PDF Publication Title:

Text from PDF Page: 006

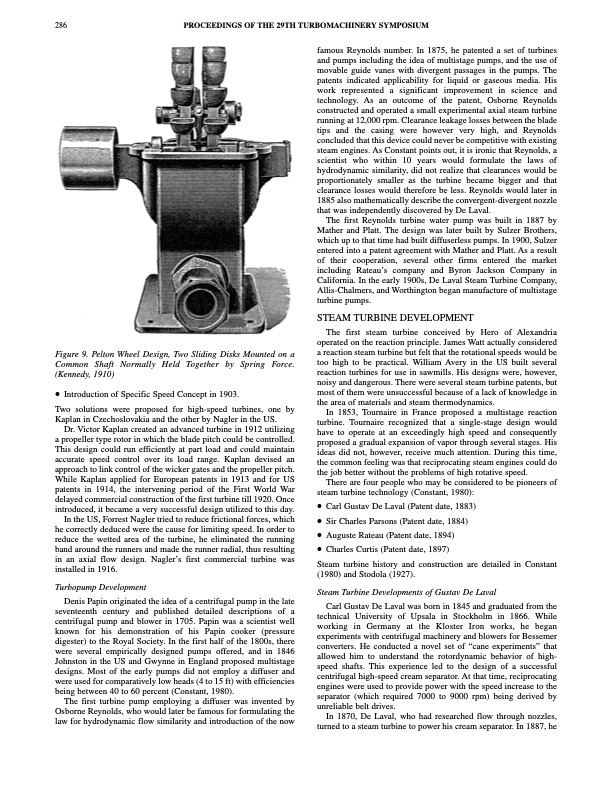

286 PROCEEDINGS OF THE 29TH TURBOMACHINERY SYMPOSIUM Figure 9. Pelton Wheel Design, Two Sliding Disks Mounted on a Common Shaft Normally Held Together by Spring Force. (Kennedy, 1910) • Introduction of Specific Speed Concept in 1903. Two solutions were proposed for high-speed turbines, one by Kaplan in Czechoslovakia and the other by Nagler in the US. Dr. Victor Kaplan created an advanced turbine in 1912 utilizing a propeller type rotor in which the blade pitch could be controlled. This design could run efficiently at part load and could maintain accurate speed control over its load range. Kaplan devised an approach to link control of the wicker gates and the propeller pitch. While Kaplan applied for European patents in 1913 and for US patents in 1914, the intervening period of the First World War delayed commercial construction of the first turbine till 1920. Once introduced, it became a very successful design utilized to this day. In the US, Forrest Nagler tried to reduce frictional forces, which he correctly deduced were the cause for limiting speed. In order to reduce the wetted area of the turbine, he eliminated the running band around the runners and made the runner radial, thus resulting in an axial flow design. Nagler’s first commercial turbine was installed in 1916. Turbopump Development Denis Papin originated the idea of a centrifugal pump in the late seventeenth century and published detailed descriptions of a centrifugal pump and blower in 1705. Papin was a scientist well known for his demonstration of his Papin cooker (pressure digester) to the Royal Society. In the first half of the 1800s, there were several empirically designed pumps offered, and in 1846 Johnston in the US and Gwynne in England proposed multistage designs. Most of the early pumps did not employ a diffuser and were used for comparatively low heads (4 to 15 ft) with efficiencies being between 40 to 60 percent (Constant, 1980). The first turbine pump employing a diffuser was invented by Osborne Reynolds, who would later be famous for formulating the law for hydrodynamic flow similarity and introduction of the now famous Reynolds number. In 1875, he patented a set of turbines and pumps including the idea of multistage pumps, and the use of movable guide vanes with divergent passages in the pumps. The patents indicated applicability for liquid or gaseous media. His work represented a significant improvement in science and technology. As an outcome of the patent, Osborne Reynolds constructed and operated a small experimental axial steam turbine running at 12,000 rpm. Clearance leakage losses between the blade tips and the casing were however very high, and Reynolds concluded that this device could never be competitive with existing steam engines. As Constant points out, it is ironic that Reynolds, a scientist who within 10 years would formulate the laws of hydrodynamic similarity, did not realize that clearances would be proportionately smaller as the turbine became bigger and that clearance losses would therefore be less. Reynolds would later in 1885 also mathematically describe the convergent-divergent nozzle that was independently discovered by De Laval. The first Reynolds turbine water pump was built in 1887 by Mather and Platt. The design was later built by Sulzer Brothers, which up to that time had built diffuserless pumps. In 1900, Sulzer entered into a patent agreement with Mather and Platt. As a result of their cooperation, several other firms entered the market including Rateau’s company and Byron Jackson Company in California. In the early 1900s, De Laval Steam Turbine Company, Allis-Chalmers, and Worthington began manufacture of multistage turbine pumps. STEAM TURBINE DEVELOPMENT The first steam turbine conceived by Hero of Alexandria operated on the reaction principle. James Watt actually considered a reaction steam turbine but felt that the rotational speeds would be too high to be practical. William Avery in the US built several reaction turbines for use in sawmills. His designs were, however, noisy and dangerous. There were several steam turbine patents, but most of them were unsuccessful because of a lack of knowledge in the area of materials and steam thermodynamics. In 1853, Tournaire in France proposed a multistage reaction turbine. Tournaire recognized that a single-stage design would have to operate at an exceedingly high speed and consequently proposed a gradual expansion of vapor through several stages. His ideas did not, however, receive much attention. During this time, the common feeling was that reciprocating steam engines could do the job better without the problems of high rotative speed. There are four people who may be considered to be pioneers of steam turbine technology (Constant, 1980): • Carl Gustav De Laval (Patent date, 1883) • Sir Charles Parsons (Patent date, 1884) • Auguste Rateau (Patent date, 1894) • Charles Curtis (Patent date, 1897) Steam turbine history and construction are detailed in Constant (1980) and Stodola (1927). Steam Turbine Developments of Gustav De Laval Carl Gustav De Laval was born in 1845 and graduated from the technical University of Upsala in Stockholm in 1866. While working in Germany at the Kloster Iron works, he began experiments with centrifugal machinery and blowers for Bessemer converters. He conducted a novel set of “cane experiments” that allowed him to understand the rotordynamic behavior of high- speed shafts. This experience led to the design of a successful centrifugal high-speed cream separator. At that time, reciprocating engines were used to provide power with the speed increase to the separator (which required 7000 to 9000 rpm) being derived by unreliable belt drives. In 1870, De Laval, who had researched flow through nozzles, turned to a steam turbine to power his cream separator. In 1887, hePDF Image | THE HISTORICAL EVOLUTION OF TURBOMACHINERY

PDF Search Title:

THE HISTORICAL EVOLUTION OF TURBOMACHINERYOriginal File Name Searched:

t29pg281.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |