PDF Publication Title:

Text from PDF Page: 007

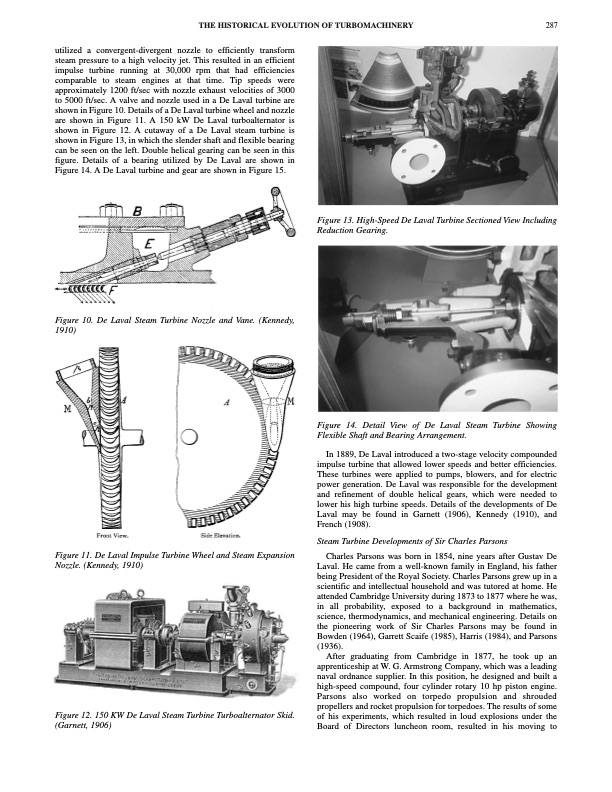

utilized a convergent-divergent nozzle to efficiently transform steam pressure to a high velocity jet. This resulted in an efficient impulse turbine running at 30,000 rpm that had efficiencies comparable to steam engines at that time. Tip speeds were approximately 1200 ft/sec with nozzle exhaust velocities of 3000 to 5000 ft/sec. A valve and nozzle used in a De Laval turbine are shown in Figure 10. Details of a De Laval turbine wheel and nozzle are shown in Figure 11. A 150 kW De Laval turboalternator is shown in Figure 12. A cutaway of a De Laval steam turbine is shown in Figure 13, in which the slender shaft and flexible bearing can be seen on the left. Double helical gearing can be seen in this figure. Details of a bearing utilized by De Laval are shown in Figure 14. A De Laval turbine and gear are shown in Figure 15. THE HISTORICAL EVOLUTION OF TURBOMACHINERY 287 Figure 10. De Laval Steam Turbine Nozzle and Vane. (Kennedy, 1910) Figure 13. High-Speed De Laval Turbine Sectioned View Including Reduction Gearing. Figure 14. Detail View of De Laval Steam Turbine Showing Flexible Shaft and Bearing Arrangement. In 1889, De Laval introduced a two-stage velocity compounded impulse turbine that allowed lower speeds and better efficiencies. These turbines were applied to pumps, blowers, and for electric power generation. De Laval was responsible for the development and refinement of double helical gears, which were needed to lower his high turbine speeds. Details of the developments of De Laval may be found in Garnett (1906), Kennedy (1910), and French (1908). Steam Turbine Developments of Sir Charles Parsons Charles Parsons was born in 1854, nine years after Gustav De Laval. He came from a well-known family in England, his father being President of the Royal Society. Charles Parsons grew up in a scientific and intellectual household and was tutored at home. He attended Cambridge University during 1873 to 1877 where he was, in all probability, exposed to a background in mathematics, science, thermodynamics, and mechanical engineering. Details on the pioneering work of Sir Charles Parsons may be found in Bowden (1964), Garrett Scaife (1985), Harris (1984), and Parsons (1936). After graduating from Cambridge in 1877, he took up an apprenticeship at W. G. Armstrong Company, which was a leading naval ordnance supplier. In this position, he designed and built a high-speed compound, four cylinder rotary 10 hp piston engine. Parsons also worked on torpedo propulsion and shrouded propellers and rocket propulsion for torpedoes. The results of some of his experiments, which resulted in loud explosions under the Board of Directors luncheon room, resulted in his moving to Figure 11. De Laval Impulse Turbine Wheel and Steam Expansion Nozzle. (Kennedy, 1910) Figure 12. 150 KW De Laval Steam Turbine Turboalternator Skid. (Garnett, 1906)PDF Image | THE HISTORICAL EVOLUTION OF TURBOMACHINERY

PDF Search Title:

THE HISTORICAL EVOLUTION OF TURBOMACHINERYOriginal File Name Searched:

t29pg281.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |