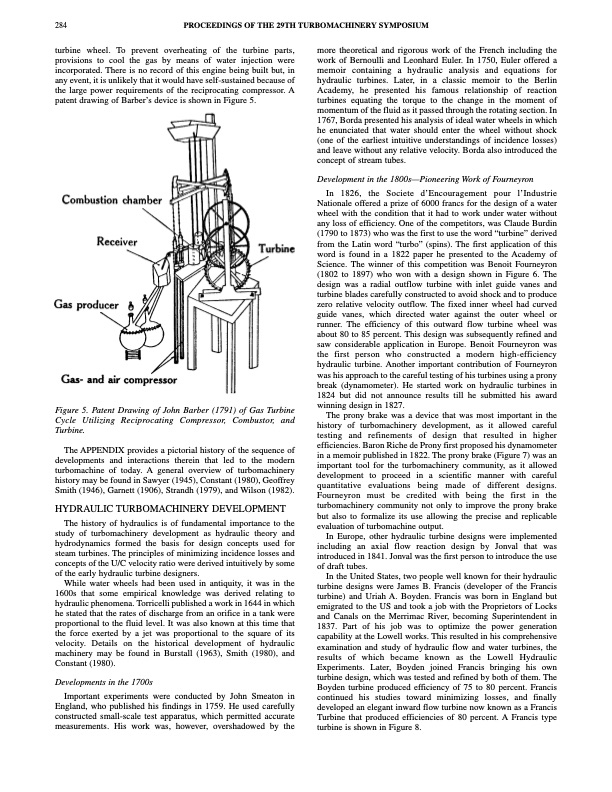

284 PROCEEDINGS OF THE 29TH TURBOMACHINERY SYMPOSIUM turbine wheel. To prevent overheating of the turbine parts, provisions to cool the gas by means of water injection were incorporated. There is no record of this engine being built but, in any event, it is unlikely that it would have self-sustained because of the large power requirements of the reciprocating compressor. A patent drawing of Barber’s device is shown in Figure 5. more theoretical and rigorous work of the French including the work of Bernoulli and Leonhard Euler. In 1750, Euler offered a memoir containing a hydraulic analysis and equations for hydraulic turbines. Later, in a classic memoir to the Berlin Academy, he presented his famous relationship of reaction turbines equating the torque to the change in the moment of momentum of the fluid as it passed through the rotating section. In 1767, Borda presented his analysis of ideal water wheels in which he enunciated that water should enter the wheel without shock (one of the earliest intuitive understandings of incidence losses) and leave without any relative velocity. Borda also introduced the concept of stream tubes. Development in the 1800s—Pioneering Work of Fourneyron In 1826, the Societe d’ Encouragement pour l’ Industrie Nationale offered a prize of 6000 francs for the design of a water wheel with the condition that it had to work under water without any loss of efficiency. One of the competitors, was Claude Burdin (1790 to 1873) who was the first to use the word “turbine” derived from the Latin word “turbo” (spins). The first application of this word is found in a 1822 paper he presented to the Academy of Science. The winner of this competition was Benoit Fourneyron (1802 to 1897) who won with a design shown in Figure 6. The design was a radial outflow turbine with inlet guide vanes and turbine blades carefully constructed to avoid shock and to produce zero relative velocity outflow. The fixed inner wheel had curved guide vanes, which directed water against the outer wheel or runner. The efficiency of this outward flow turbine wheel was about 80 to 85 percent. This design was subsequently refined and saw considerable application in Europe. Benoit Fourneyron was the first person who constructed a modern high-efficiency hydraulic turbine. Another important contribution of Fourneyron was his approach to the careful testing of his turbines using a prony break (dynamometer). He started work on hydraulic turbines in 1824 but did not announce results till he submitted his award winning design in 1827. The prony brake was a device that was most important in the history of turbomachinery development, as it allowed careful testing and refinements of design that resulted in higher efficiencies. Baron Riche de Prony first proposed his dynamometer in a memoir published in 1822. The prony brake (Figure 7) was an important tool for the turbomachinery community, as it allowed development to proceed in a scientific manner with careful quantitative evaluations being made of different designs. Fourneyron must be credited with being the first in the turbomachinery community not only to improve the prony brake but also to formalize its use allowing the precise and replicable evaluation of turbomachine output. In Europe, other hydraulic turbine designs were implemented including an axial flow reaction design by Jonval that was introduced in 1841. Jonval was the first person to introduce the use of draft tubes. In the United States, two people well known for their hydraulic turbine designs were James B. Francis (developer of the Francis turbine) and Uriah A. Boyden. Francis was born in England but emigrated to the US and took a job with the Proprietors of Locks and Canals on the Merrimac River, becoming Superintendent in 1837. Part of his job was to optimize the power generation capability at the Lowell works. This resulted in his comprehensive examination and study of hydraulic flow and water turbines, the results of which became known as the Lowell Hydraulic Experiments. Later, Boyden joined Francis bringing his own turbine design, which was tested and refined by both of them. The Boyden turbine produced efficiency of 75 to 80 percent. Francis continued his studies toward minimizing losses, and finally developed an elegant inward flow turbine now known as a Francis Turbine that produced efficiencies of 80 percent. A Francis type turbine is shown in Figure 8. Figure 5. Patent Drawing of John Barber (1791) of Gas Turbine Cycle Utilizing Reciprocating Compressor, Combustor, and Turbine. The APPENDIX provides a pictorial history of the sequence of developments and interactions therein that led to the modern turbomachine of today. A general overview of turbomachinery history may be found in Sawyer (1945), Constant (1980), Geoffrey Smith (1946), Garnett (1906), Strandh (1979), and Wilson (1982). HYDRAULIC TURBOMACHINERY DEVELOPMENT The history of hydraulics is of fundamental importance to the study of turbomachinery development as hydraulic theory and hydrodynamics formed the basis for design concepts used for steam turbines. The principles of minimizing incidence losses and concepts of the U/C velocity ratio were derived intuitively by some of the early hydraulic turbine designers. While water wheels had been used in antiquity, it was in the 1600s that some empirical knowledge was derived relating to hydraulic phenomena. Torricelli published a work in 1644 in which he stated that the rates of discharge from an orifice in a tank were proportional to the fluid level. It was also known at this time that the force exerted by a jet was proportional to the square of its velocity. Details on the historical development of hydraulic machinery may be found in Burstall (1963), Smith (1980), and Constant (1980). Developments in the 1700s Important experiments were conducted by John Smeaton in England, who published his findings in 1759. He used carefully constructed small-scale test apparatus, which permitted accurate measurements. His work was, however, overshadowed by thePDF Image | THE HISTORICAL EVOLUTION OF TURBOMACHINERY

PDF Search Title:

THE HISTORICAL EVOLUTION OF TURBOMACHINERYOriginal File Name Searched:

t29pg281.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |